Angular position and velocity estimation for synchronous machines based on extended rotor flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

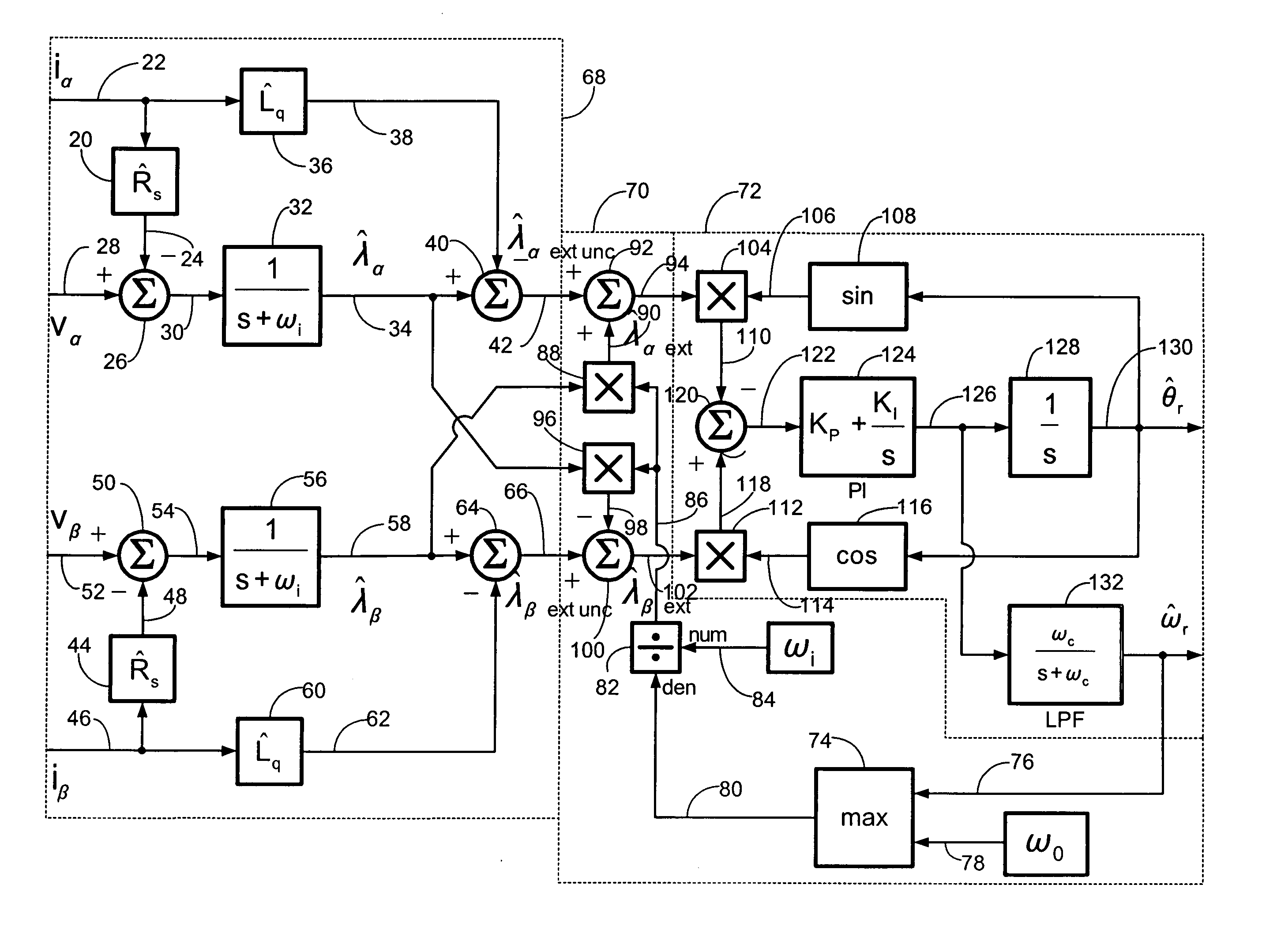

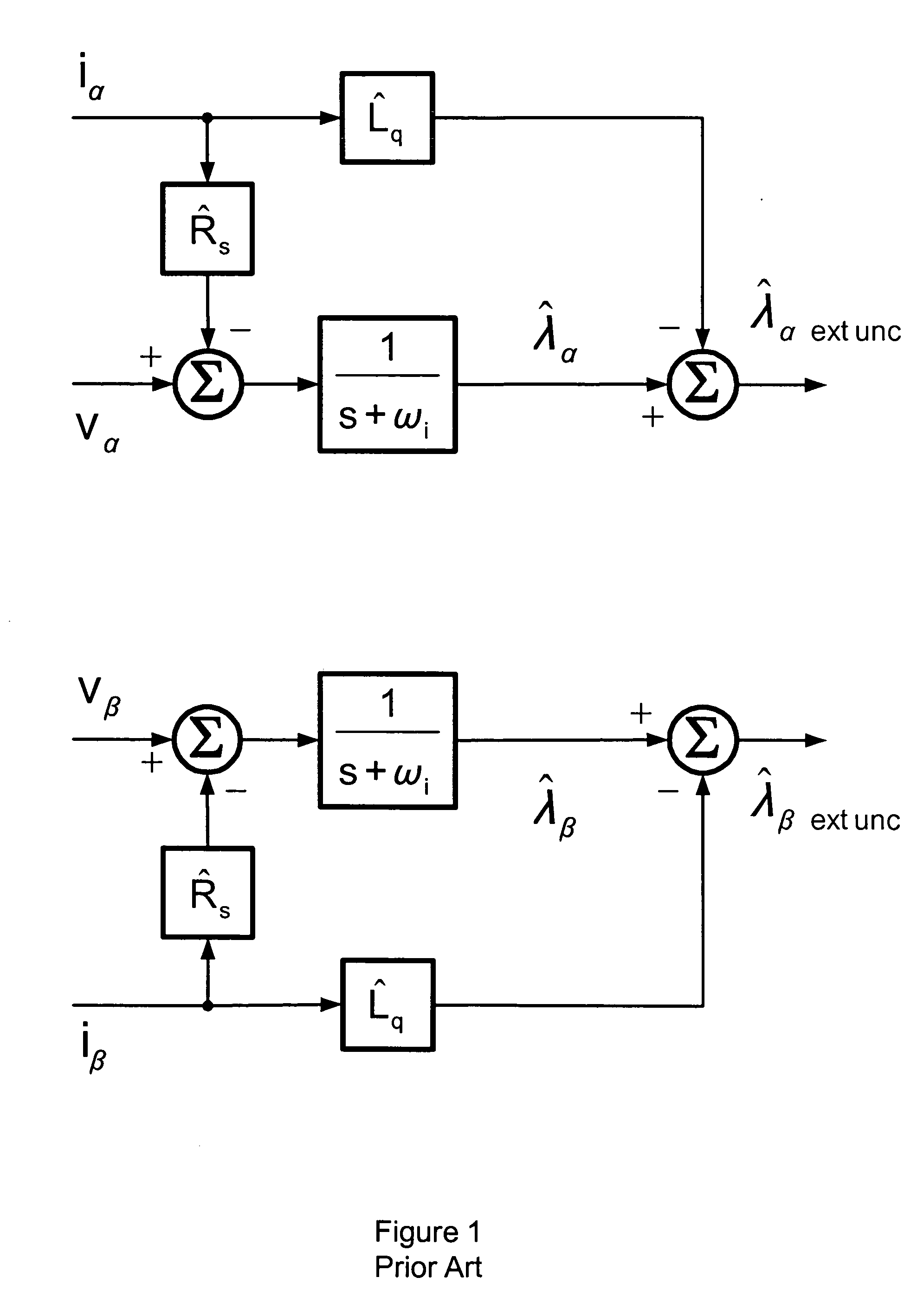

[0012] For Extended Flux Sensorless (EFS) control of a synchronous dynamoelectric machine, the following differential equations estimate the stator flux linkages in the α-β two-axis stationary reference frame using a lag approximation to a pure integrator: ⅆλ^αⅆt=vα-R^s×iα-ωefs×λ^α(1)ⅆλ^βⅆt=vβ-R^s×iβ-ωefs×λ^β(2)

where, [0013]λα−α-axis stator flux estimate: V-sec [0014]λβ=β-axis stator flux estimate; V-sec [0015] vα=α-axis stator potential; V [0016] vβ=β-axis stator potential; V [0017] iα=α-axis stator current; A [0018] iβ=β-axis stator current; A [0019] {circumflex over (R)}s=estimated stator resistance; Ohm [0020]ωi=lag function corner frequency; sec−1

