Cellulose ester film, polarizing plate and display

a technology of cellulose ester film and polarizing plate, which is applied in the direction of polarizing elements, instruments, transportation and packaging, etc., can solve the problems of film rupture and other problems, and achieve the effect of reducing optical anisotropy and excellent visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0453] Charged into a glass flask equipped with a stirrer, two dripping funnels, a gas feeding tube, and a thermometer were 40 g of a mixture of Monomers Xa and Xb of the type and ratio described in Table 1, 2 g of mercaptopropionic acid as a chain transfer agent, and 30 g of toluene. The resulting mixture was heated to 90° C. Thereafter, the mixture of Monomers Xa and Xb of the type and ratio described in Table 1 was dripped over 3 hours from one dripping funnel, while 0.4 g of azobisisobutyronitrile dissolved in 14 g of toluene was simultaneously dripped from the other dripping funnel over 3 hours. Thereafter, 0.6 g of azobisisobutyronitrile, dissolved in 56 g of toluene, was dripped over 2 hours, and reaction was performed for an additional 2 hours, whereby Polymers X1—X5 were prepared. The weight average molecular weight of each of above Polymers X1—X5, as shown in Table 1, was determined employing the method described below. The polymers having different molecular weights were ...

example 2

[0486] By employing each of Cellulose Ester Films 1-39, 39 polarizing plates were prepared. Subsequently, the degradation of the polarizer, the dimensional stability of the polarizing plate, and the curling of the polarizing plate were evaluated.

[0487] A 120 μm thick polyvinyl alcohol film was immersed into 100 kg of an aqueous solution incorporating 1 kg of iodine and 4 kg of boric acid, and then stretched at a factor of 6, whereby a 25 μm thick polarizer was prepared. One side of the resulting polarizer was allowed to adhere to each of above Cellulose Ester Films 1-39 which had been subjected to alkali saponification, employing, as an adhesive, a 5% aqueous solution of completely saponified type polyvinyl alcohol.

[0488] The other side of each film was allowed to adhere to an antireflection film incorporating the hard coat layer described below, whereby Polarizing Plates 1-39 were prepared.

Saponification Process2N—NaOH50° C.90 secondsWashing Processwater30° C.45 secondsNeutrali...

example 3

[0524] A Polarizing plate was prepared in the same manner as Example 2, except that the polarizer employed in Polarizing Plates 1-39 was replaced with the ethylene-modified PVA film, and evaluated in the same manner as Example 2. The polarizing plate of the present invention reproduced Example 2 and rupture problems during preparation of the polarizing plate was minimized and visibility was excellent. In addition, curling characteristics of the following polarizing plates was evaluated to B-A.

[0525] Impregnated into 100 parts by weight of ethylene-modified PVA at a content of ethylene units of 2.5 mol %, a saponification ratio of 99.95 mol %, and a degree of polymerization of 2,400 were 10 parts by weight of glycerin and 170 parts by weight of water. The resulting mixture was melt-kneaded, degassed, melt-extruded onto a metal roller via a T die, and then cast. The thickness of the ethylene-modified PVA film, after drying and a heat treatment, was 40 μm and the average value of hot ...

