Displacement type compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

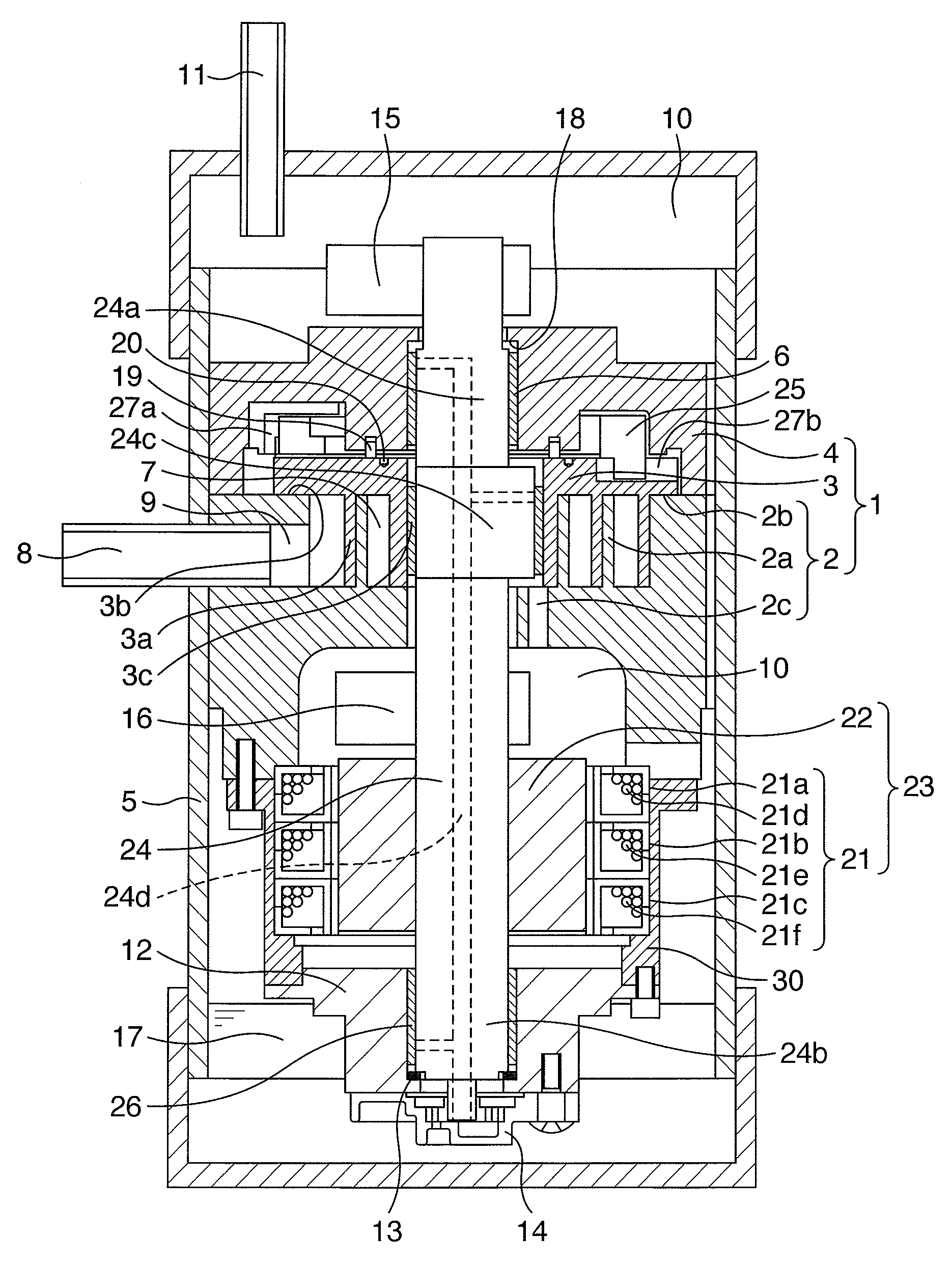

[0050]A displacement type compressor according to the present invention will now be described with reference to FIG. 7. FIG. 7 shows the entire structure of a rotary compressor.

