Method for attaching rod-shaped NANO structure to probe holder

a nano structure and rod-shaped technology, applied in the direction of mechanical measurement arrangement, mechanical roughness/irregularity measurement, instruments, etc., can solve the problems of difficult separation, precise attachment of individual nanotubes to desired positions, and difficult purification, separation and manipulation of such entangled nanotubes, etc., to achieve easy manufacturing, reduce assembly time, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

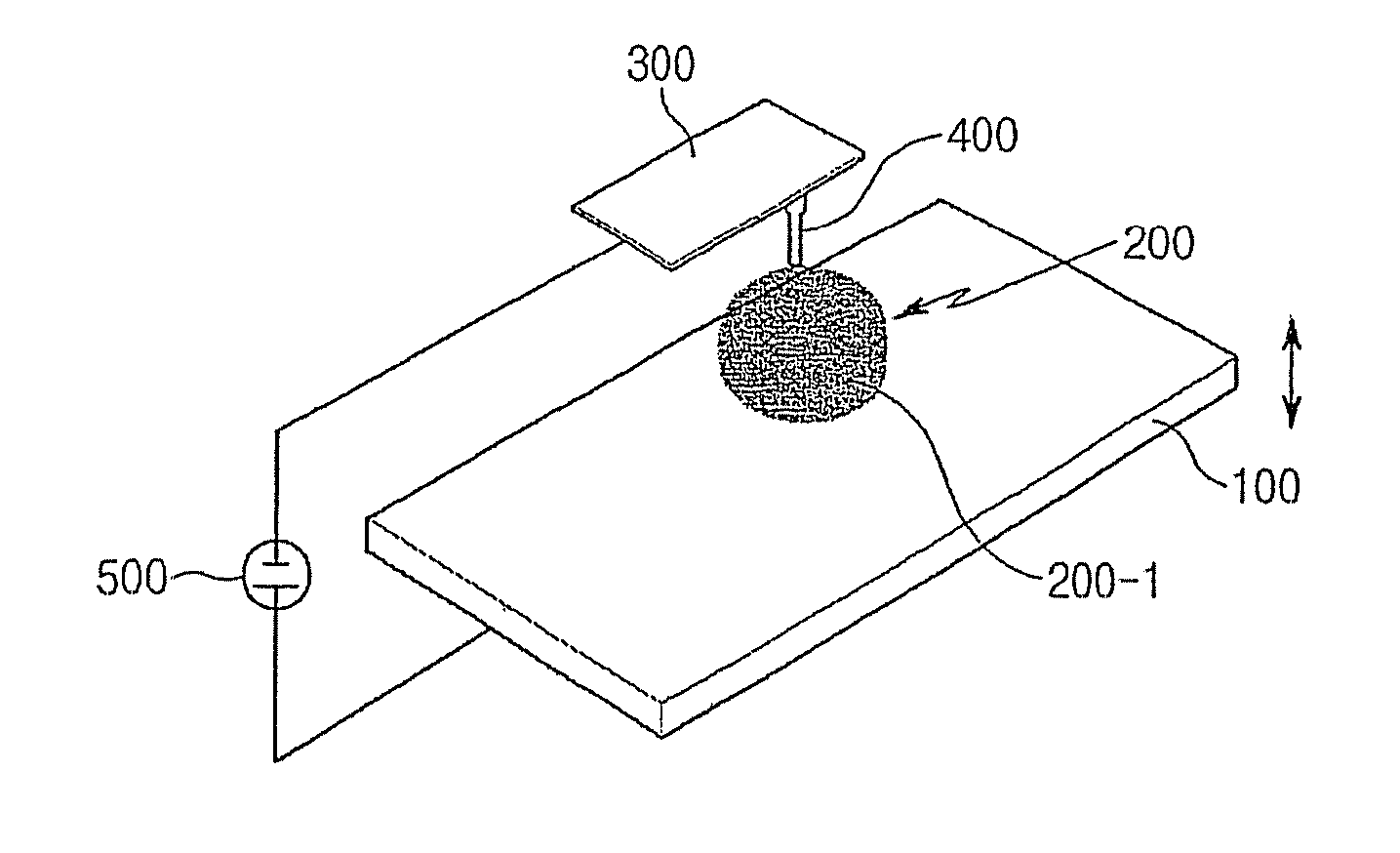

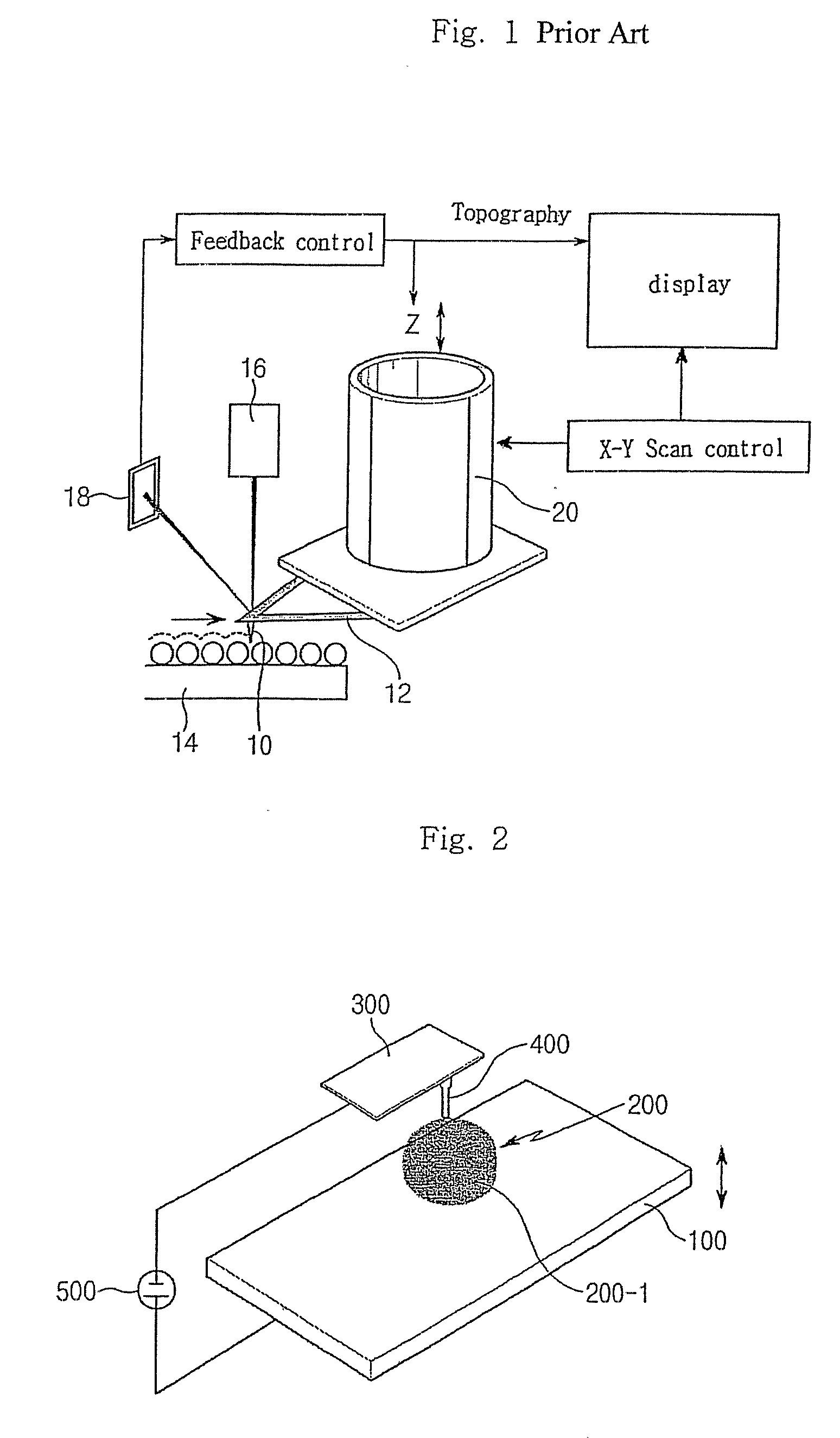

[0036]FIG. 2 is a view for explaining the method for producing a probe with a rod-shaped nano structure attached according to the present invention.

[0037] Referring to FIG. 2, well-conductive electrodes 100 are disposed. Preferably, material with a high conductivity, e.g. Au, Ag, Al, Cu, Ti, and the like, is utilized for the electrodes. On the top portion of the electrodes is a supporter 300, which is also conductive and made of a conductor or coated with a conductor, maintaining a predetermined distance from the electrodes in a horizontal direction. The supporter is usually made of silicon, and to apply the electrodes to this silicon supporter, the supporter can be coated with the metals mentioned above. A holder 400, operating as an electrode, is disposed at a lower portion of the supporter 300, again maintaining a predetermined distance from the electrodes 100. The holder and the supporter can be combined to each other. In such case, silicon is often used to form the shape, and s...

second embodiment

[0050]FIGS. 5a to 5c are views for explaining the method for producing a probe with the rod-shaped nano structure attached according to the present invention.

