Heat exchanger

a heat exchanger and heat exchanger technology, applied in the field of heat exchangers, can solve the problems of increasing manufacturing costs, and achieve the effect of reducing the steps of manufacturing the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

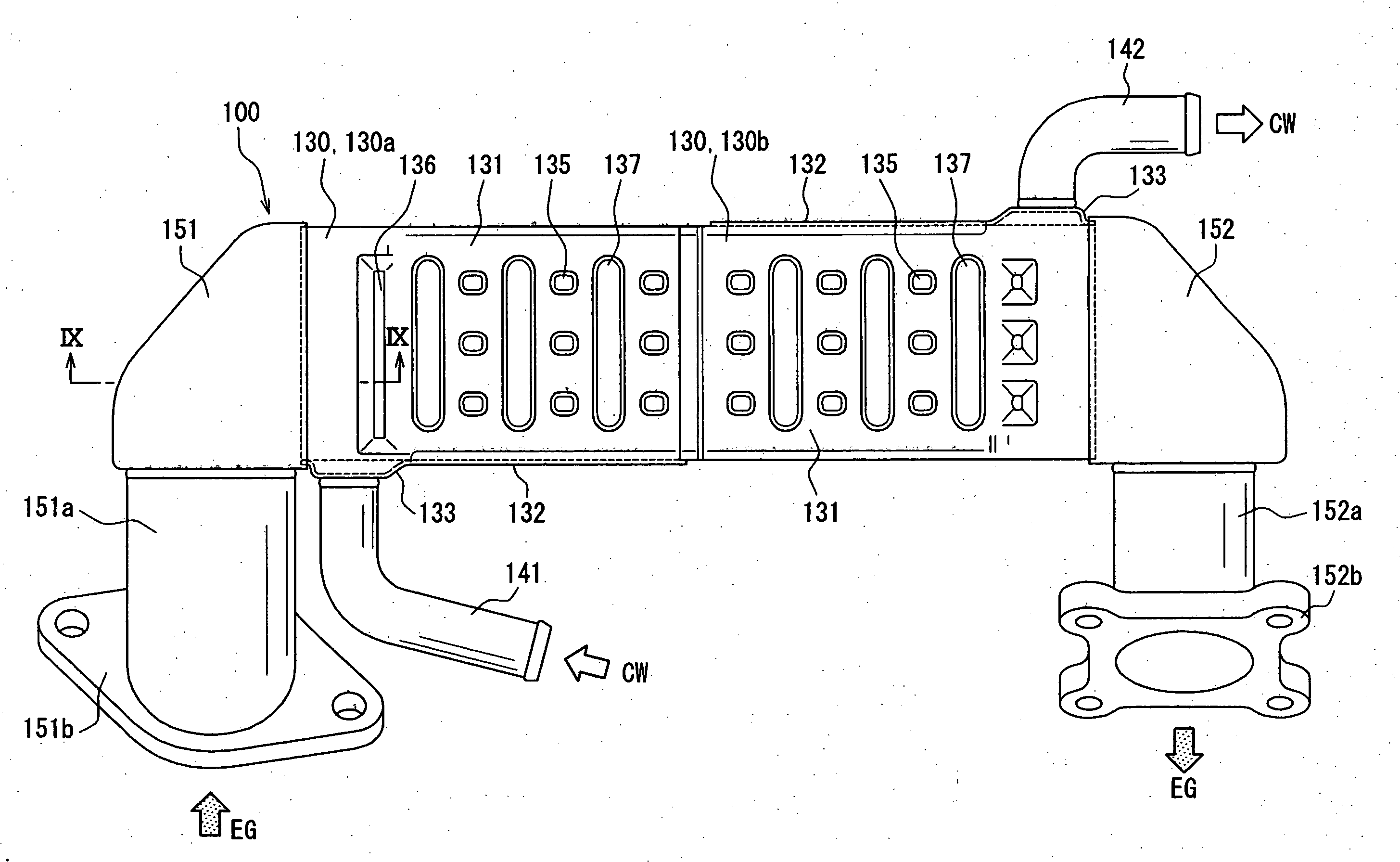

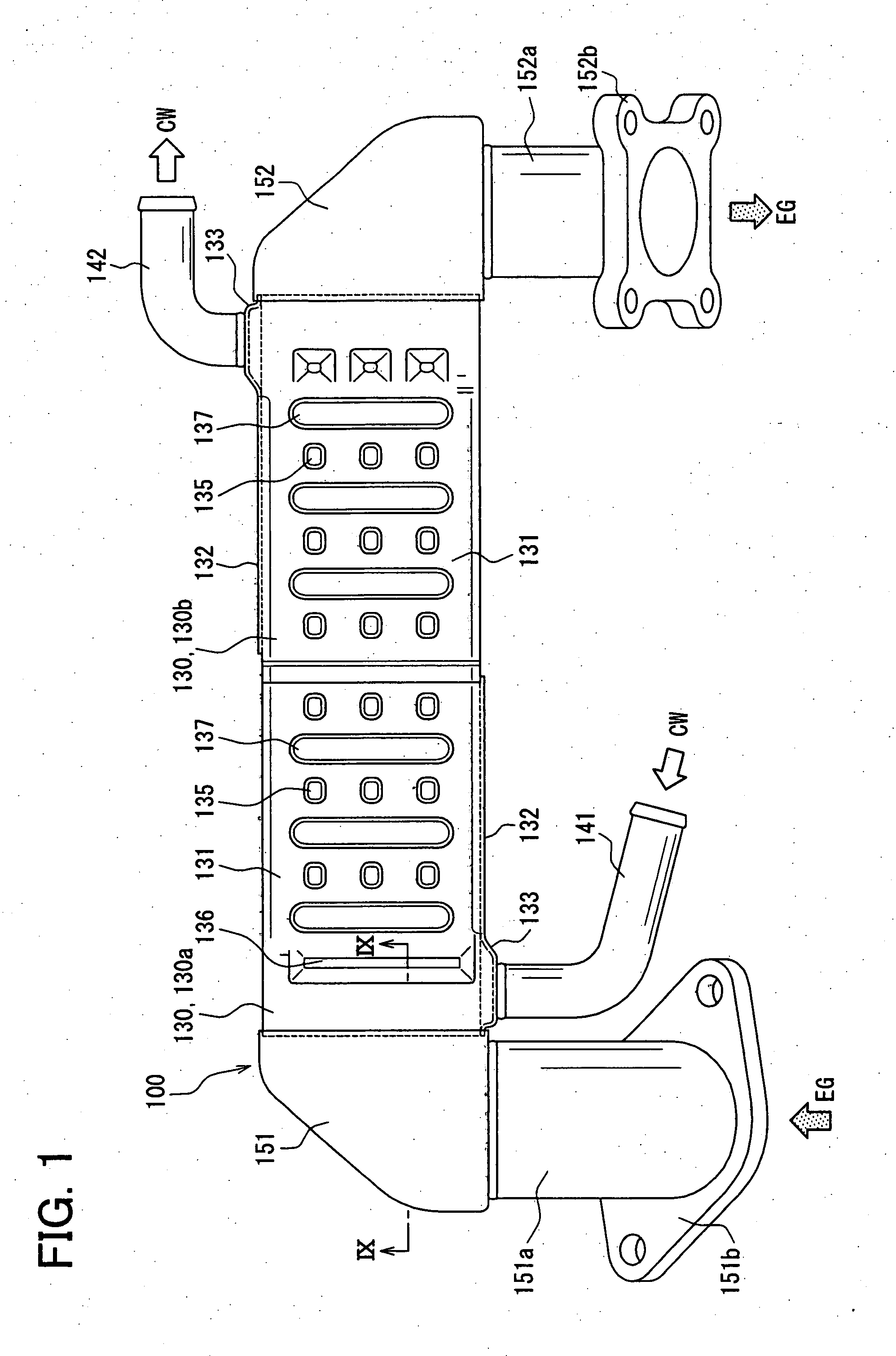

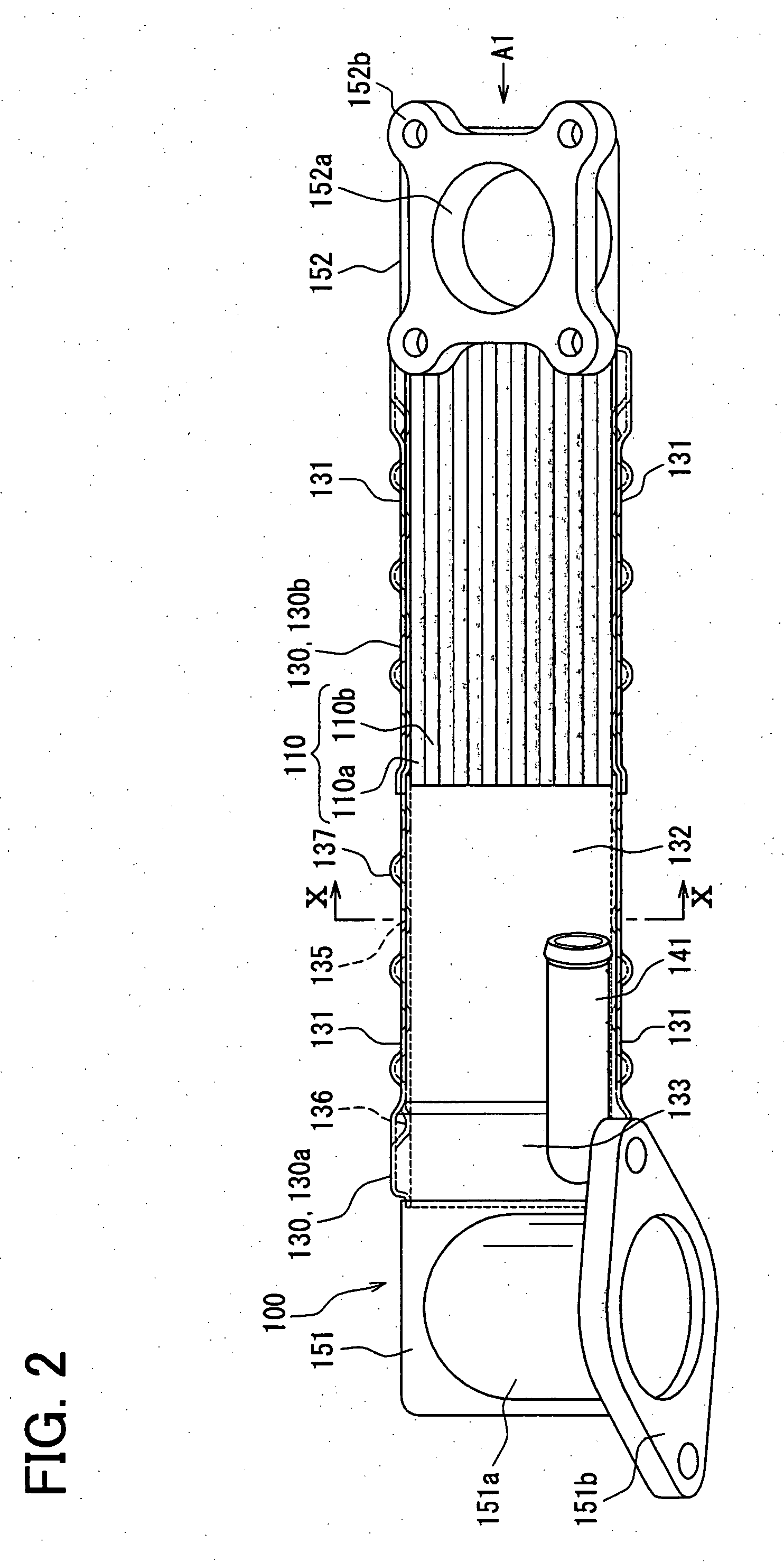

[0081]A second embodiment will be described with reference to FIG. 13. In the second embodiment, a EGR gas cooler 100A has bypass tubes 110A and a partition wall 160 in addition to the structure of the EGR gas cooler 100 of the first embodiment. In FIG. 13, the water inlet part is exemplary shown because a water inlet part and a water outlet part have the similar structure.

[0082]The bypass tubes 110A are stacked on one side (lower side in FIG. 13) of the stack of the tubes 110. The bypass tubes 110A define the gas passages 114 through which the exhaust gas flows, similar to the tubes 110. The partition wall 160 is interposed between the tube 110 and the bypass tube 110A. The partition wall 160 is for example made of stainless and has a rectangular shape. The stack of the tubes 110, partition wall 160 and bypass tubes 110A is disposed in the water tank 130.

[0083]Similar to the first embodiment, the water tank 130 includes the first tank member 130a and the second tank member 130b. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com