Highly efficient isolated AC/DC power conversion technique

a conversion technique and high efficiency technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of increasing the complexity of the power converter, increasing the size and cost of the overall circuit, etc., to reduce the power requirements, reduce the circuit size and complexity, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

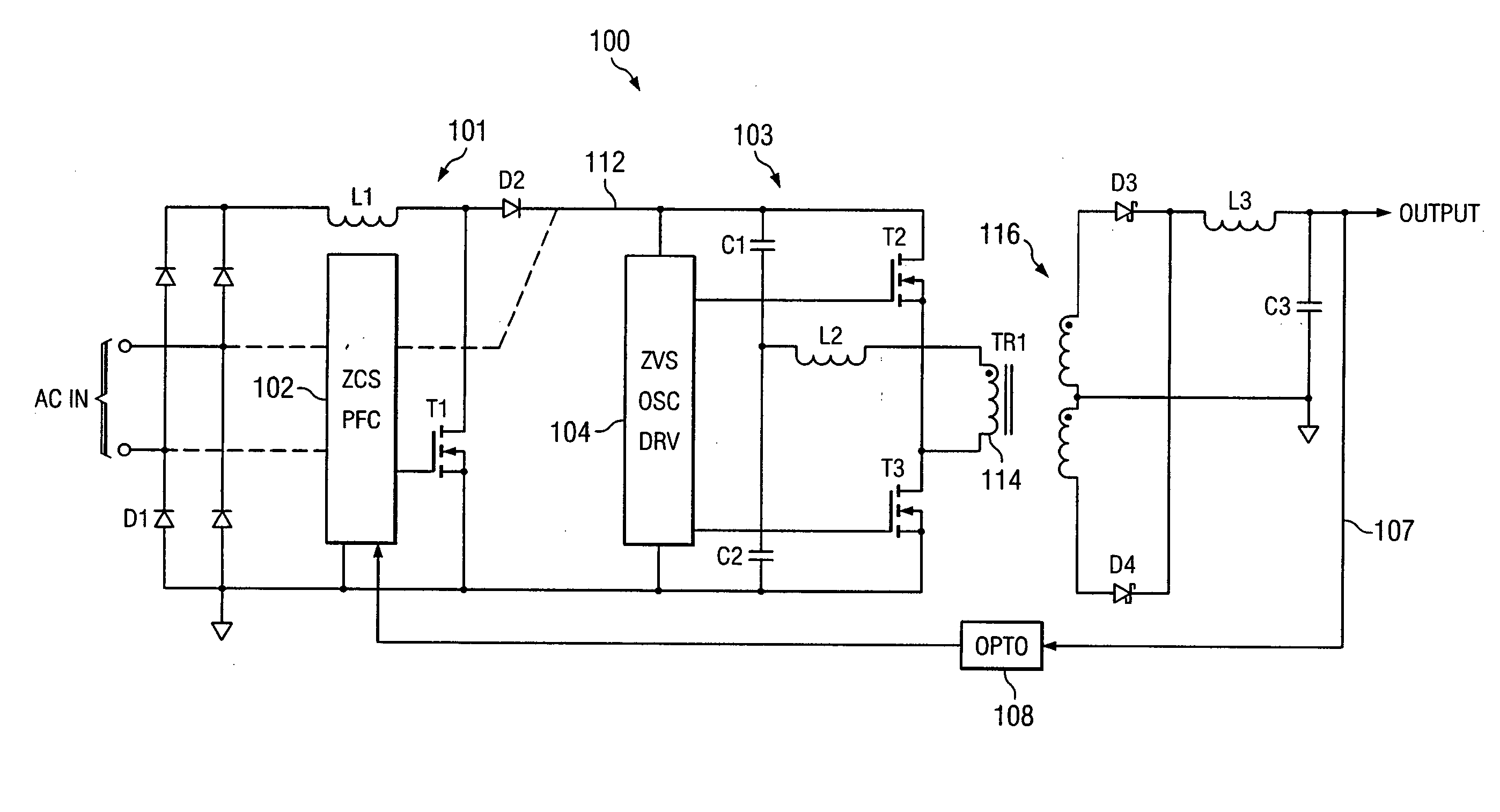

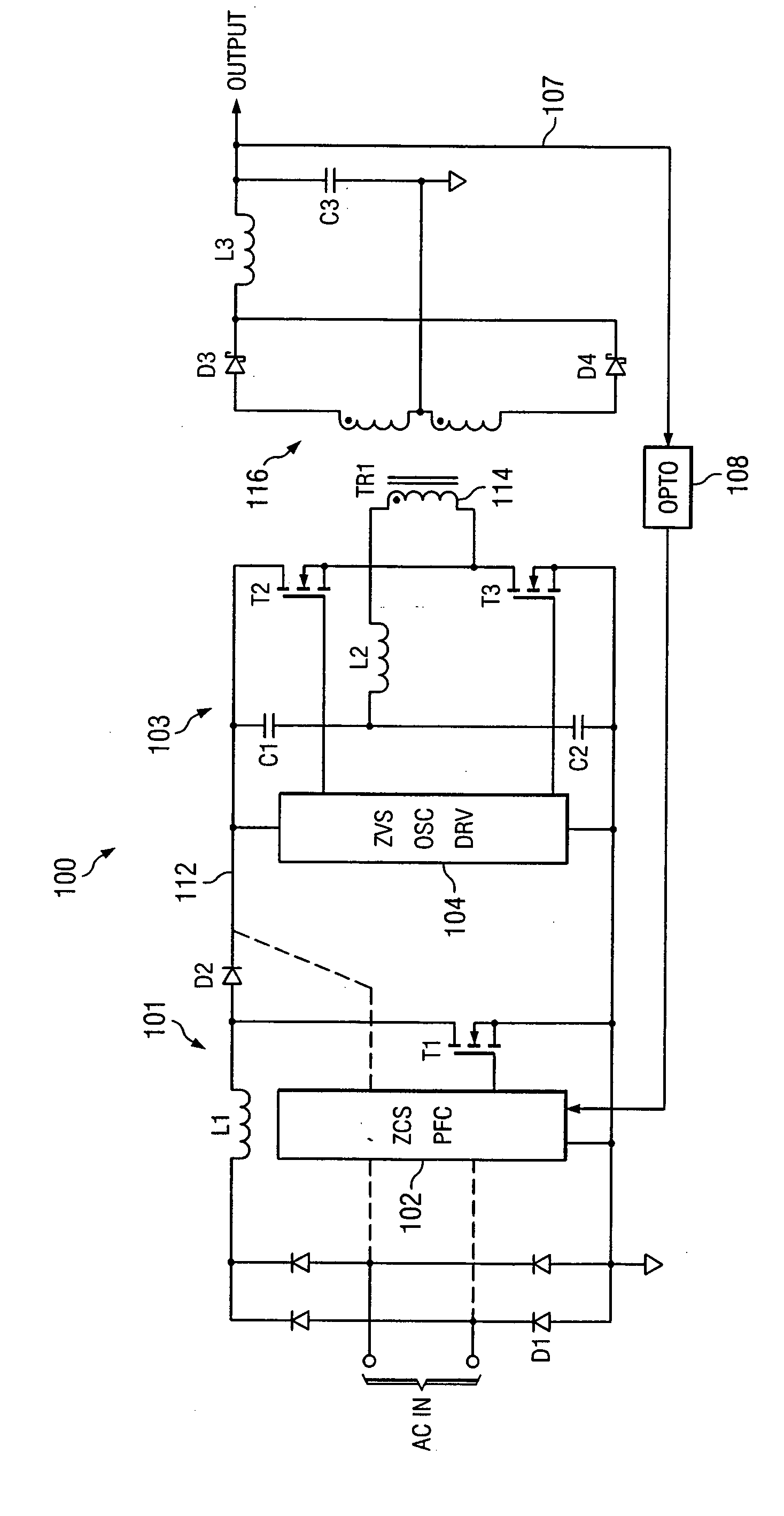

[0012] An AC-to-DC power converter is disclosed that can generate a regulated, isolated DC voltage output from a power factor corrected AC voltage input with improved efficiency. This highly efficient AC-to-DC power converter is a two-stage power converter that includes a zero current switched power factor correction front end followed by a zero voltage switched isolation converter for reducing the size, complexity, and power requirements of the overall circuit.

[0013]FIG. 1 depicts an illustrative embodiment of an AC-to-DC power converter 100, in accordance with the present invention. In the illustrated embodiment, the AC-to-DC power converter 100 is a two-stage power converter comprising a first power factor correction (PFC) stage 101, a second power conversion stage 103, an LC low pass filter including an inductor L3 and a capacitor C3, and a single feedback control loop 107 including an opto-coupler 108. The AC-to-DC power converter 100 is configured to receive an AC power input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com