Heating and cooling system for biological materials

a biological material and cooling system technology, applied in the field of biological materials, can solve the problems of less uniformity of active materials, increased difficulty in reducing temperature, and degradation of active materials, so as to reduce the thickness of ice formed, reduce the compartmentalization of medium, and minimize the effect of ice formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-3

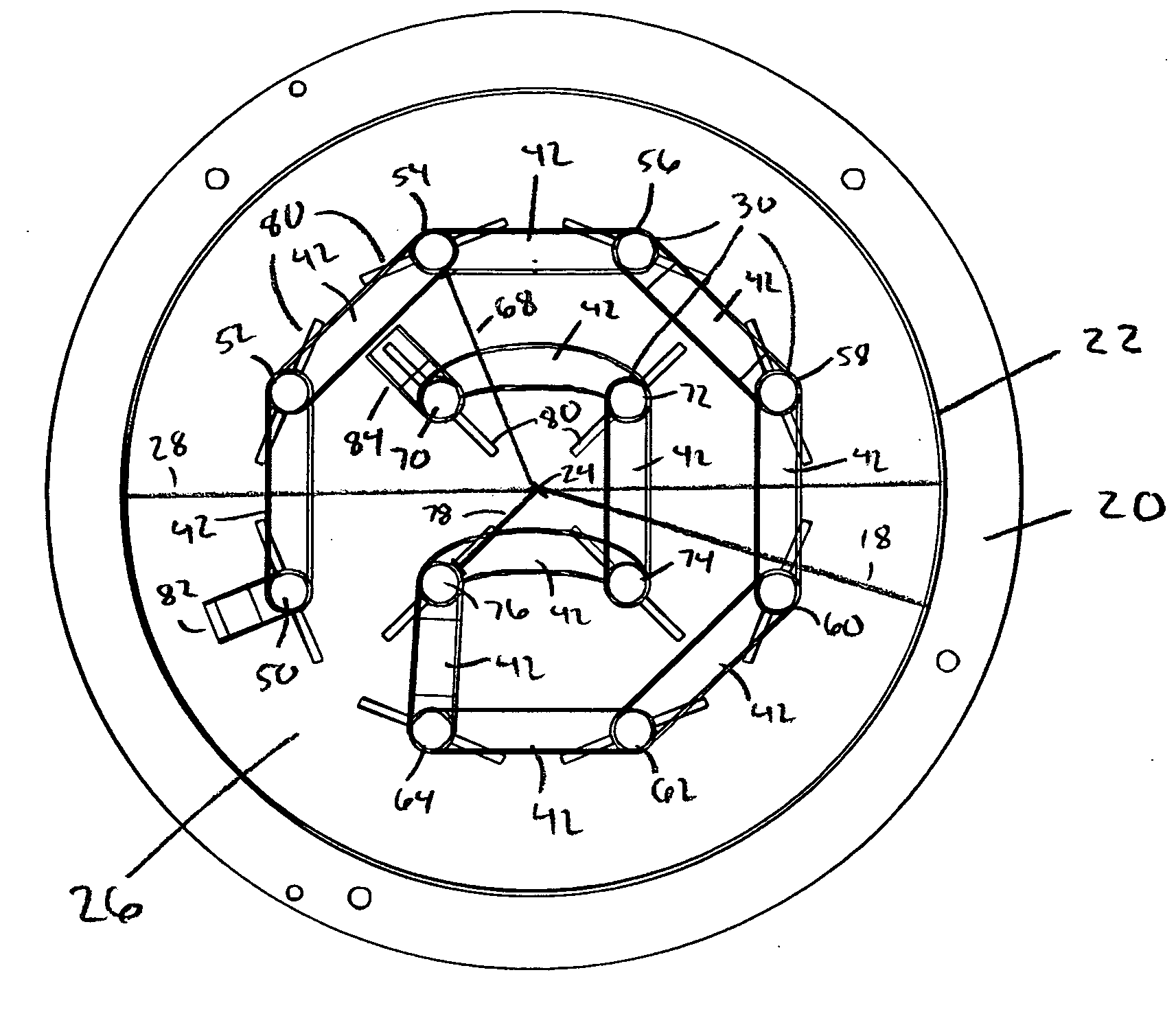

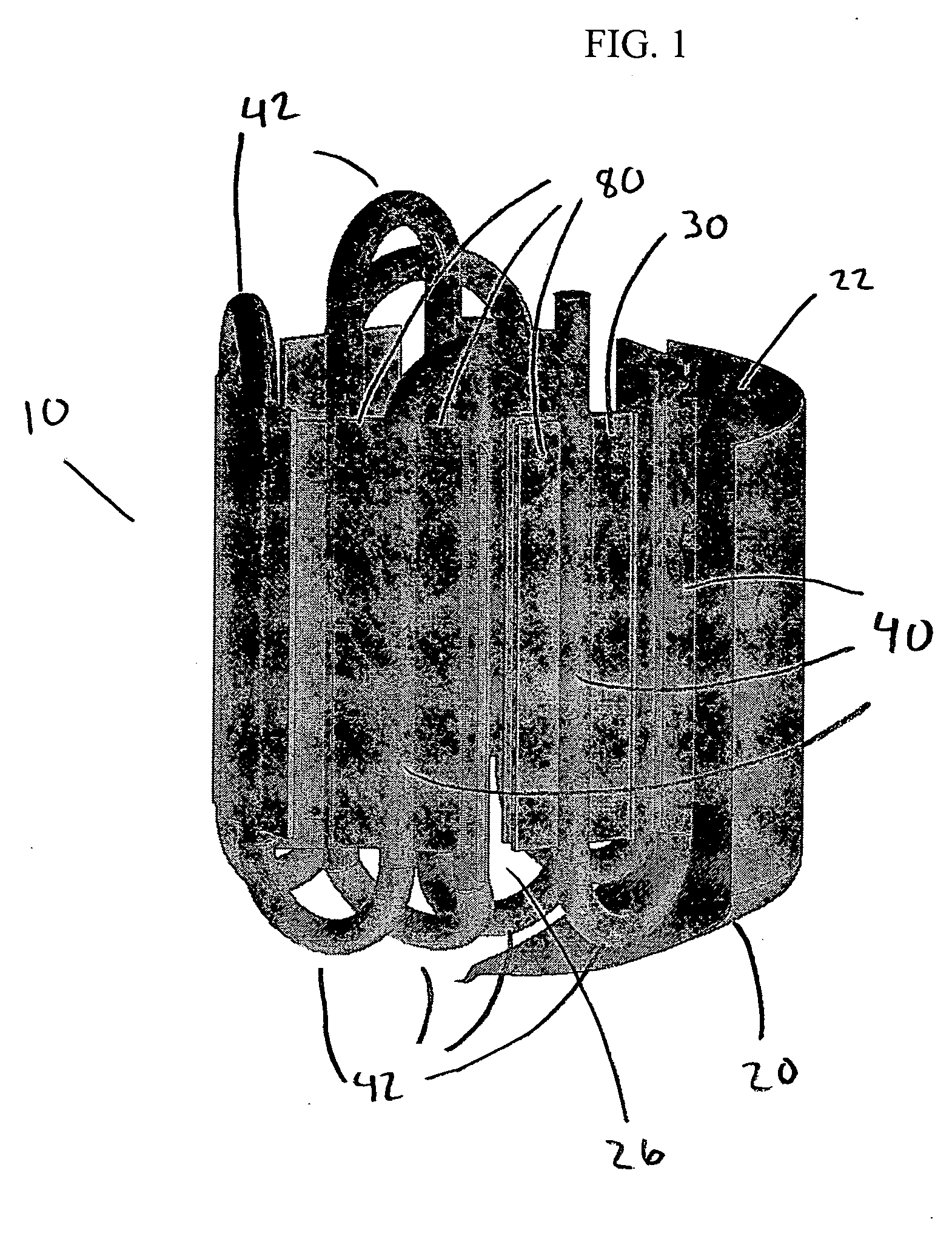

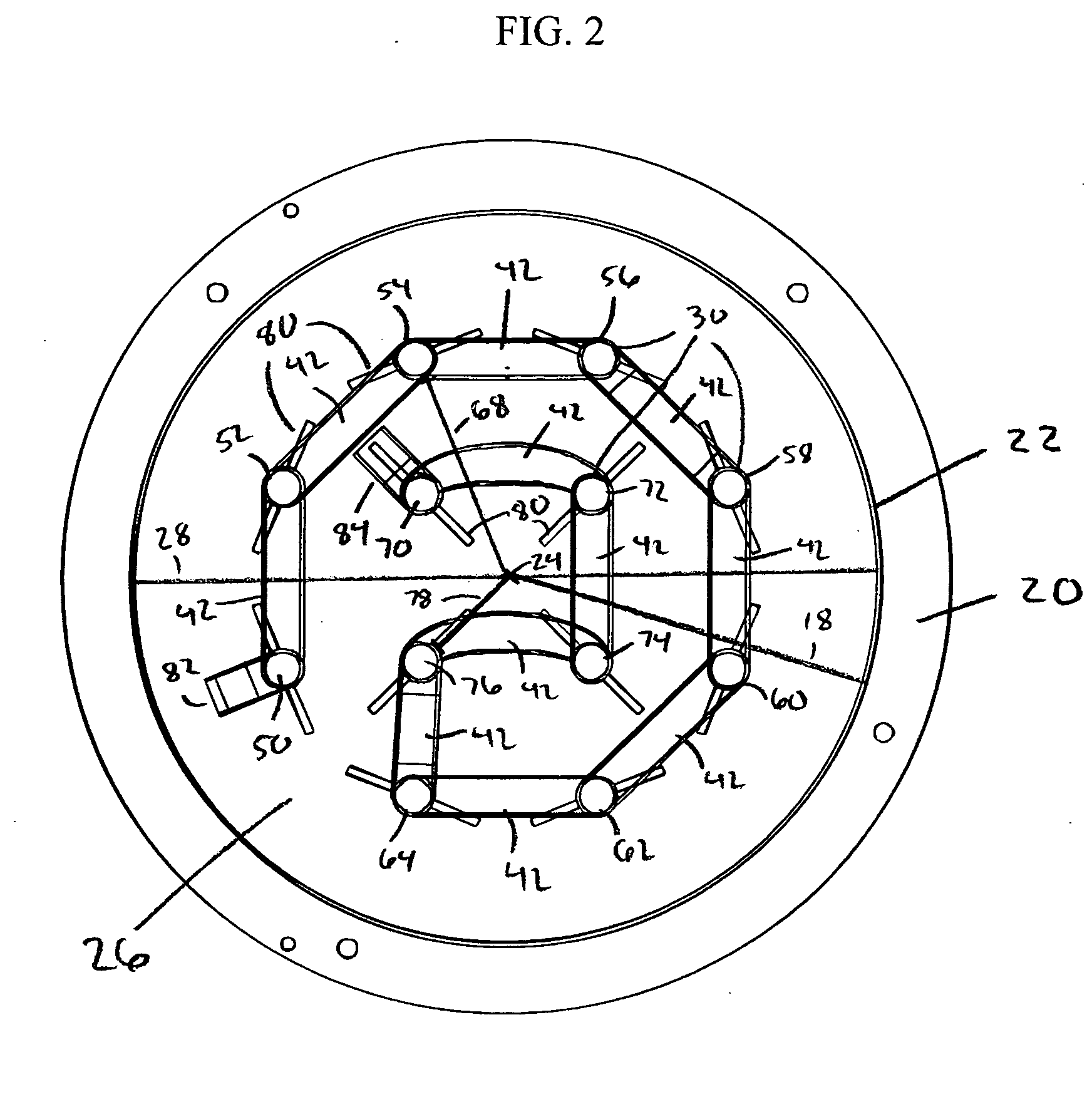

[0048] The cooling characteristics of several heating / cooling systems designs were analyzed using computer simulations with FLUENT™ computational fluid dynamics software. The simulations were based on a nominal 300 L capacity, 34″ inside diameter vessel called the 300 L Cryovessel available from Integrated