Exhauster for roaster

a technology for exhausting fans and roasters, which is applied in the direction of domestic stoves or ranges, heating types, lighting and heating apparatuses, etc. it can solve the problems of stationary tubes b, wall-mounted fans have a limitation to completely exhaust smoke and smell, and affect the interior appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] An exhauster for a roaster according to a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

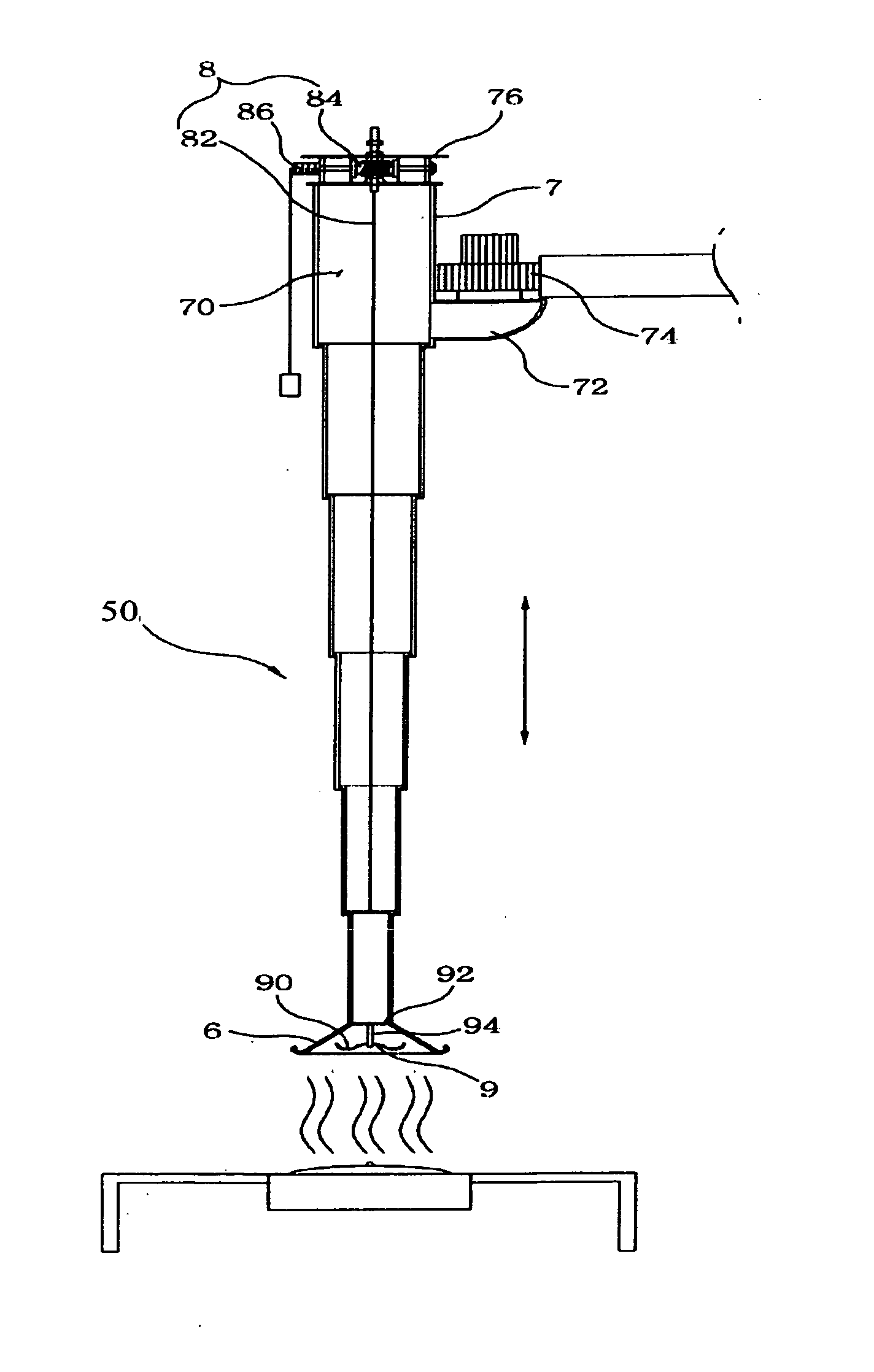

[0037]FIG. 3. is a side sectional view showing an overall configuration of an exhauster for a roaster according to the present invention. As shown in FIG. 3, the exhauster for a roaster according to the present invention includes a hood body 7 at the side of which a fan 74 is equipped, a hood tube 50 which is combined in the lower portion of the hood body 7, and an elevating apparatus 8 elevating the hood tube 50.

[0038] First, the hood tube 50 is a suction tube which inhales the smoke and smell generated through a roaster in which a plurality of pipes are telescopically combined so as to be folded in a multi-stage. A hood 6 having an extrinsic expansion section is connected at the lower end of the pipe positioned at the lowest bottom in order to collect the smoke and smell which are generated when burning the meat.

[0039] Here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com