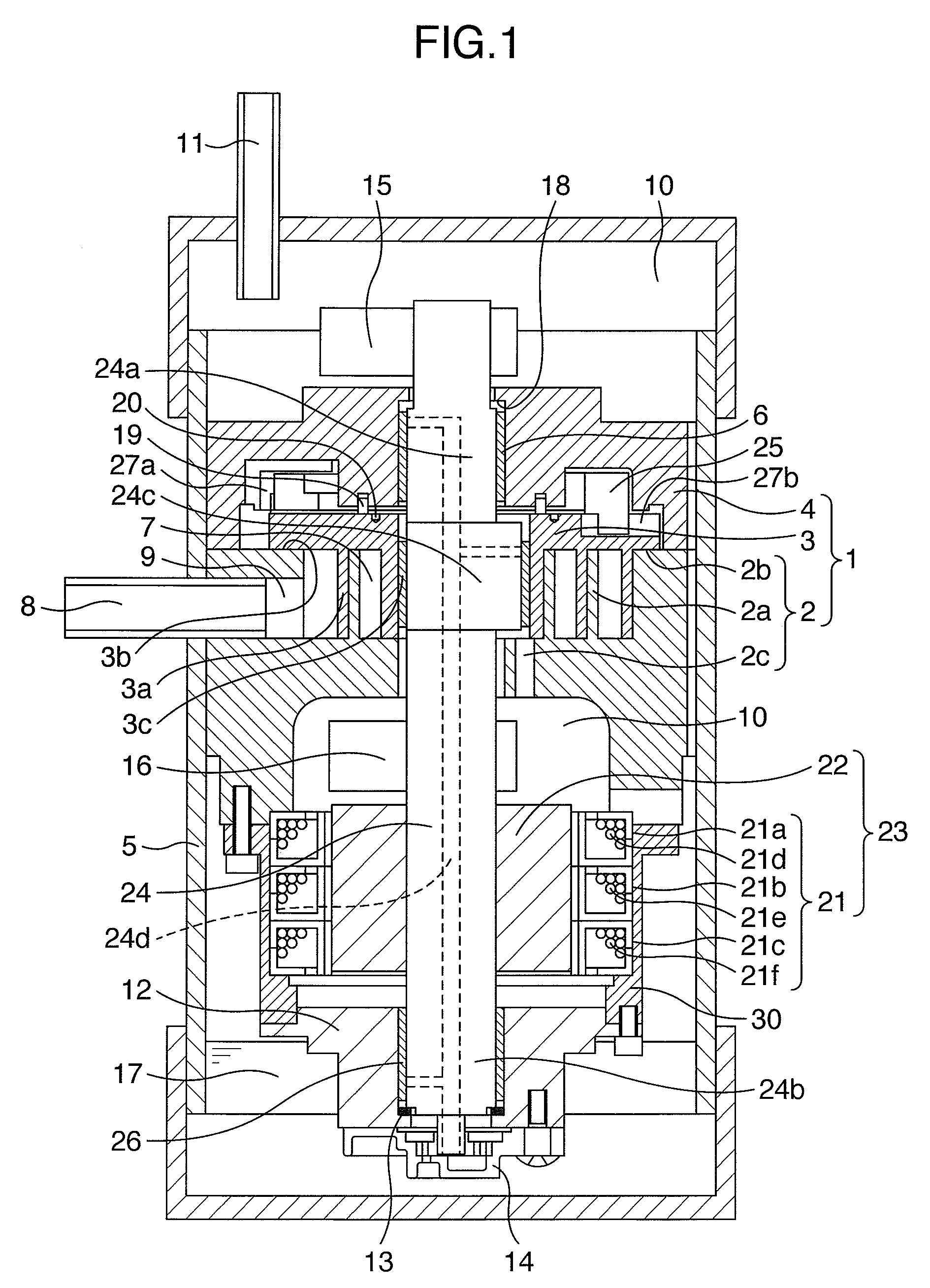

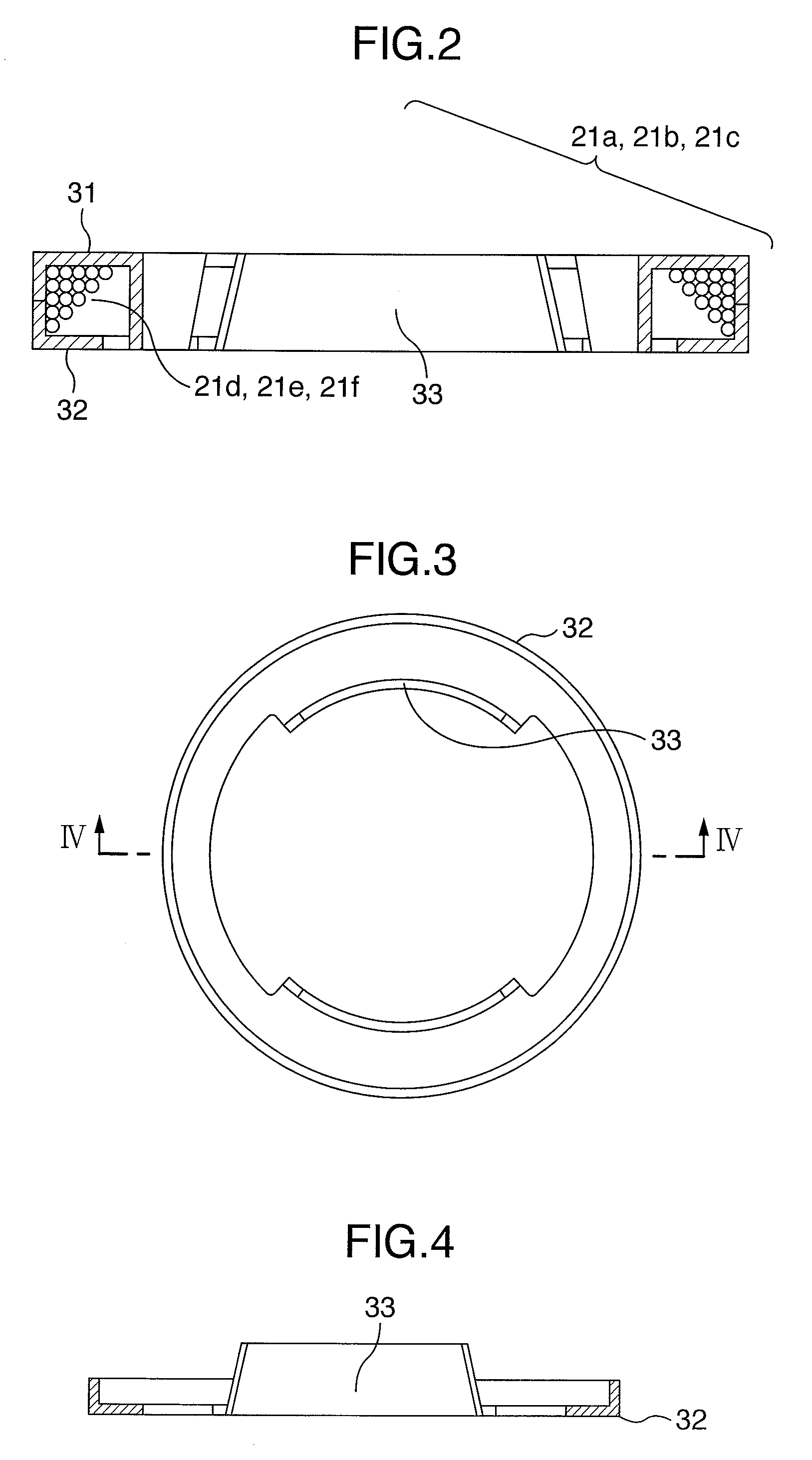

[0051]A drive source is a motor 23 which is comprised of a stator 21 comprising stator cores 21am 21b and 21c each constituted of claw-type core portions formed of a magnetic powder and meshed with each other and annular coils 21d, 21e and 21f, and a rotor 22. The stator cores 21a 21b and 21c are contained in a core frame 30.

[0052]A compressing mechanism section 101 of the rotary compressor is comprised of a cylinder 102, a first end plate 103 and a second end plate 104 for closing opposite ends of the cylinder 102, a roller 105 disposed in a space surrounded by the cylinder 102, the first end plate 103 and the second end plate 104, and a vane (not shown) having a function of changing the volume of a space defined by the cylinder 102, the first end plate 103, the second end plate 104 and the roller 105 in acc...

fourth embodiment

[0059]A displacement type compressor according to the present invention will now be described in detail with reference to FIG. 8. FIG. 8 shows the entire structure of a rotary compressor.

[0060]For a shaft support portion for a crankshaft 120, a shaft support portion 140 is provided on a second end plate 104. A thrust bearing 141 and a thrust bearing 131 for supporting an axial force of the crankshaft 120 are formed on the side of the eccentric pin portion 120c of the crankshaft 120 closer to the motor and at the first end plate 103, respectively, but both of the thrust bearings may be formed at opposite ends of the eccentric pin portion 120c of the crankshaft, and in the latter case, it is possible to provide a further simplification.

fifth embodiment

[0061]A displacement type compressor according to the present invention will now be described in detail with reference to FIG. 9. FIG. 9 shows the entire structure of a rotary compressor.

[0062]This displacement type compressor has a feature in that a compressing mechanism section 154 is disposed in a lower portion of a closed container 112 and balance weights 150 and 151 are disposed at opposite ends of a rotor 22. The balance weights 150 and 151 need not be engaged directly with the rotor 22, and may be disposed on a crankshaft. A thrust bearing 153 and a thrust bearing 152 for supporting an axial force of the crankshaft 120 are formed at opposite ends of an eccentric pin portion 120c of the crankshaft 120 for the purpose of the simplification. In place of the provision of the thrust bearing 153, a thrust load can be received on a first end plate itself, and in this case, it is possible to provide a further simplified structure.

[0063]As described above, a resinous film can be appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com