Biosystems. The inner wall and heat transfer surface temperature were set at −30° C. The temperature profile of a fluid being cooled was modeled as a function of time. Three systems were modeled: 1) the prior art Integrated Biosystems design (Comparative Example 1); 2) the finned design of the present invention shown in FIGS. 1-3 (Inventive Example 2); and 3) the finless design of the present invention shown in FIGS. 4-5 (Inventive Example 3).

##ventive example 2

INVENTIVE EXAMPLE 2

[0050]FIG. 8 shows the temperature profile of the fluid for the finned design after cooling for approximately 6.5 hours. It can be seen that the present invention provides relatively small pockets of uncooled material between the heat transfer surfaces.

##ventive example 3

INVENTIVE EXAMPLE 3

[0051]FIG. 9 shows the temperature profile of the fluid for the finless design after cooling for approximately 6.5 hours. It can be seen that the present invention provides small pockets of uncooled material between the conduit portions.

[0052] In comparing the performance of the three systems, it can be seen that the prior art design leaves large pockets of uncooled fluid, and that the present invention provides much smaller pockets of uncooled fluid. It can be seen that the two embodiments of the present invention have better temperature distribution than the prior art design. Although the finless design did not perform as well as the finned design, it still showed superior cooling to the prior art design. The prior art design has large areas that cool slowly due to the distance from the heat transfer surfaces.

[0053] The computer simulations were also used to determine the liquid fraction remaining in the vessel as a function of time, to determine how quickly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com