Metal tank with a synthetic resin sheet, and unit panel

a technology of synthetic resin and metal tanks, which is applied in the field of metal tanks with synthetic resin sheets and unit panels, can solve the problems of high cost of materials for tanks, incompetence in costing, and crack production, and achieve the effects of reducing production costs, good workability, and excellent durability and waterproof properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0050]FIG. 7 is a perspective view showing a unit panel with a synthetic resin sheet, to which an engagement member is attached, according to the present invention, and FIG. 8 is a cross-sectional view of FIG. 7 taken along line -.

[0051] Referring to FIGS. 7 and 8, the unit panel 500 of the present invention comprises an upper plate 510, a side plate 520 formed by vertically bending the rectangular surface of the upper plate 510, and a plurality of engaging members 550 provided to pass through the upper plate 510.

[0052] The upper plate 510 is formed with a recess, center of which is formed to be depressed in the downward direction, and an engaging member 550 is provided at the corners thereof.

[0053] The side plate 520 is formed with a plurality of engagement holes 532 in the longitudinal direction.

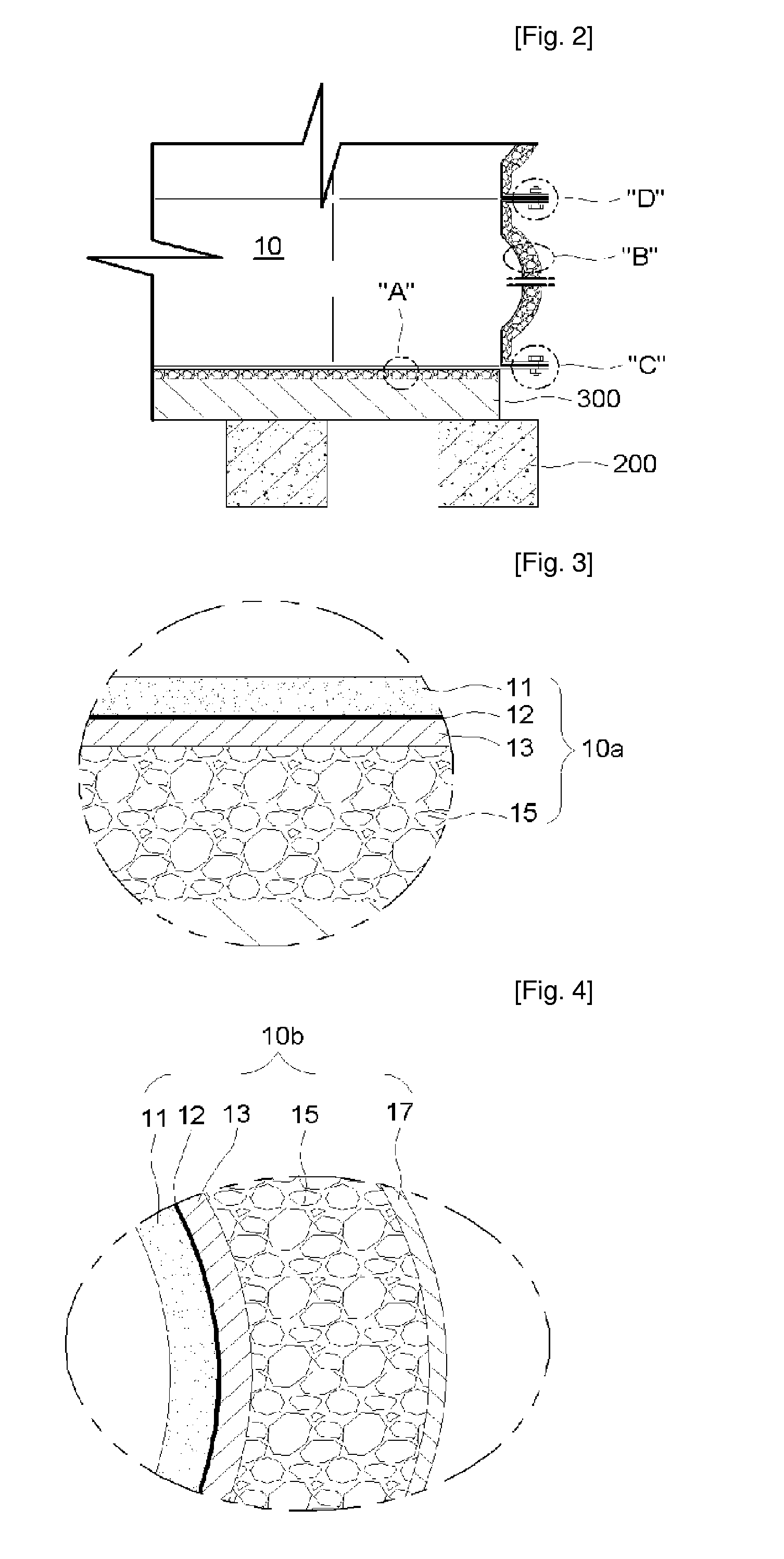

[0054] Now, referring to the structure of the unit panel 500 of the present invention, it is constructed that the synthetic resin sheet 561, the thermal insulation material 563, and the...

first embodiment

[0057] In the present invention, it is possible to minimize the waste of the materials to thereby reduce the production cost, because it is not required in the unit panel 500 to provide the first metal plate 13 stacked between the synthetic resin sheet 11 and the thermal insulation material 15 of the present invention due to the provision of the engagement member 550.

[0058] The engagement member 550 is inserted and engaged into a through-hole (not shown) in the second metal plate 565 of the unit panel 550 of the present invention, or it is formed integrally with the plate by welding an outer peripheral edge of the engagement member inserted into the through-hole.

[0059] The upper surface of the engagement member 550 of the present invention is hermetically sealed the foamed synthetic resin sheet. This is because separate water proof material is required, if the upper surface and the lower surface are of a completely opened penetrating structure, to accomplish the water proof at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com