Poly (diol co-citrate) hydroxyapatite composite for tissue engineering and orthopaedic fixation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Biodegradable Elastomeric Polymers

[0068] The compositions of the invention are based on biodegradable elastomeric polymers of poly(diol) citrate molecules. Such molecules typically comprising a polyester network of citric acid copolymerized with a linear aliphatic di-OH monomer in which the number of carbon atoms ranges from 2 to 20. Polymer synthesis conditions for the preparation of these molecules vary from mild conditions, even at low temperature (less than 100° C.) and no vacuum, to tough conditions (high temperature and high vacuum) according the requirements for the materials properties. By changing the synthesis conditions (including, but not limited to, post-polymerization temperature, time, vacuum, the initial monomer molar ratio, and the di-OH monomer chain length) the mechanical properties of the polymer can be modulated over a wide range. This series of polymers exhibit a soft, tough, biodegradable, hydrophilic properties and excellent biocompatibility in vitro.

[0069]...

example 2

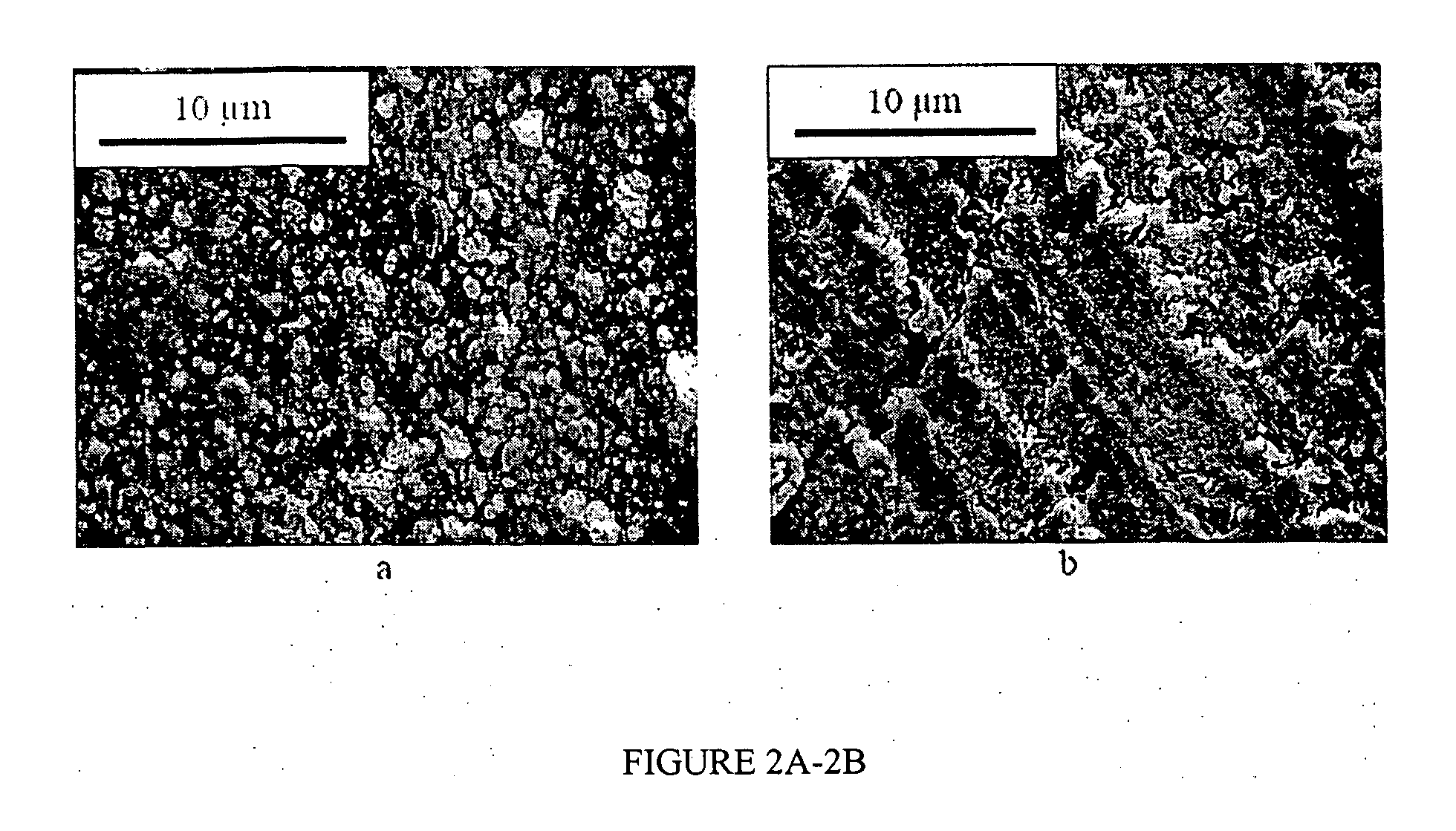

Materials and Methods used in Preparing and Characterizing Biodegradable Elastomeric Composites made from POC and Bioceramics

[0083] Example 1 describes the production of PDC as well as a number of other poly(diol)citrate polymers. In the present Example, there are provided teachings of how to further strengthen and stiffen is the poly(diol)citrate polymers by incorporating ceramics into the elastomeric polymer matrix.

