Pneumatic tool with as-cast air signal passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

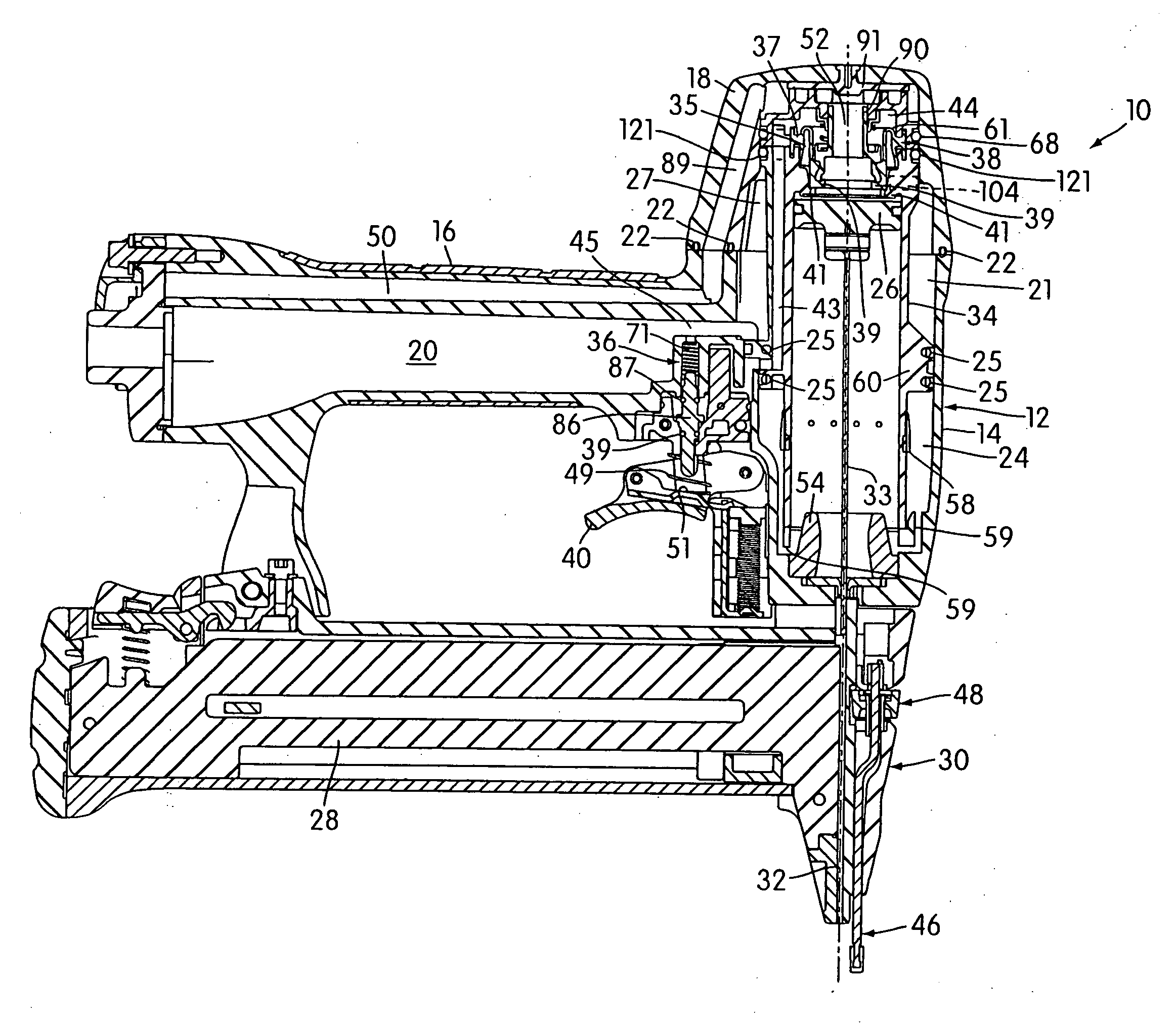

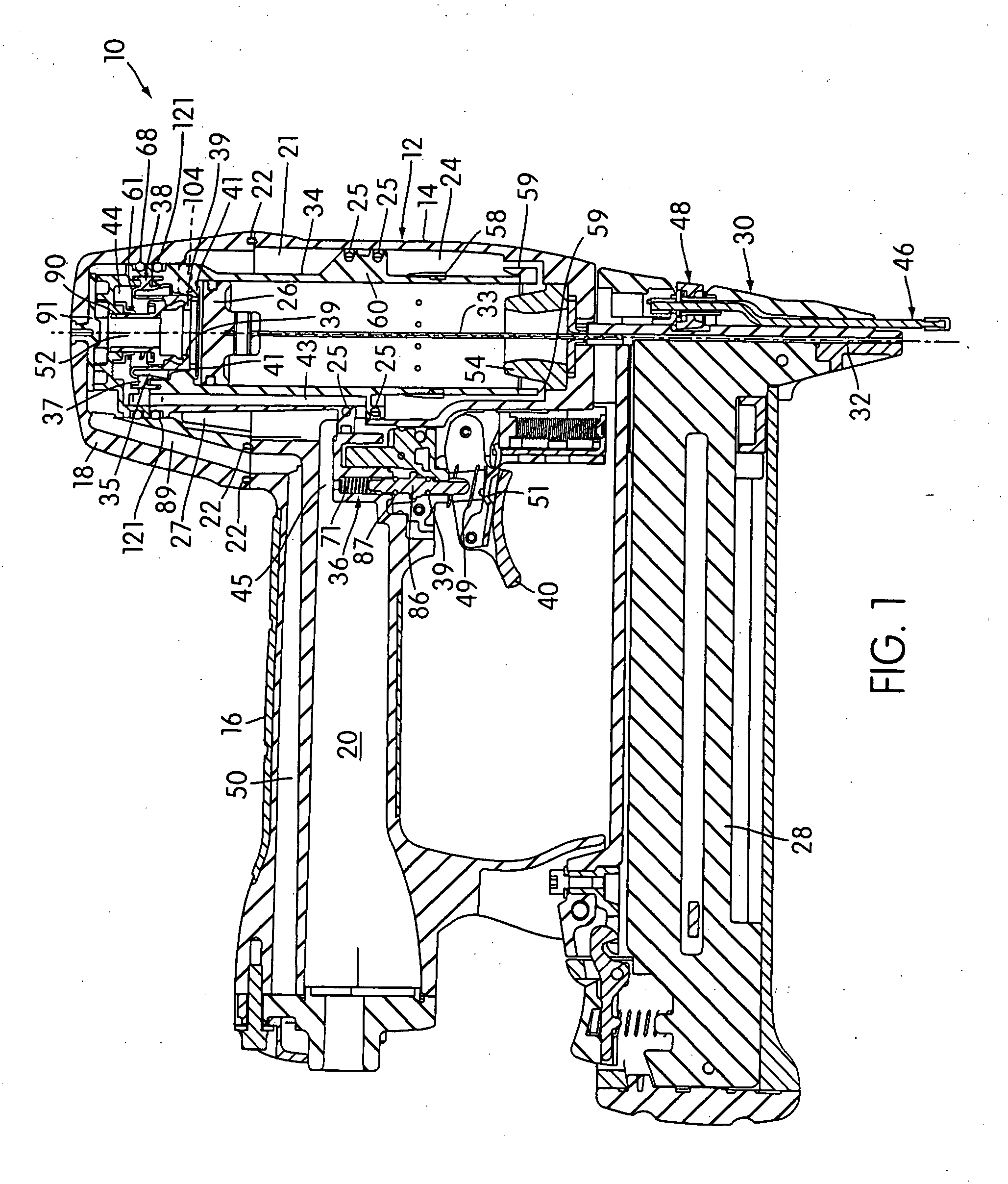

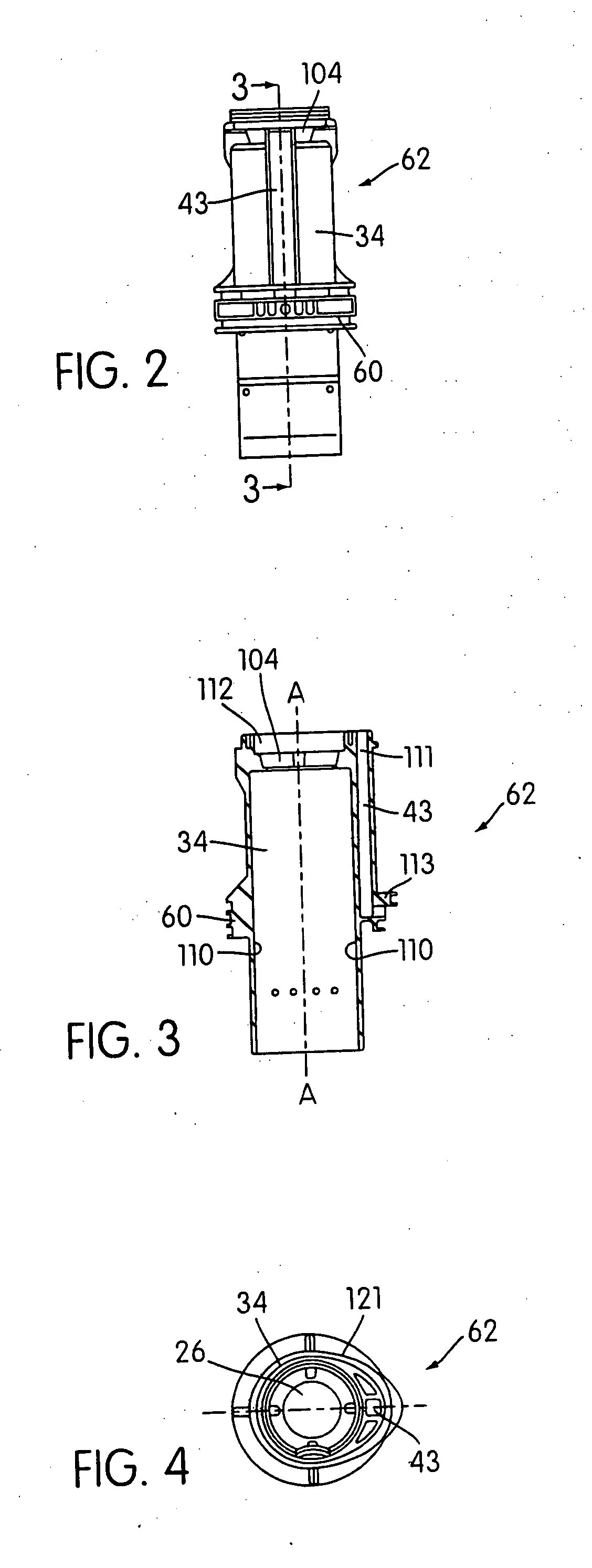

[0018] Referring now to the drawings, more particularly referring to FIG. 1, there is shown therein a fastener driving device, generally indicated at 10, which embodies the principles of the present invention. The operation of device 10 is explained more fully in U.S. Application No. 60 / 369,884, which is hereby incorporated by reference. The tool comprises housing 12 having, among other things, a cylinder containing body portion 14, a handle portion 16 and a cap portion 18. The size and shape of these components can vary considerably depending on the type of fastener and application, but all have in common an internal air chamber 20 for containing compressed air, for example, from an external source.

[0019] The compressed air chamber 20 is pressurized from an air supply line through an inlet connection attached to the handle (not shown). In this particular embodiment, the cap 18 may be attached to the body portion 14 with screws (not shown). Part of the volume in cap 18 is used to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com