PU sole for shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

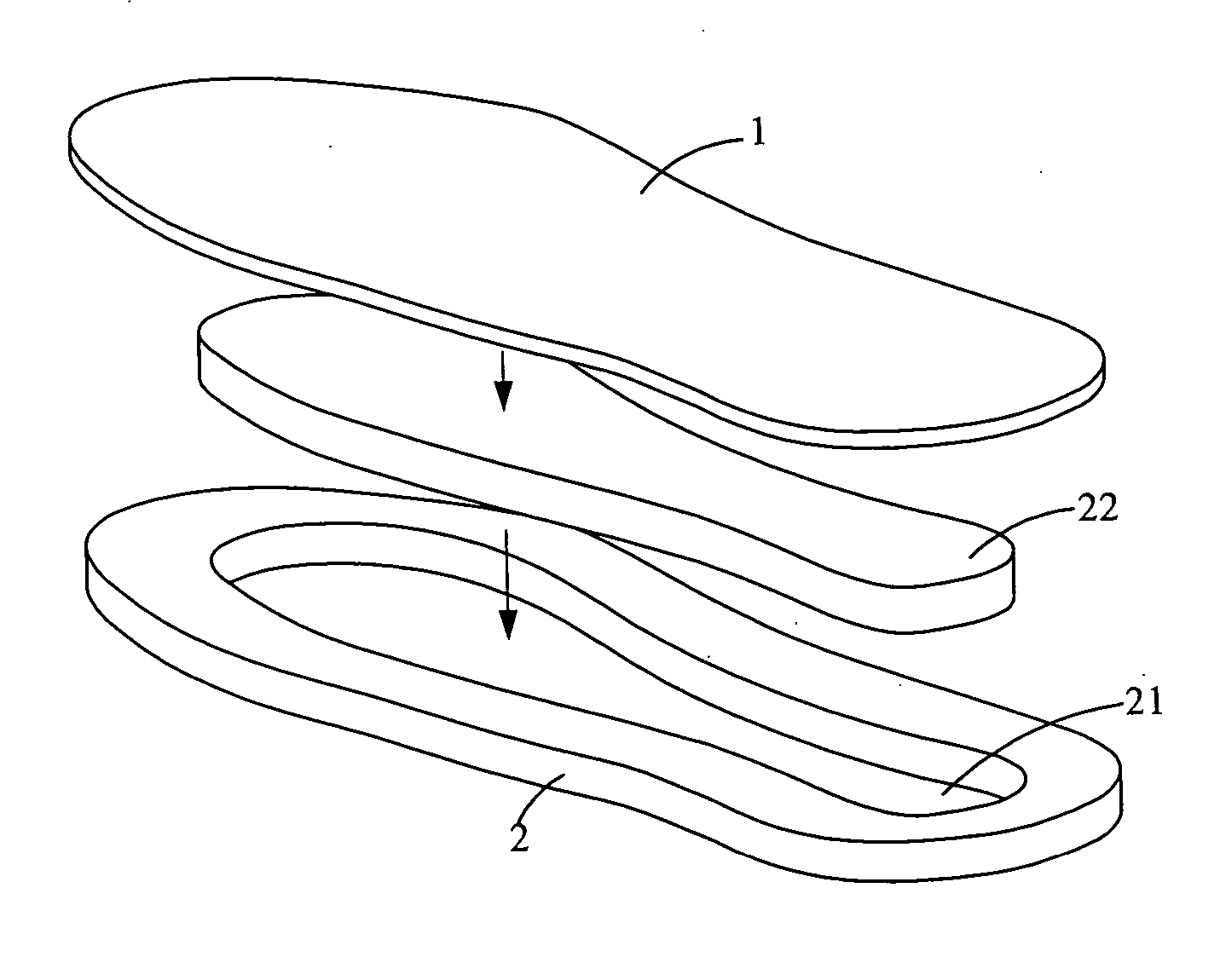

Image

Examples

second embodiment

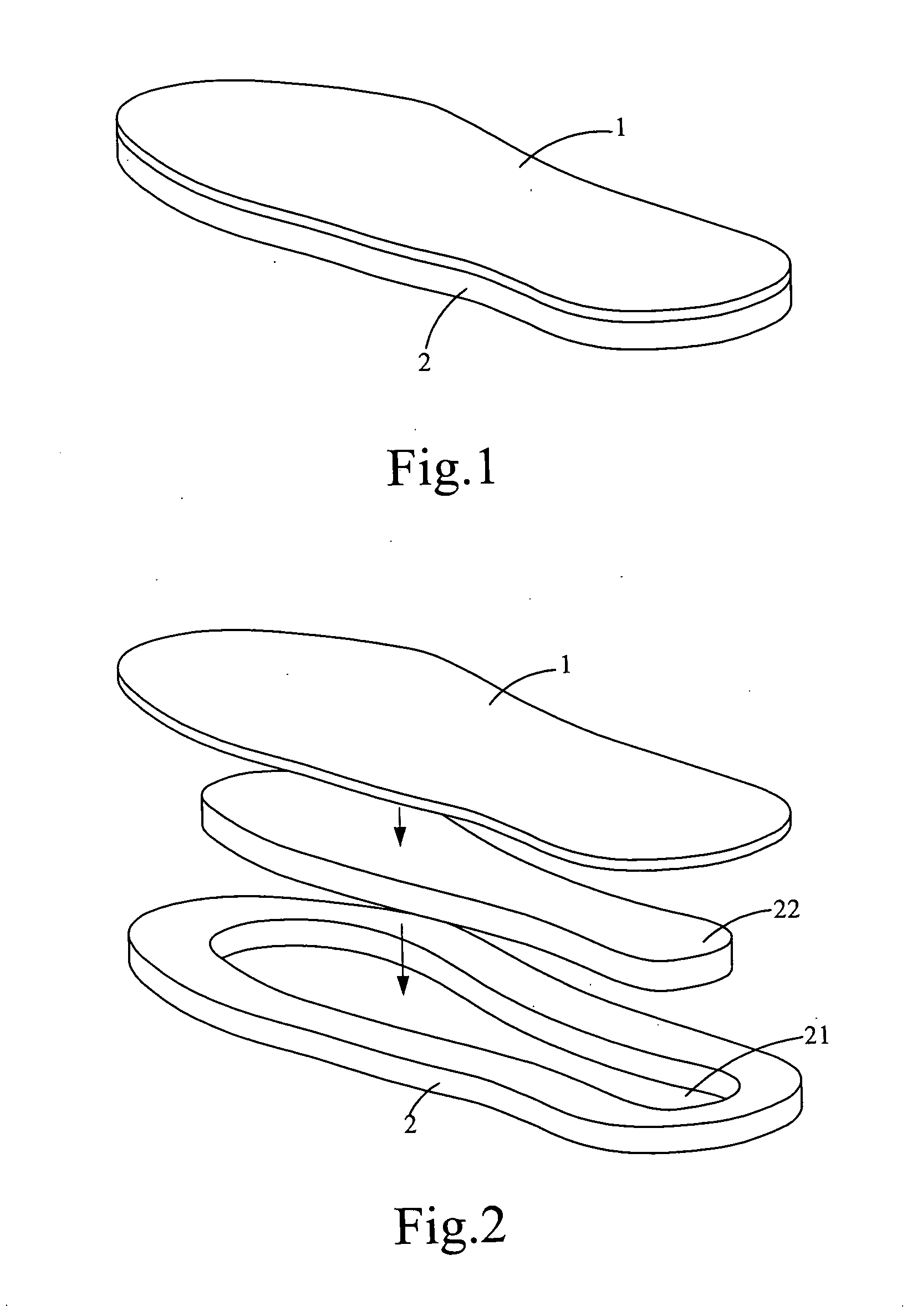

[0017] Referring to FIG. 3, the present invention is illustrated, as shown, the present invention can be applied to kinds of all sizes and styles of shoes.

