Extraction of foundation in offshore platforms

a technology of offshore platforms and foundations, applied in the field of offshore technology, can solve the problems of limited capacity of jacking-up systems, inability to provide effective foundation extraction, and soil resistance of conventional water jetting systems, so as to reduce the suction on the base, increase the pore pressure, and reduce the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention may be understood more readily by reference to the following detailed description of certain embodiments of the invention.

[0019] Throughout this application, where publications are referenced, the disclosures of these publications are hereby incorporated by reference, in their entireties, into this application in order to more fully describe the state of art to which this invention pertains.

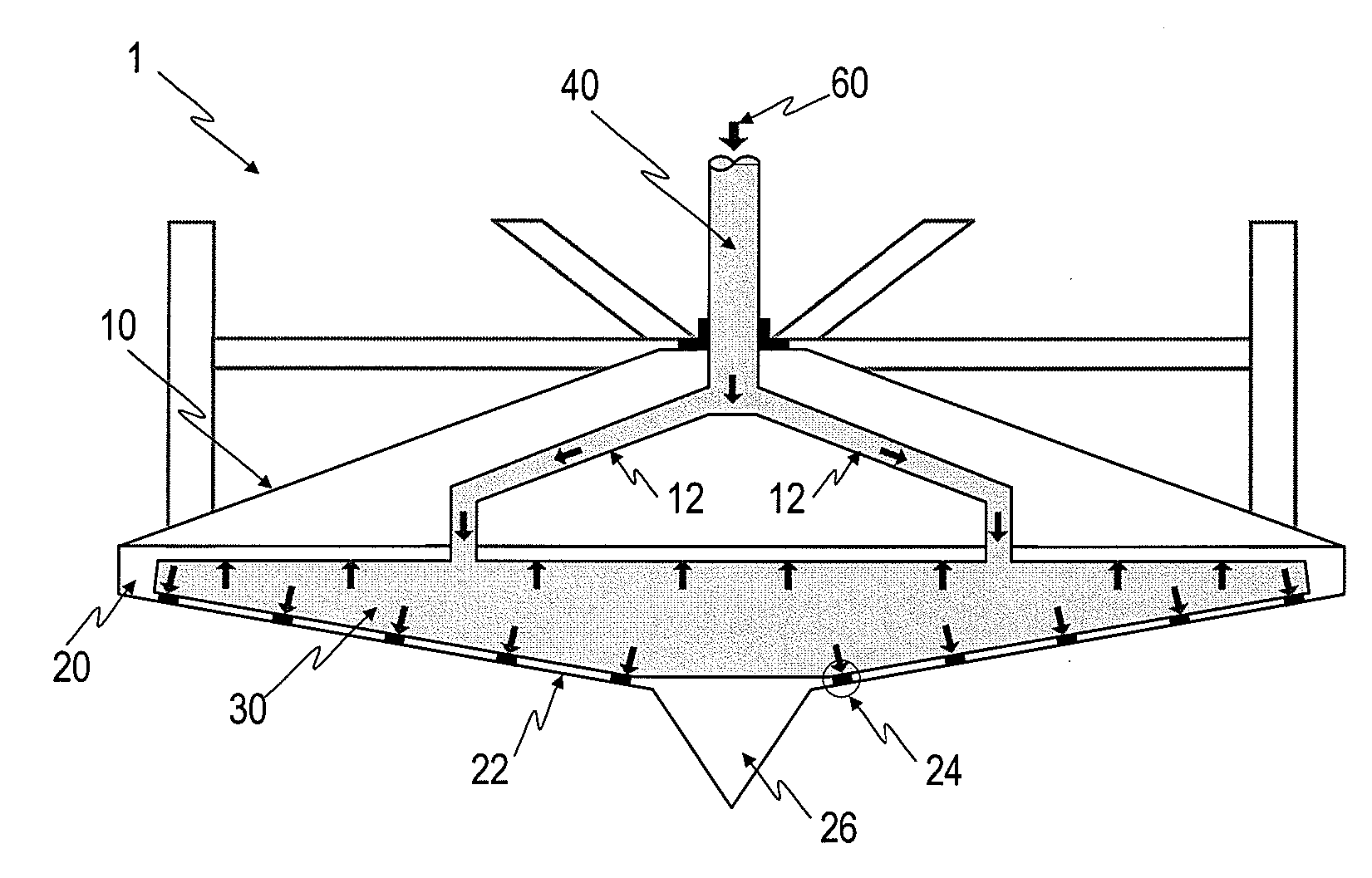

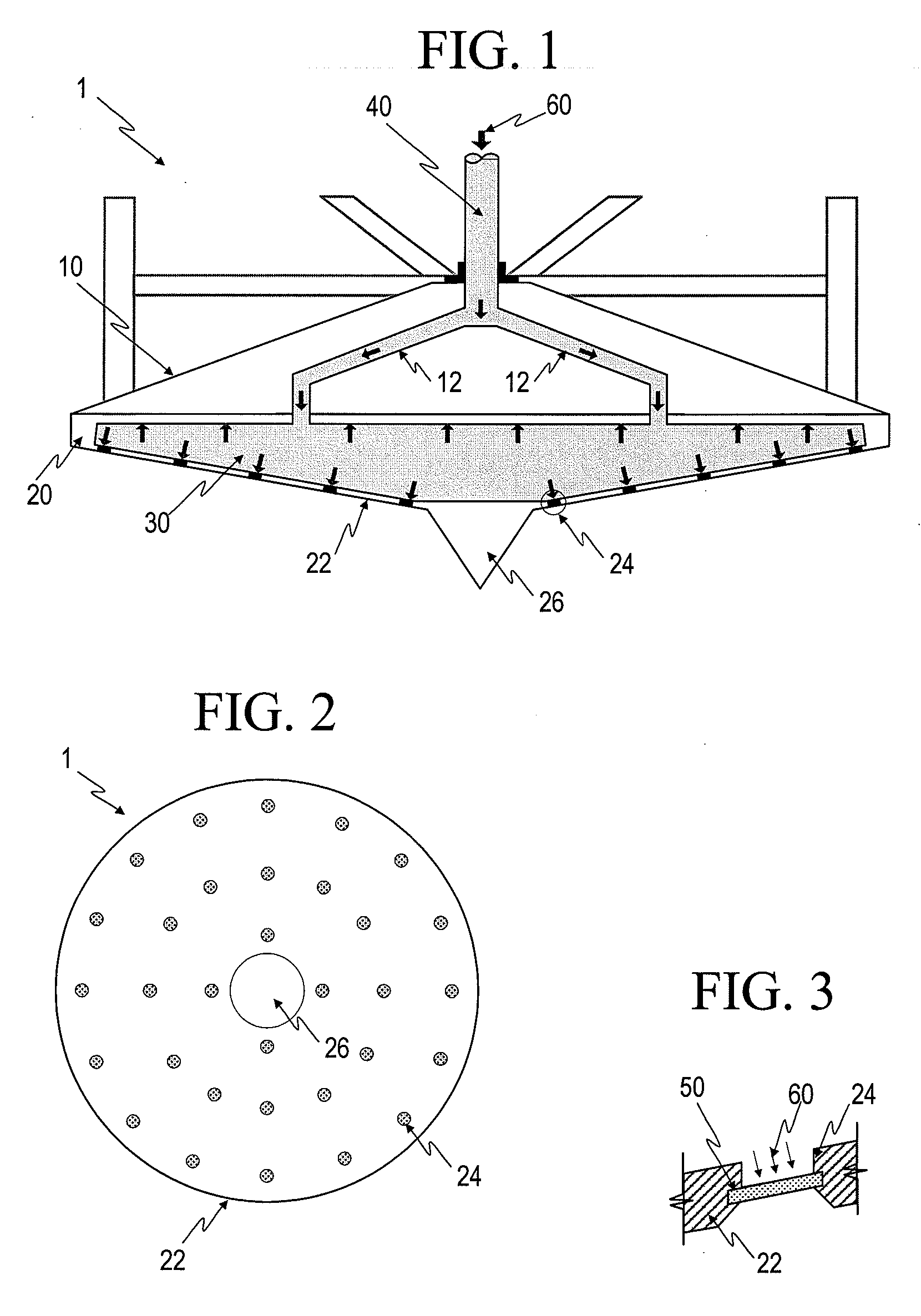

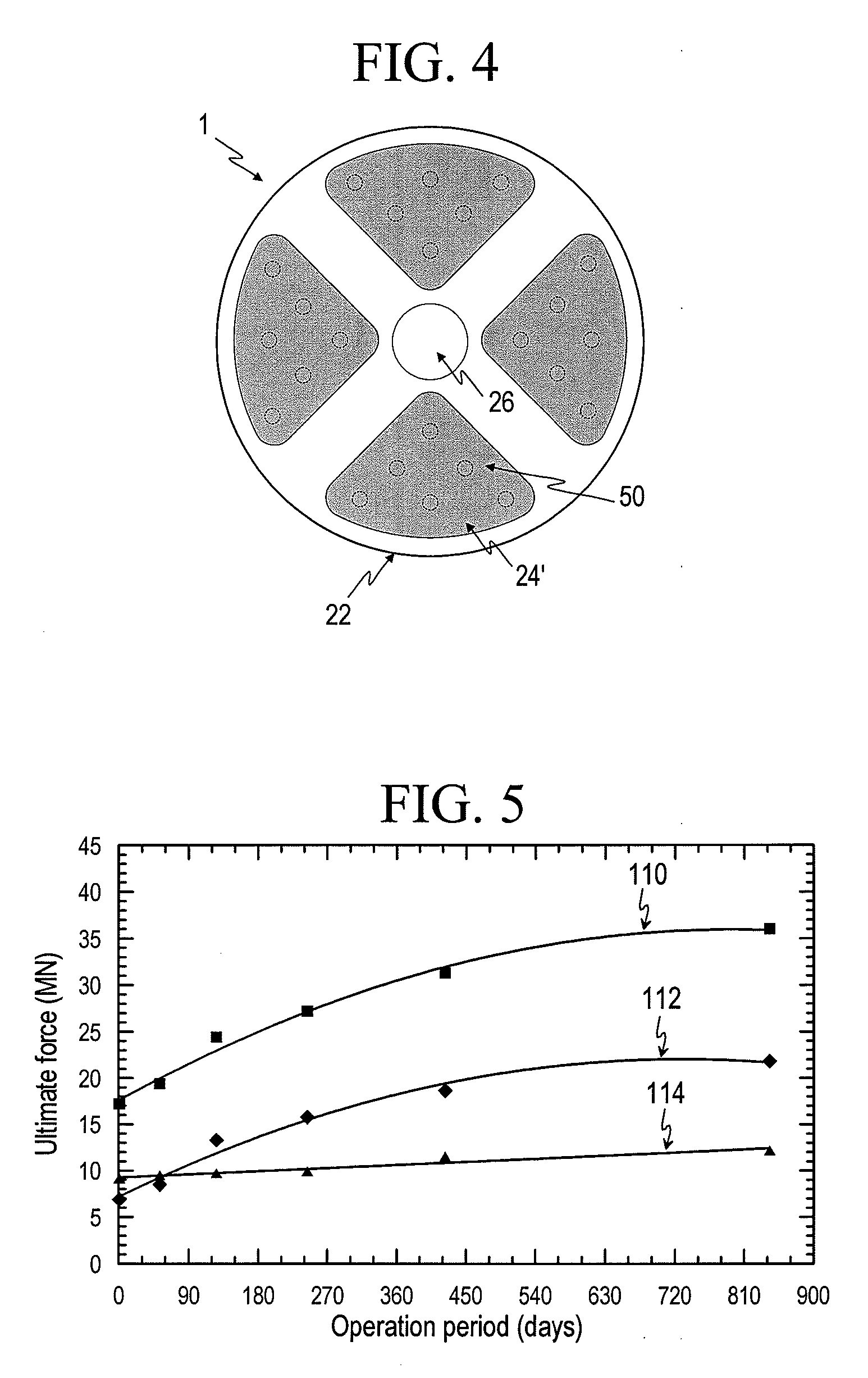

[0020] The present invention provides a foundation for an offshore platform that enables the extraction process to be performed effectively and efficiently. In one embodiment, the foundation 1 comprises an upper body 10 and a lower body 20, wherein the upper body 10 and lower body 20 have a frustum shape (see FIG. 1). It should be understood by one skilled in the art that the foundation 1 can take on other shapes. For instance, a caisson is contemplated. The base 22 of the lower body 20, which also refers to as the base 22 of the foundation 1, comprises a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com