[0084] Materials and Methods

[0085] Materials: Hydroxyapatite [Mw: 502.32, Assay>90 (as Ca3 (PO4)2), 0.5%>75 um, 1.4% between 45-75 um, 98.1%<45 um] was purchased from Fluka (St. Louis, Mo., USA). 1,8-octanediol (98%) and citric acid (99.5%) were purchased from Sigma-Aldrich (St. Louis, Mo., USA). These materials were used as received. PTFE tubes were purchased from McMaster-CARR, Chicago, USA.

[0086] Sample preparation: POC pre-polymer was synthesized according to published methods [1,5]. Briefly, 0.05 mol of 1,8-octandiol and 0.05 mol of citric acid were added to a ...

example 3

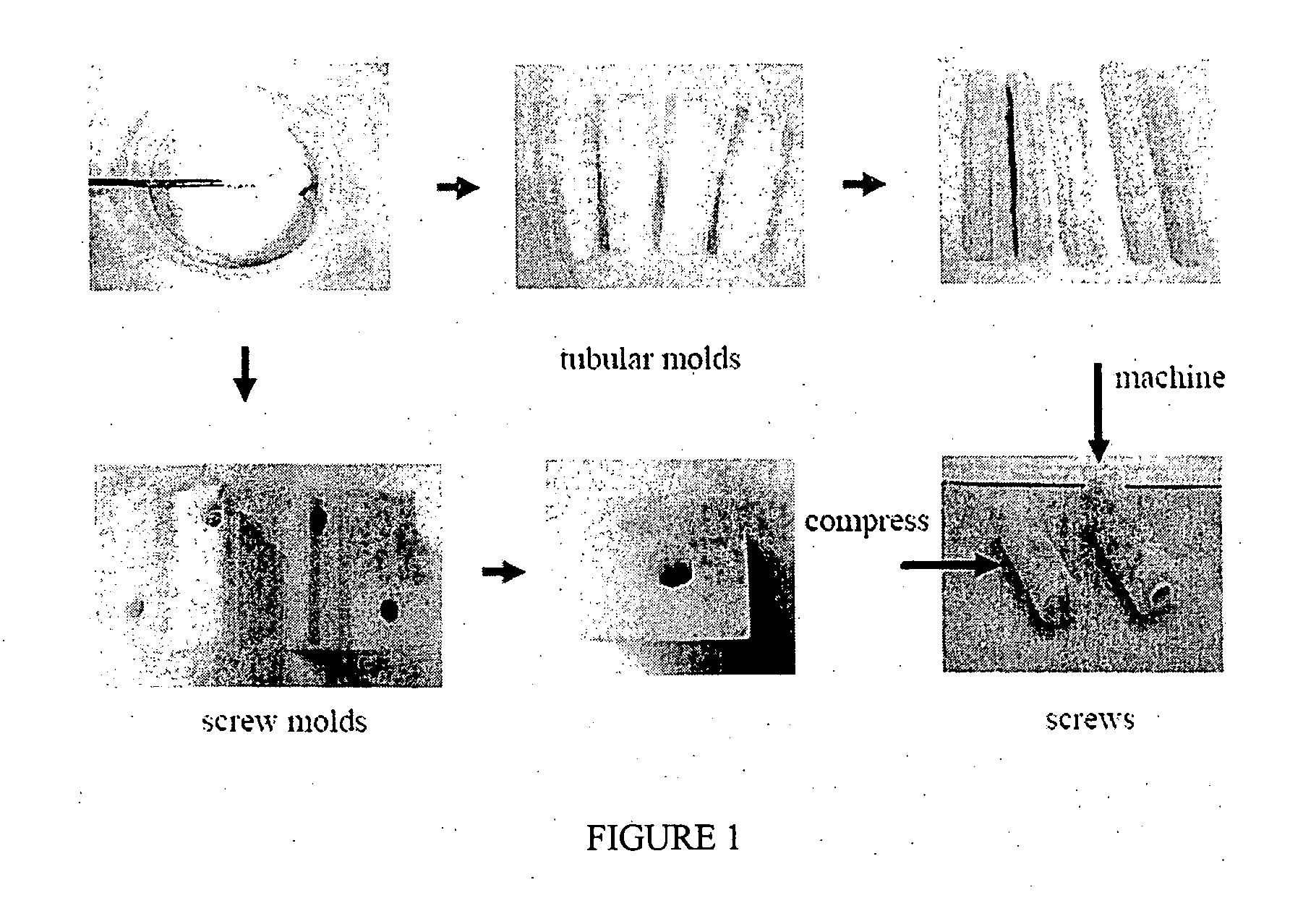

Preparation and Analysis of Bone Screws made from Composites of POC and Bioceramics