[0021] For alternating current (AC) steady state analysis, the transformation of these differential equations into Laplace transform notation is: λ^α=vα-R^s×iαs+ωi(3)λ^β=vβ-R^s×iβs+ωi(4)

where [0022] s=Laplace operator; sec−1

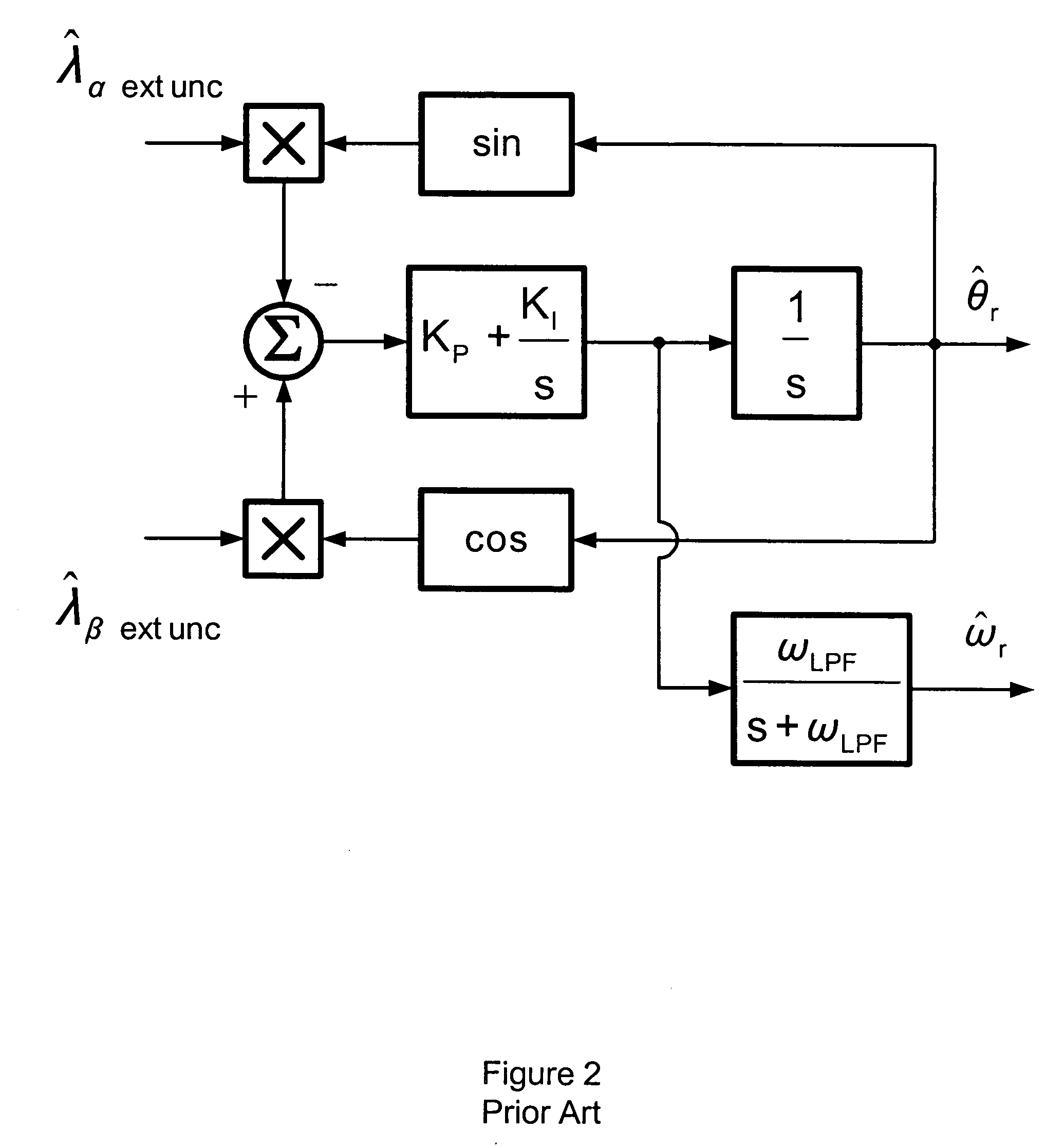

[0023] The magnitudes of these two stator flux linkage estimates at an estimated electrical frequency Of {c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com