Device for supporting, aligning, and cooling a solar panel

a solar panel and device technology, applied in the direction of solar heat collector mounting/support, solar heat collector safety, light and heating apparatus, etc., can solve the problems of photovoltaic cells diminishing in output and degrading under high temperatures, and achieves a greater sweep, preventing desiccation, and reducing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

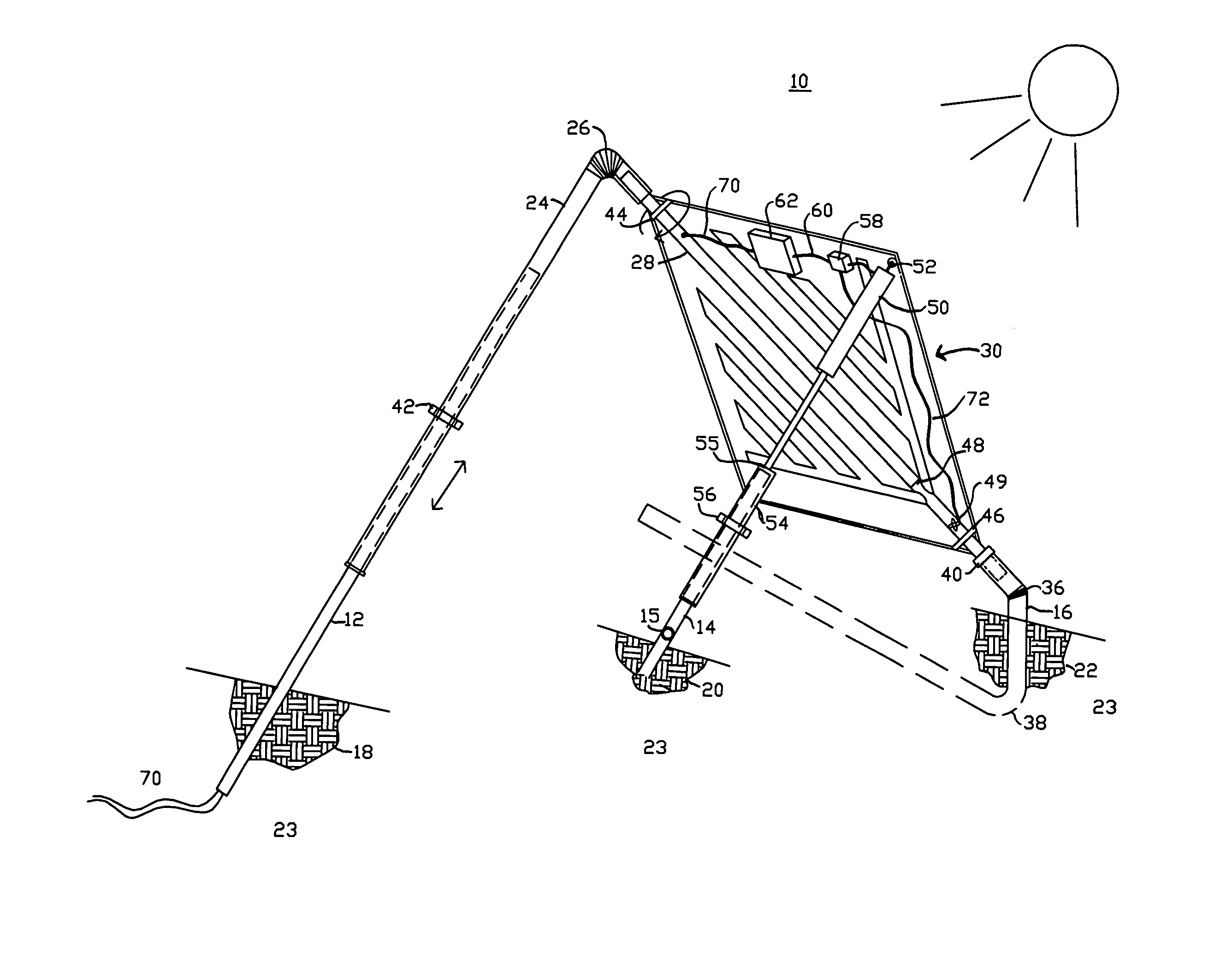

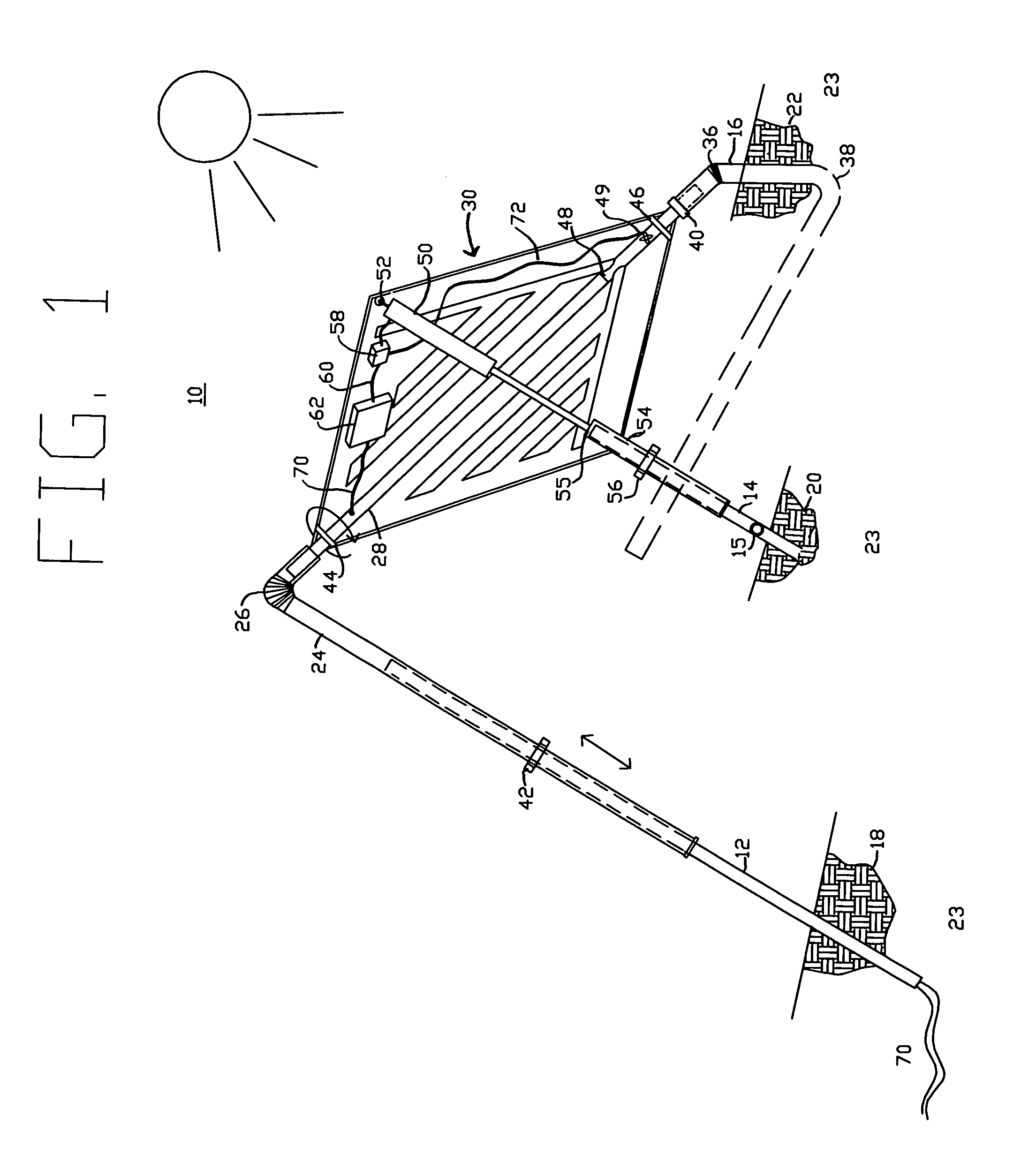

