Concrete forms

a concrete and footing technology, applied in the field of concrete footings and forms, can solve the problems of difficult if not impossible use of wood forms, easy damage to materials commonly used for concrete forms, and inability to meet the needs of construction, etc., to achieve the effect of convenient storage, easy positioning, and light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Turning now to the drawings, the form sections and accessories will be described in preferred embodiments by reference to the numerals of the drawing figures wherein like numbers indicate like parts.

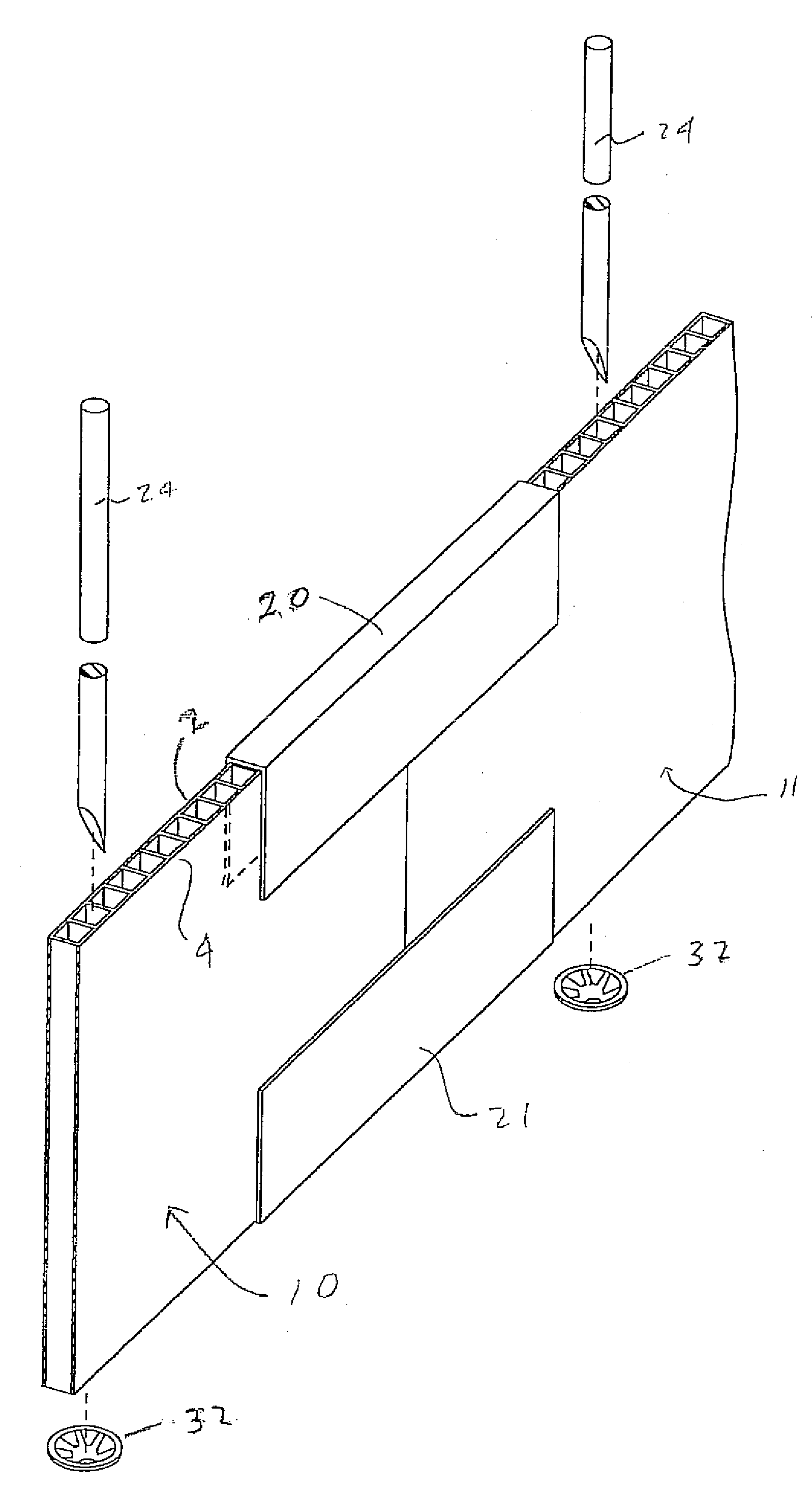

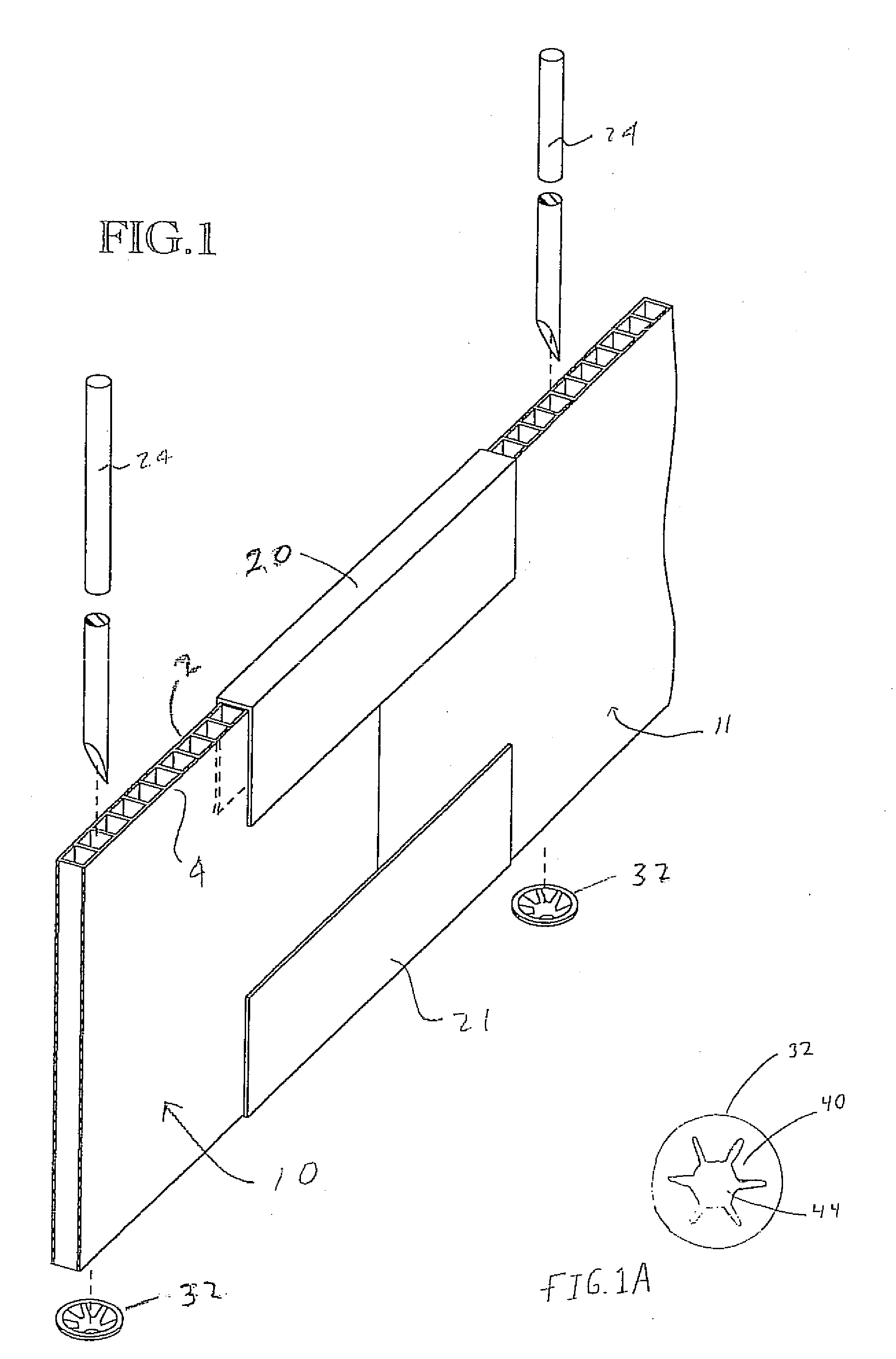

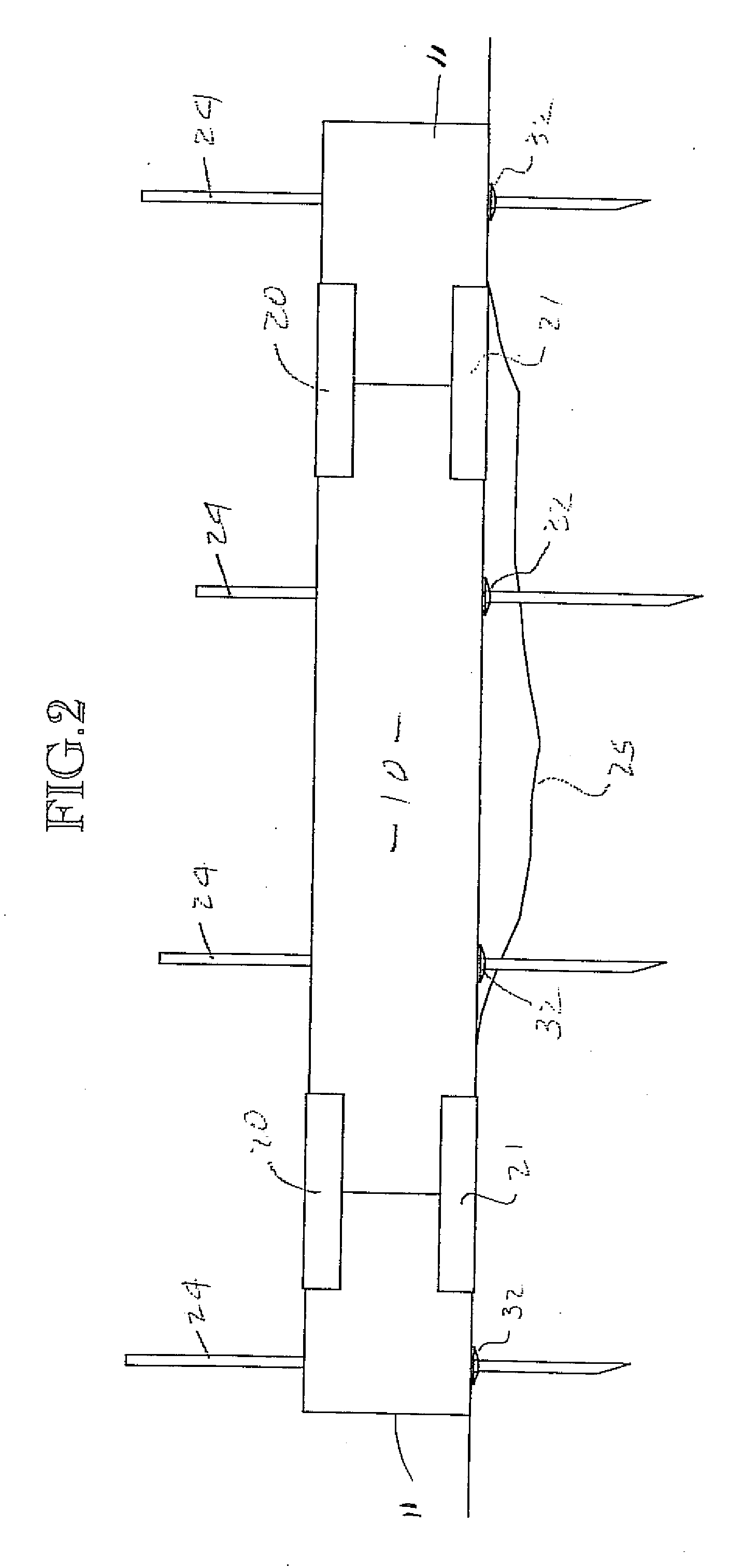

[0031]FIG. 1 shows a form section of the type that is disclosed herein. As seen in FIG. 1, the side walls 10 and 11 of the form section of the embodiment depicted in the figure, are composed out of a have a pair of opposed corrugated plastic sheets 2 and 4 with spaced, integral interconnecting ribs in between corrugated plastic sheets 2 and 4. The channels or spaces between the interconnecting ribs are oriented at a right angle to the long axis of the side walls such that the resulting channels are vertical when the side wall is placed on the substrate at a job site. FIG. 3 shows a form section composed of two side walls of the type that is disclosed herein.

[0032]In one preferred embodiment, the side walls of the form section are ten feet in length, and the stakes 24 are placed abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com