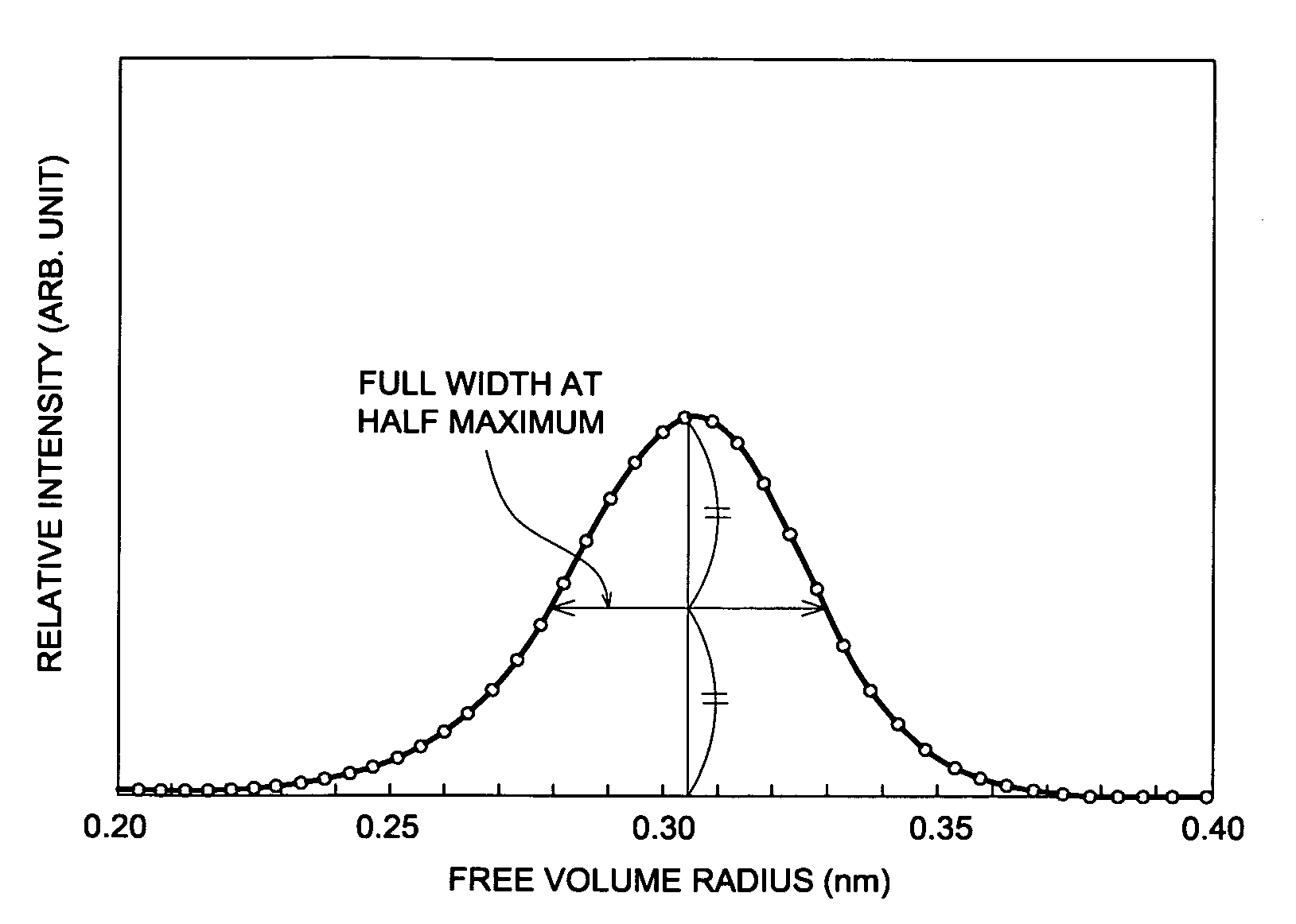

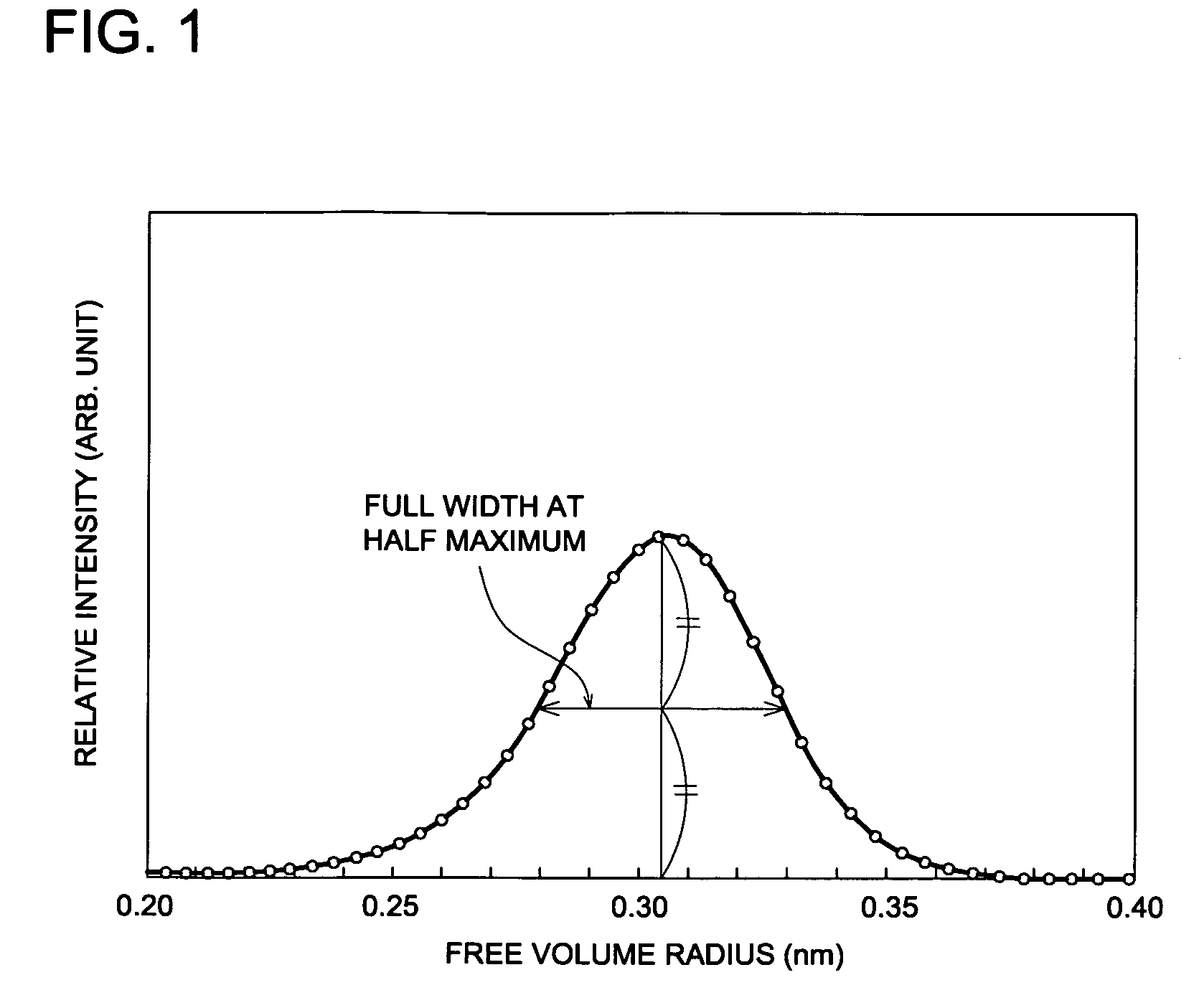

PUM

| Property | Measurement | Unit |

|---|---|---|

| half-width | aaaaa | aaaaa |

| half-width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com