Vent cap assembly

a technology of vent system and vent cap, which is applied in the direction of gaseous heating fuel, heating types, stoves or ranges, etc., can solve the problems of insufficient weather compensation, water damage, extinguishing of combustion flames in heating appliances, etc., to reduce the flow, improve the fluid flow, and minimize the reverse flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

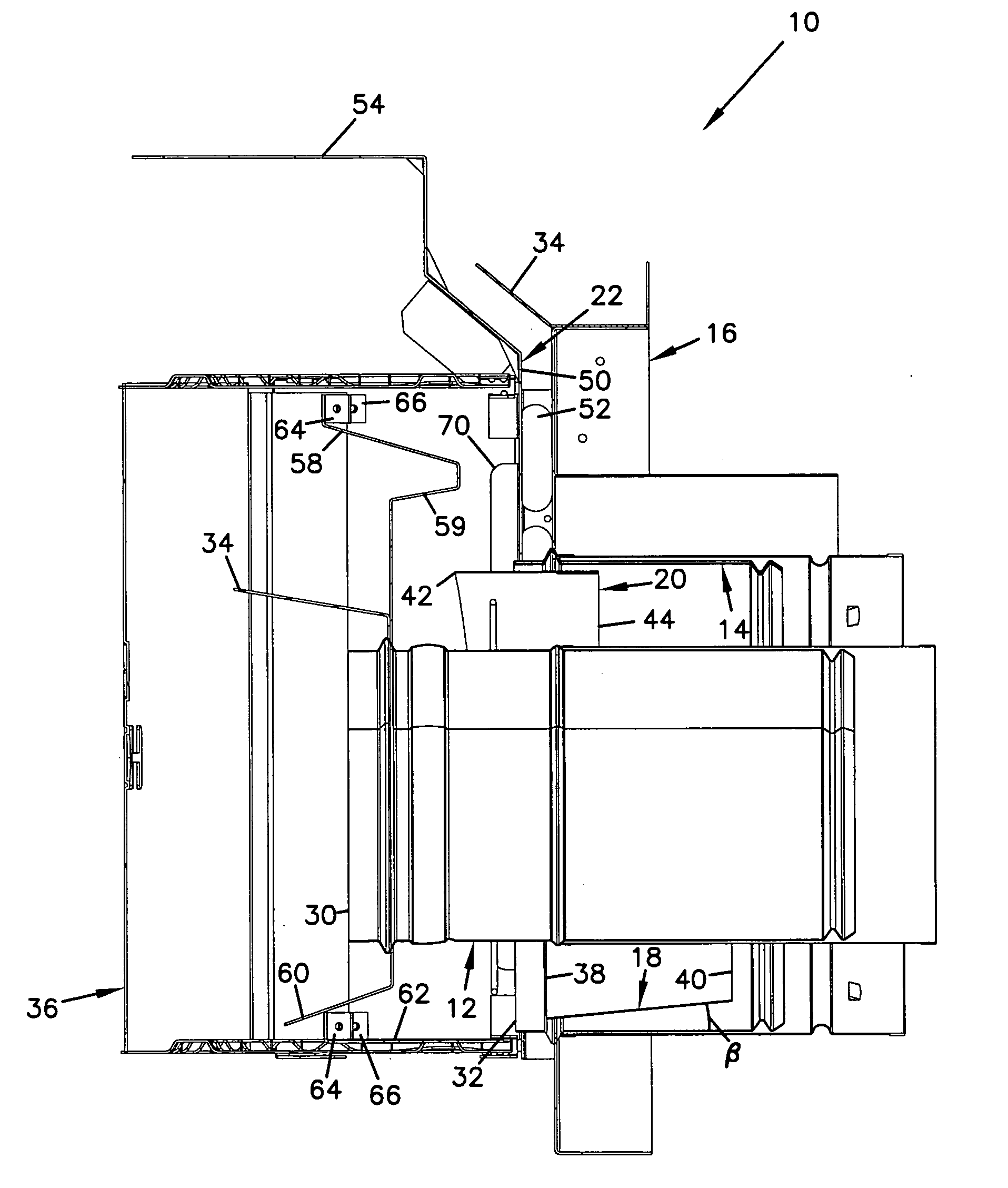

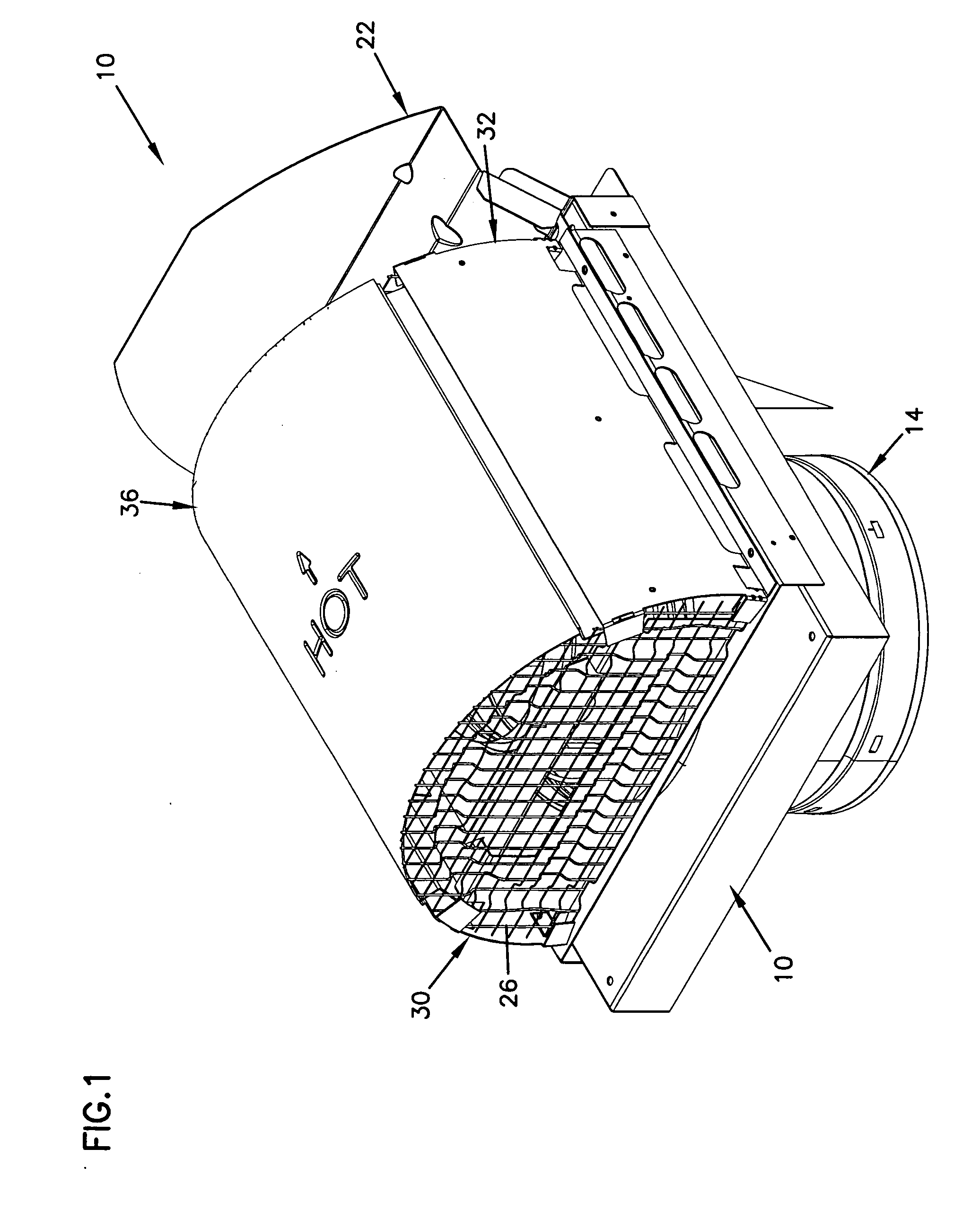

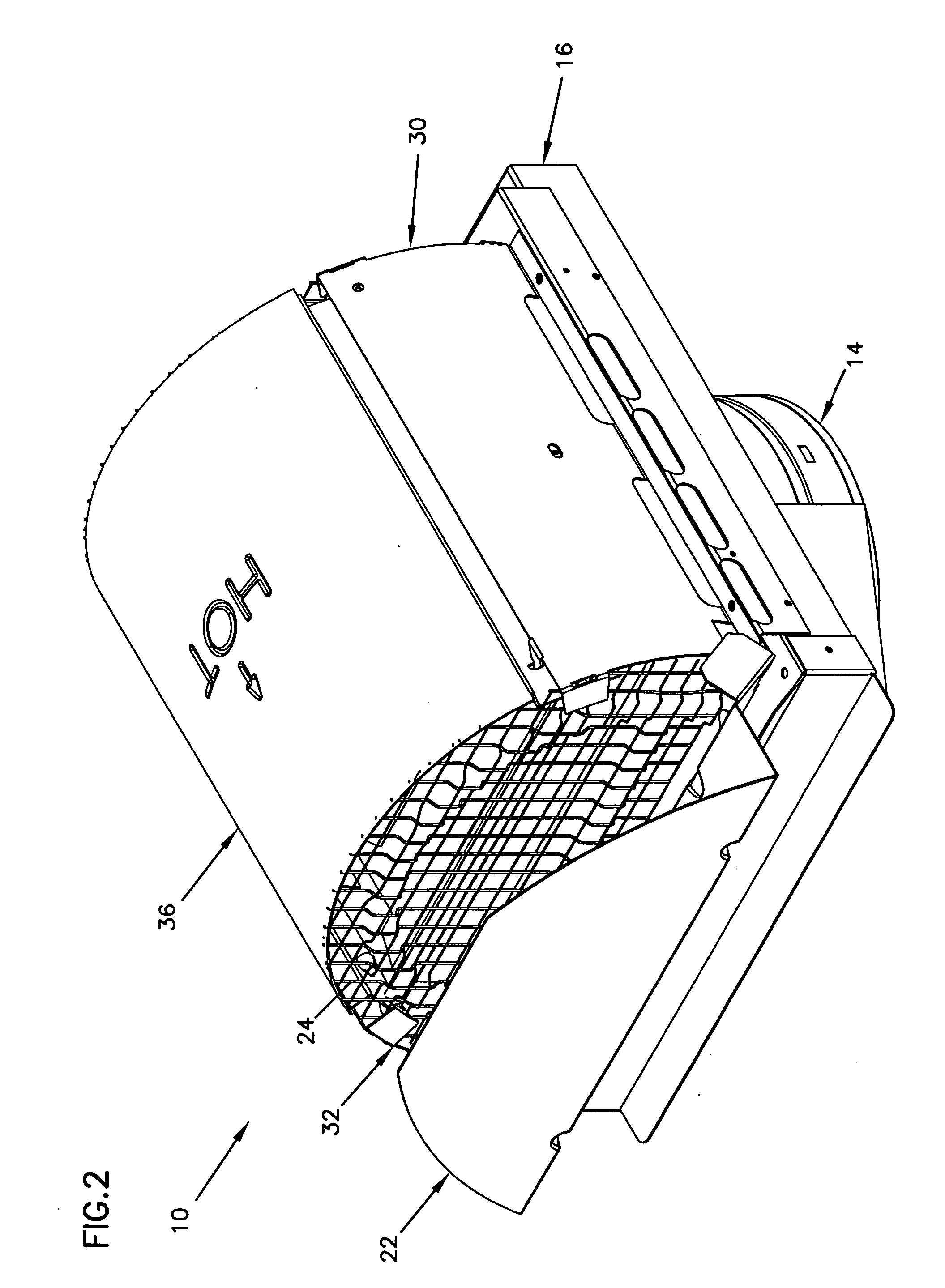

[0024] The present invention generally relates to vents, vent covers, vent caps, and vent assemblies. Example embodiments described herein are directed to vent systems and structures that provide improved performance in various weather conditions. The example systems include an exhaust member configured to deliver exhaust fluids from a heating appliance, and an intake member configured to deliver intake air to the heating appliance. The exhaust and intake members are preferably coaxially oriented with the exhaust member extending within the intake member. This coaxial arrangement (sometimes referred to as a B-vent arrangement) may provide cooling of the exhaust gases in the exhaust member by cooling the exhaust member with the intake fluids flowing through the intake member. Other embodiments may include other arrangements of the exhaust and intake members relative to each other.

[0025] One aspect of the invention relates to a vent assembly that includes an intake duct having an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com