[0051] With reference to the drawings, a substrate 600 having a groove 600-1 is disposed on a central part of a probe, and electrodes 100 are placed on a top surface of the trench 600-1. The electrodes 100 are formed by coating with layers according to a deposition process, and the substrate 600 for forming the trench 600-1 is layered thereon. Here, the trench can be formed using a general etching process. Since the electrodes and the substrate are made of different materials, the electrodes are etched until they are exposed. On the top portion of the electrodes 100 is a supporter 300, which is conductive and made of conductive materials or coated with a conductor, maintaining a predetermined distance from the electrodes in a horizontal direction. A holder 400, acting as an electrode, is disposed at the lower surface of the sup...

third embodiment

[0057]FIGS. 6a to 6d are views for explaining the method for producing a probe with a rod-shaped nano structure attached according to the present invention.

[0058] As depicted in FIG. 6a, a substrate 600 is installed, and a holder 800 composed of two metal electrodes coated with metals are disposed on both sides of a top surface of the substrate, keeping a predetermined distance from the center. As shown in FIG. 6d, a lower end portion (or base end portion) of the holder 800 to be etched is coated with a sacrificial layer in advance, to etch and lift the holder 800 through a Lift-off process.

[0059] Now turning to FIG. 6b, the solution in which the rod-shaped nano structure 200-1 is dispersed is dropped into between the two electrodes on the substrate 600. At this time, the solution 200 is dropped until adjacent end portions of those two electrodes are immersed into the solution. Then applying a voltage to those two metal electrodes, an electric field is generated between the two ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com