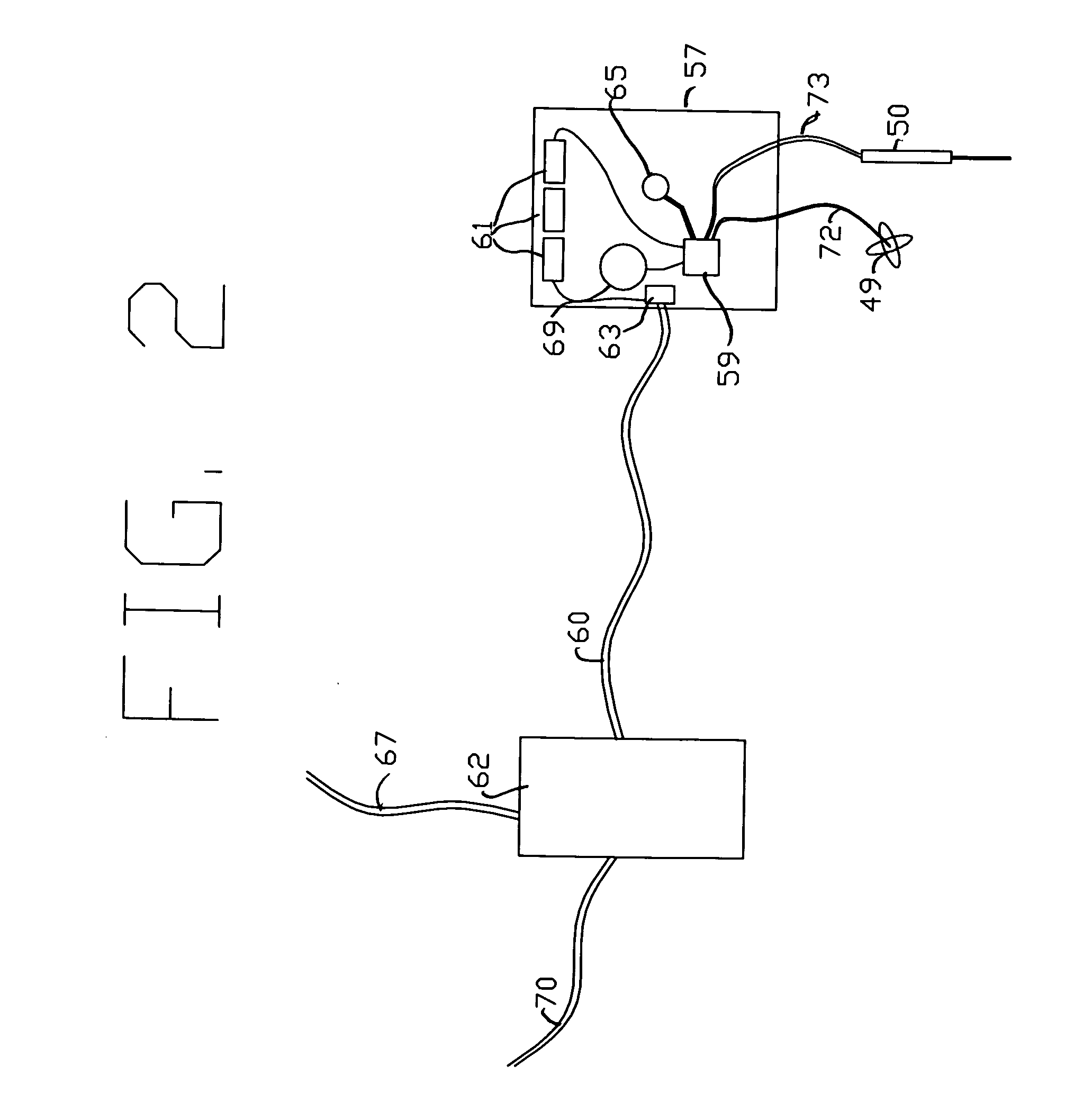

[0013] A solar panel support 10 shows embodiments as depicted in FIG. 1. Support members include pipes 12, 14, 16 anchored into concrete footings 18, 20, 22. Concrete footings 18, 20, 22 provide support to download dead and live loads and uplift forces transmitted by pipes 12, 14, 16. Pipe 12 and 16 extend through the concrete 18 and 22, respectively. Pipes 12, 14, 16 are rigidly constrained within concrete 18, 20, 22. Concrete 18, 20, 22 are contained by earth 23. Pipe 12 and Pipe 16 are arranged generally on a polar axis, Pipe 12 being closer to the pole. Pipe 14 includes a pivot linkage 15 providing a range of motion over a cone of approximately 30 degrees along the axis. An extension cover pipe 24 contains a flexible segment 26 and is sized for containment of attachment member 28. Attachment member 28 is generally a hollow pipe, however other shapes are embodied. Pipe 16 contains a flexible segment 36 as shown. Pipe 16 passes through concrete footing 22 and is attached to a buri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com