Latent hardener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

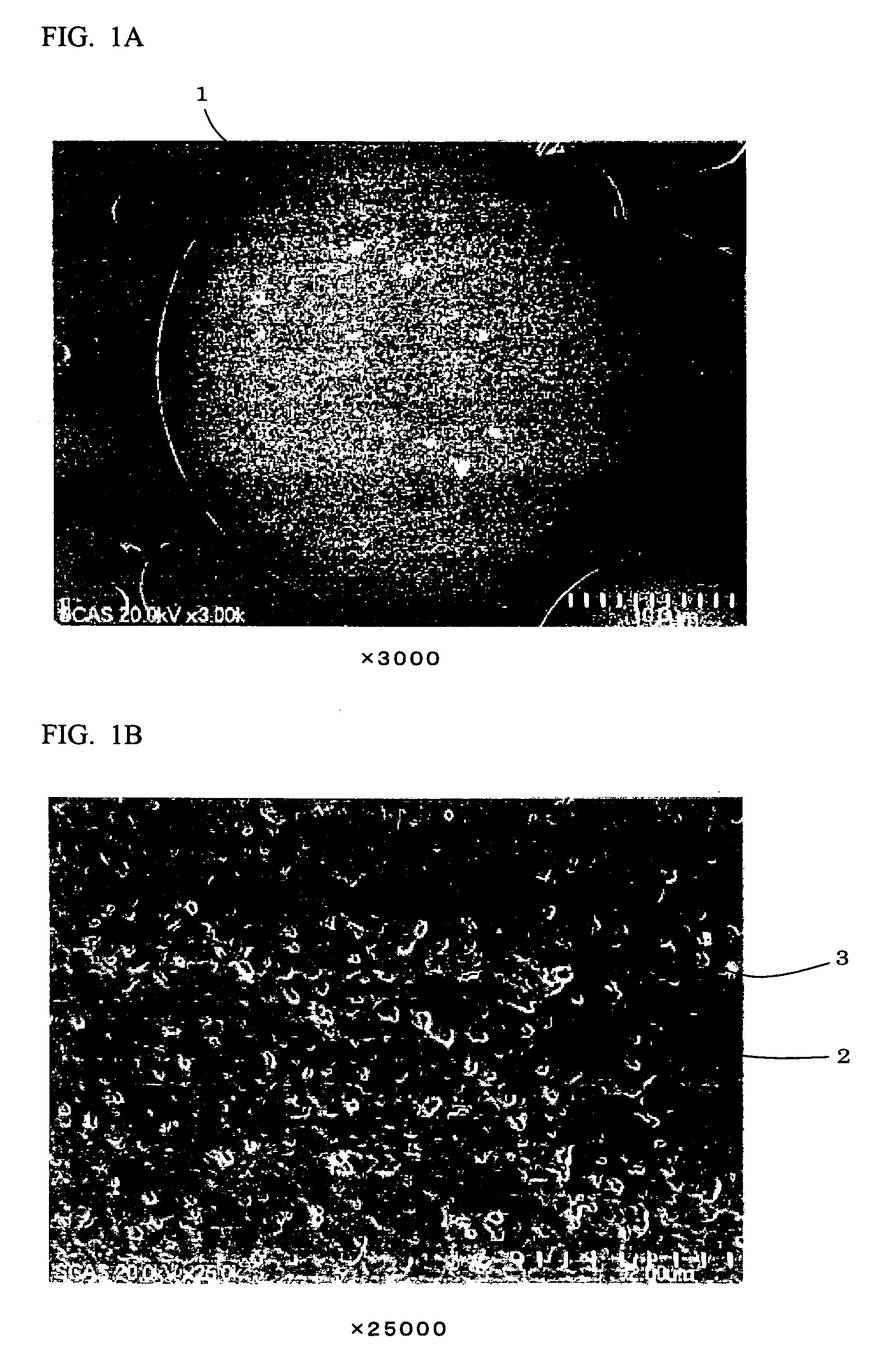

Image

Examples

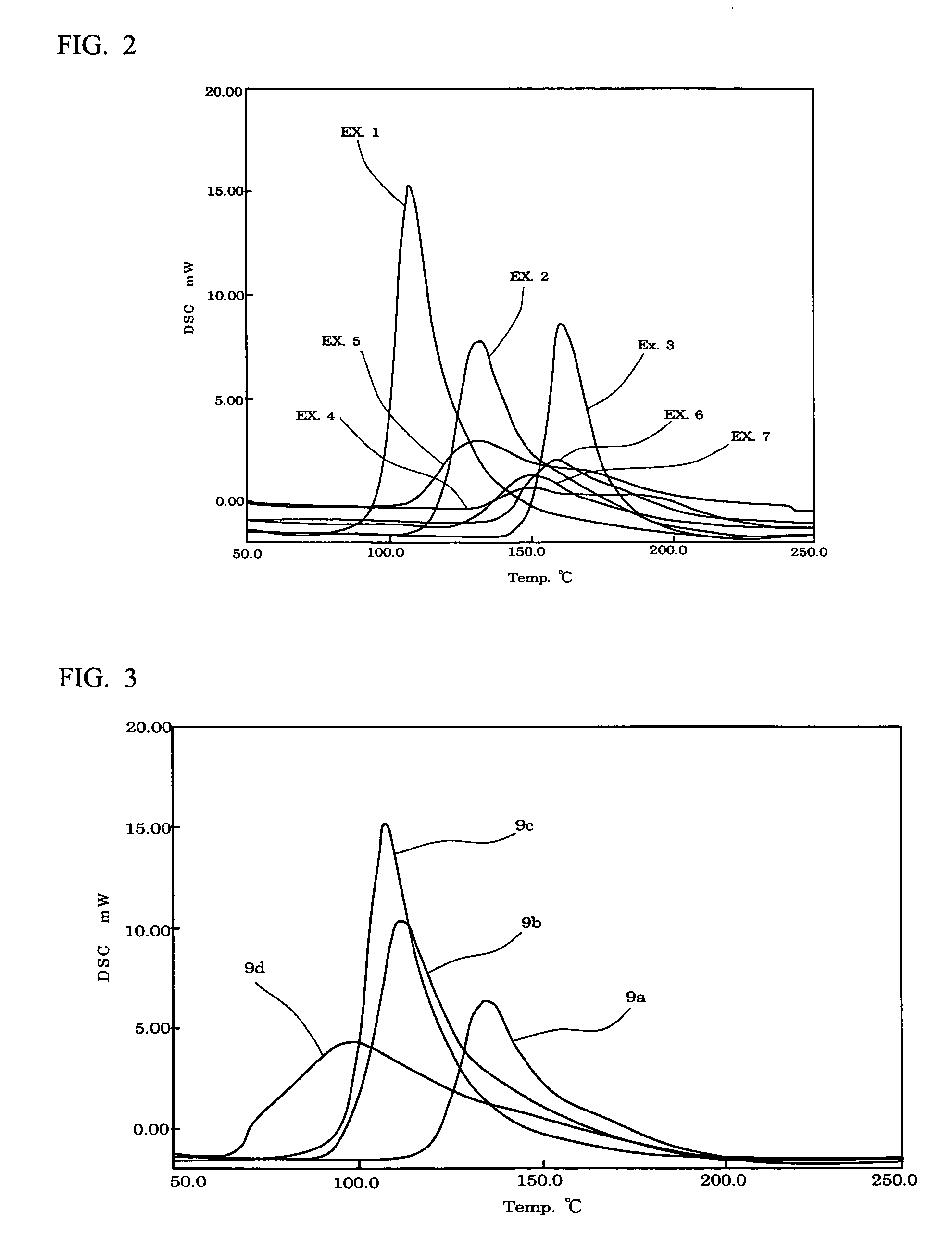

example 1

[0074] 800 parts by weight of distilled water, 0.05 parts by weight of a surfactant (Newrex, available from NOF Co., Ltd.), and 4 parts by weight of polyvinyl alcohol (PVA-205, available from KURARAY Co., Ltd.) to serve as a dispersing agent were placed in a three-liter thermometer-equipped vessel intended for interfacial polymerization, and the mixture was thoroughly mixed. Meanwhile, 11 parts by weight of a 24% isopropanol solution of aluminum monoacetylacetonate bis(ethylacetoacetate) (Alumichelate D, available from KAWAKEN FINE CHEMICALS Co., Ltd.) and 11 parts by weight of a methylenediphenyl-4,4′-diisocyanate (3 mol) / trimethylolpropane (1 mol) adduct (D-109, available from MITSUI TAKEDA CHEMICALS Inc.) were dissolved in 30 parts by weight of ethyl acetate to form an organic phase solution. This solution was added to the above-prepared mixture and the resulting mixture was emulsified by a homogenizer (at 11000 rpm for 10 min). Then, the interfacial polymerization was allowed to...

example 2

[0076] The same procedure was followed as in Example 1, except that toluene diisocyanate (3 mol) / methylenediphenyl-4,4′-diisocyanate (3 mol) / trimethylolpropane (1 mol) adduct (D-103M-2, MITSUI TAKEDA CHEMICALS Inc.) was used in place of methylenediphenyl-4,4′-diisocyanate (3 mol) / trimethylolpropane (1 mol) adduct, to obtain 20 parts by weight of a spherical latent curing agent sized approximately 10 μm.

example 3

[0077] The same procedure was followed as in Example 1, except that toluene diisocyanate (3 mol) / trimethylolpropane (1 mol) adduct (D-103, available from MITSUI TAKEDA CHEMICALS Inc.) was used in place of methylenediphenyl-4,4′-diisocyanate (3 mol) / trimethylolpropane (1 mol) adduct, to obtain 20 parts by weight of a spherical latent curing agent sized approximately 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thermosetting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com