Device for non-dissipative measurement of the current in an inductor

a current measurement and inductor technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of affecting the overall efficiency of the converter, affecting the accuracy of the measurement, and the current measurement which is obtained exhibiting an error related to the temperature, so as to improve the operation of the device and increase the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

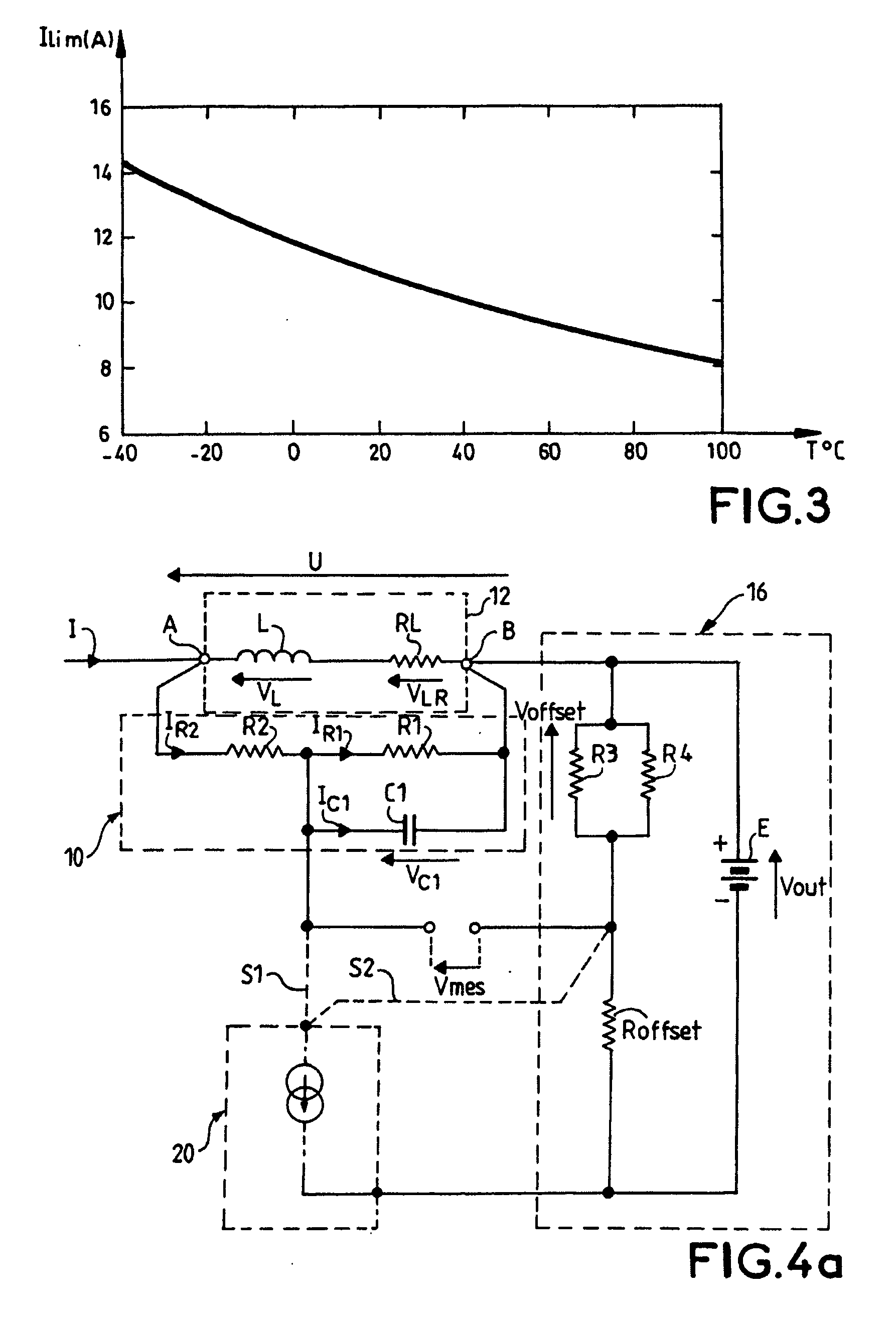

[0051] The diagram of FIG. 4a shows a device for measuring current in an inductor in a general case of the invention with a voltage offset.

[0052]FIG. 4a shows: [0053] the inductor 12 represented by its equivalent diagram comprising a pure reactive part L, in series with a resistor RL; [0054] a device for measuring current in the inductor 12, according to the invention, connected in parallel with the inductor comprising the two terminals A and B.

[0055] The device of FIG. 4a comprises: [0056] the network 10 as represented in FIG. 2 (or the measurement device of the state of the art of FIG. 1) in parallel with the inductor 12 and connected to the terminals A and B having the resistor R2 in series with the resistor R1 in parallel with the capacitor C1; [0057] a voltage offset circuit 16 having the generator E of DC voltage Vout connected in parallel with the offset resistor Roffset in series with the two resistors in parallel R3 and R4 and to the common point of the resistor R1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com