third embodiment

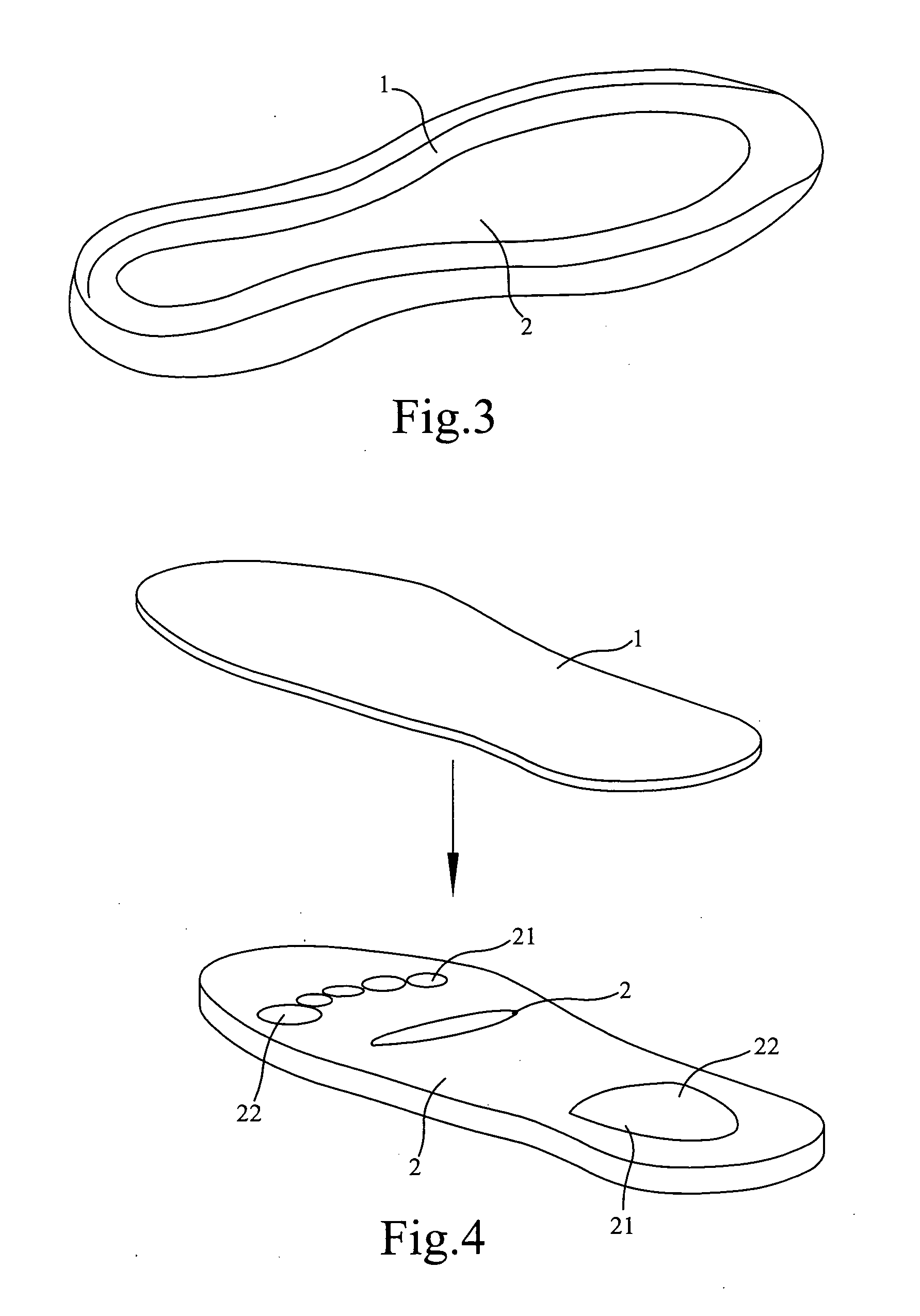

[0018] Referring to FIG. 4, based on the prior embodiments, the present invention is illustrated as shown. A number of improved air permeable shaped holes 21 are illustrated as shown. In that, holes 21 are formed through the base layer 2. Theses holes 21 are placed below the sole and heel of a man's foot. And these air permeable portions are formed through and filled in these shaped holes 21. Adoption of this kind of structure further saves more material cost for manufacturing shoe soles. And improves the products' competitive ability in market promotion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com