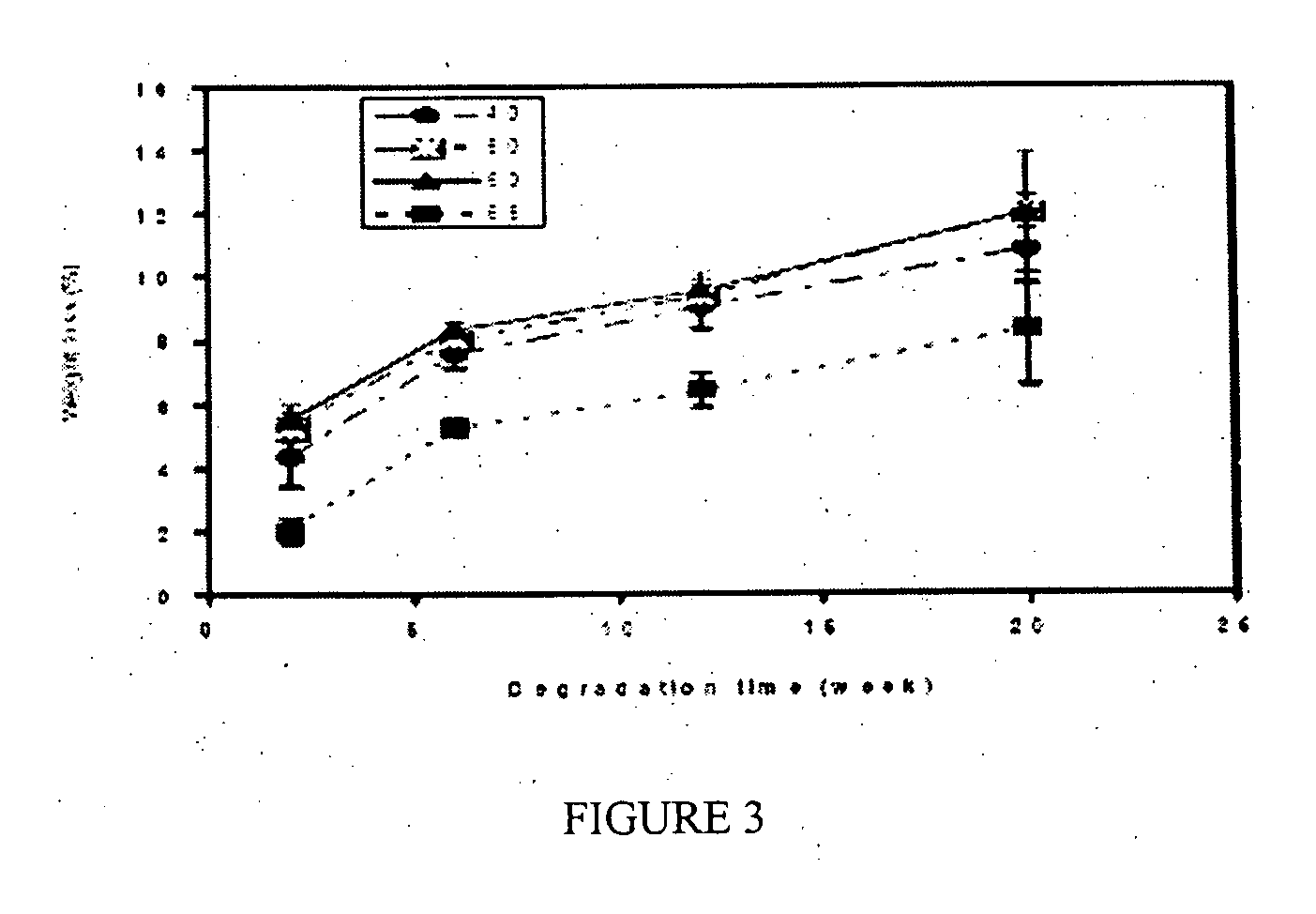

[0094] POC-HA composites having HA fraction of 40 wt. %, 50 wt. %, 60 wt. %, 65 wt. % HA were investigated for bone screws. Using compression molding method, POC-HA composites with HA from 40-65 wt. % were compressed into molds of rods and screws. The POC-HA rods obtained were strong enough to be further machined into screws. The POC-HA screws from compression molding and machining methods were shown in FIG. 1.

[0095] Characterization of the mechanical properties of composites. The mechanical property measurements (bending, compression, shear, tension and torsion) are summarized in Table 1.

TABLE 1Effect of HA fraction on mechanical properties of POC-HA compositesPOC-HAρSbEbScEcStEtSsTsComposite(Wt %)(g / cm3)(MPa)(MPa)(MPa)(MPa)(MPa)(MPa)(MPa)(N · m)HA 4040 / 601.60933.927532.01897.821.423.322.9(±0.016)(±5.7)(±80)(±13.0)(±21)(±0.5)(±1.8)(±1.6)(±1.6)HA 5050 / 501.65337.732364.02647.130.225.124.2(±0.014)(±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com