Muffler for an exhaust system

a technology of exhaust system and muffler, which is applied in the direction of gas passages, machines/engines, gas chambers, etc., can solve the problems of increased manufacturing complexity, unwanted negative effect on the interior of the vehicle, and possible design space problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

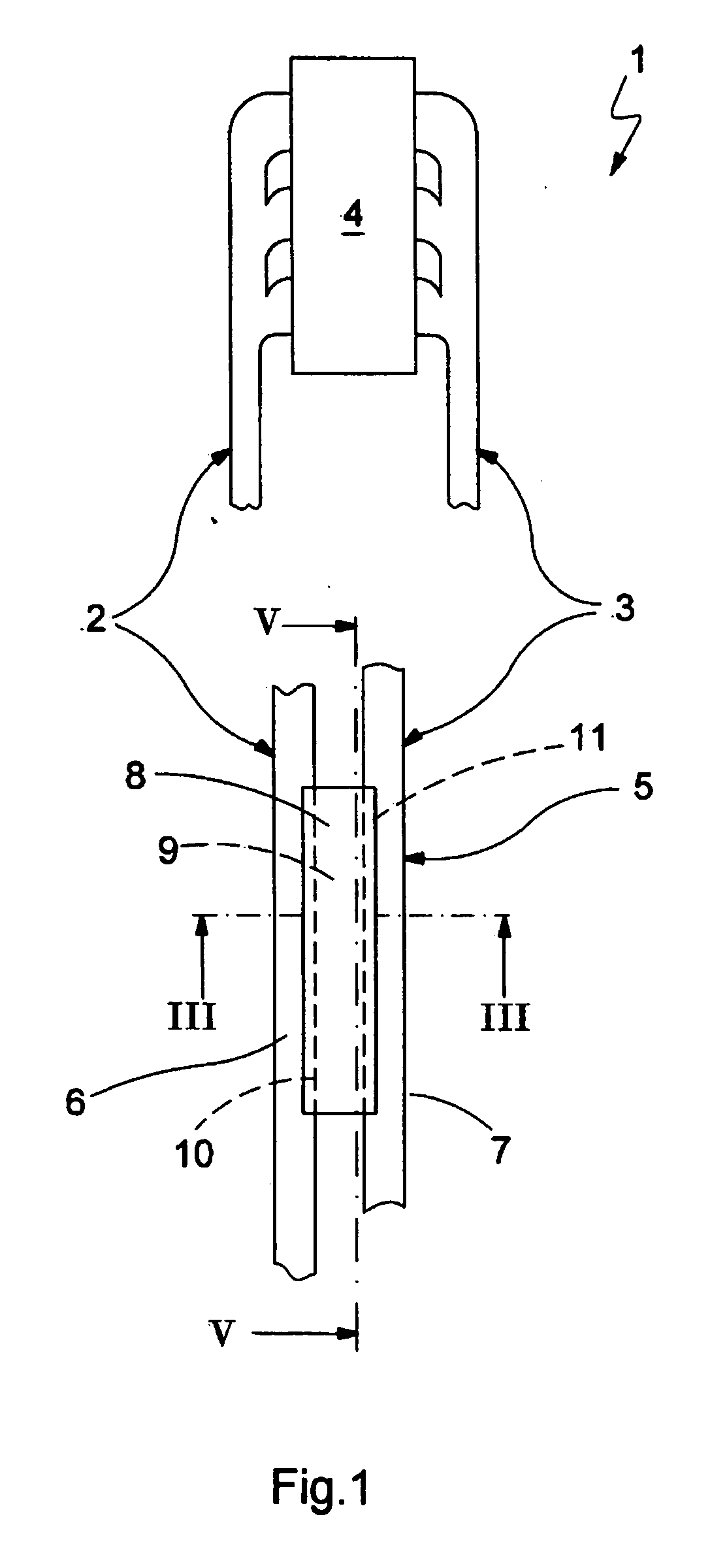

[0015] According to FIG. 1, an exhaust system 1 includes two exhaust lines 2, 3 with the help of which exhaust gas from an internal combustion engine 4 is emitted into an environment of the internal combustion engine 4 and / or a vehicle equipped therewith. Therefore, exhaust gas formed by the internal combustion engine 4 during operation can flow in parallel through the two exhaust lines 2, 3. According to this invention, a muffler 5 is connected jointly to the two exhaust lines 2, 3 and serves to influence the acoustics of the exhaust system 1. The muffler 5 has two pipes carrying the exhaust, namely a first pipe 6 and a second pipe 7.

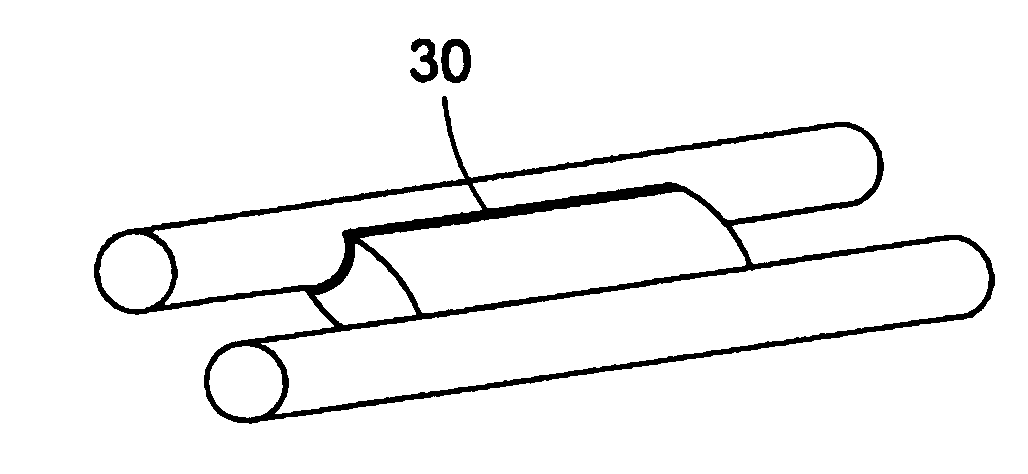

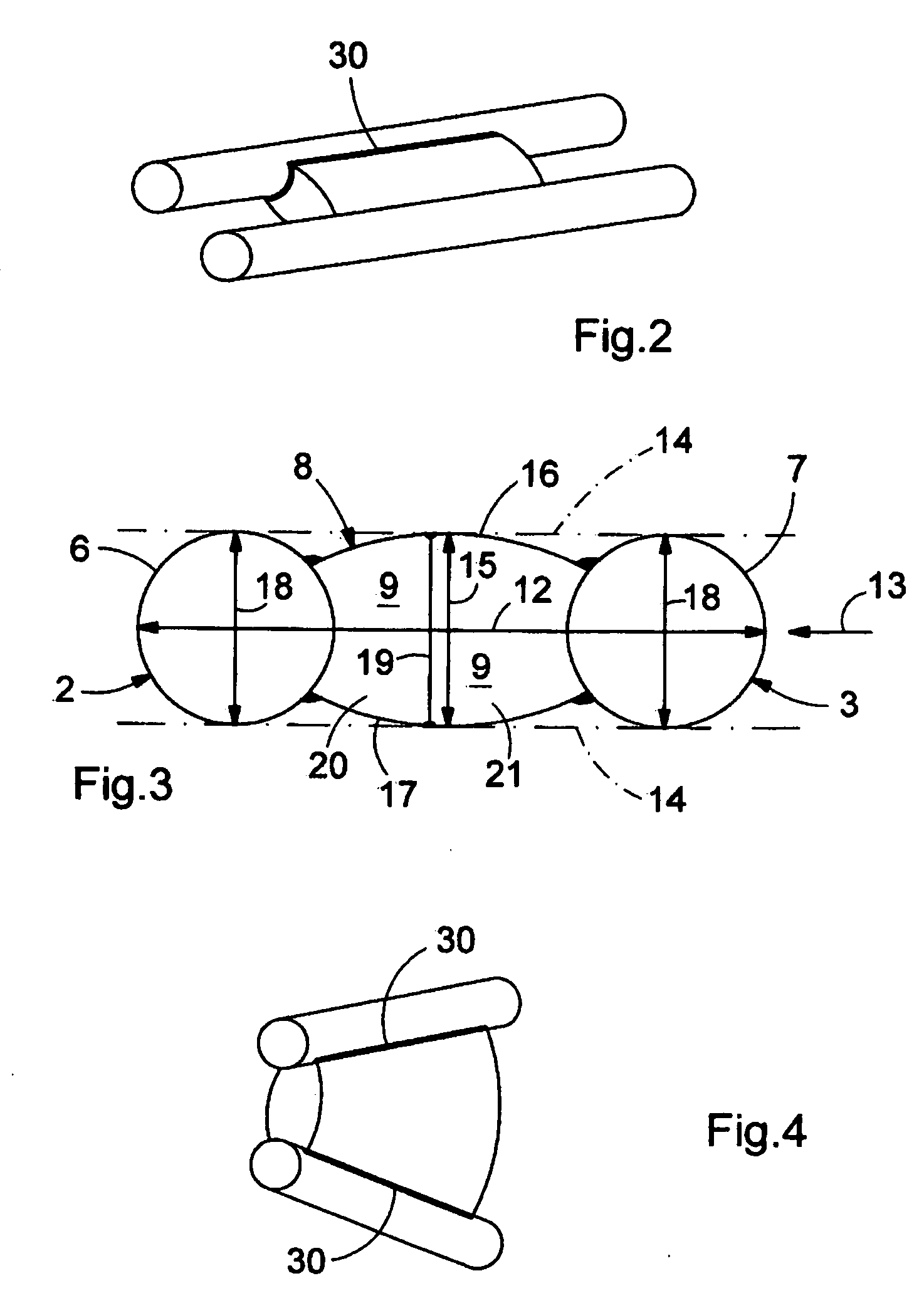

[0016]FIG. 1 shows an embodiment having an integral design. The muffler 5 is integrated into the exhaust system 1 in such a way that the first pipe 6 is formed by a longitudinal section of the first exhaust line 2, while the second pipe 7 is formed by a longitudinal section of the second exhaust line 3. In contrast with that, FIGS. 2 and 4 show two em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com