Support structure for a planar cooling device

a support structure and cooling device technology, applied in indirect heat exchangers, lighting and heating apparatus, instruments, etc., can solve the problems of increasing the difficulty of keeping various electronic devices cool enough for optimal performance, reducing the overall thickness of the device, and not providing an adequate solution to heat generation in these devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0033]FIG. 3 is an exploded perspective view of the cooling device in accordance with the invention, FIG. 4 is a cross-sectional view of the cooling device of FIG. 3, and FIG. 5 is a close-up view of a portion of the support structure in the cooling device of FIG. 3.

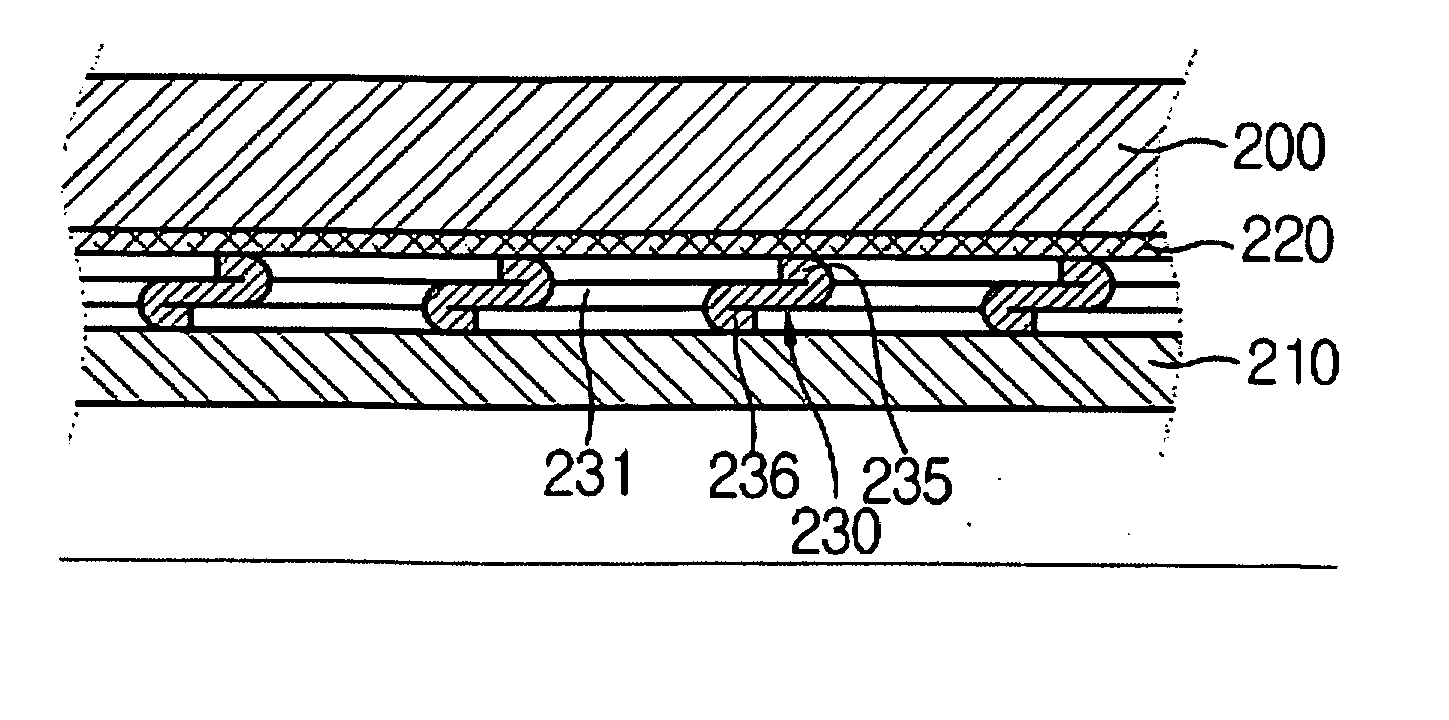

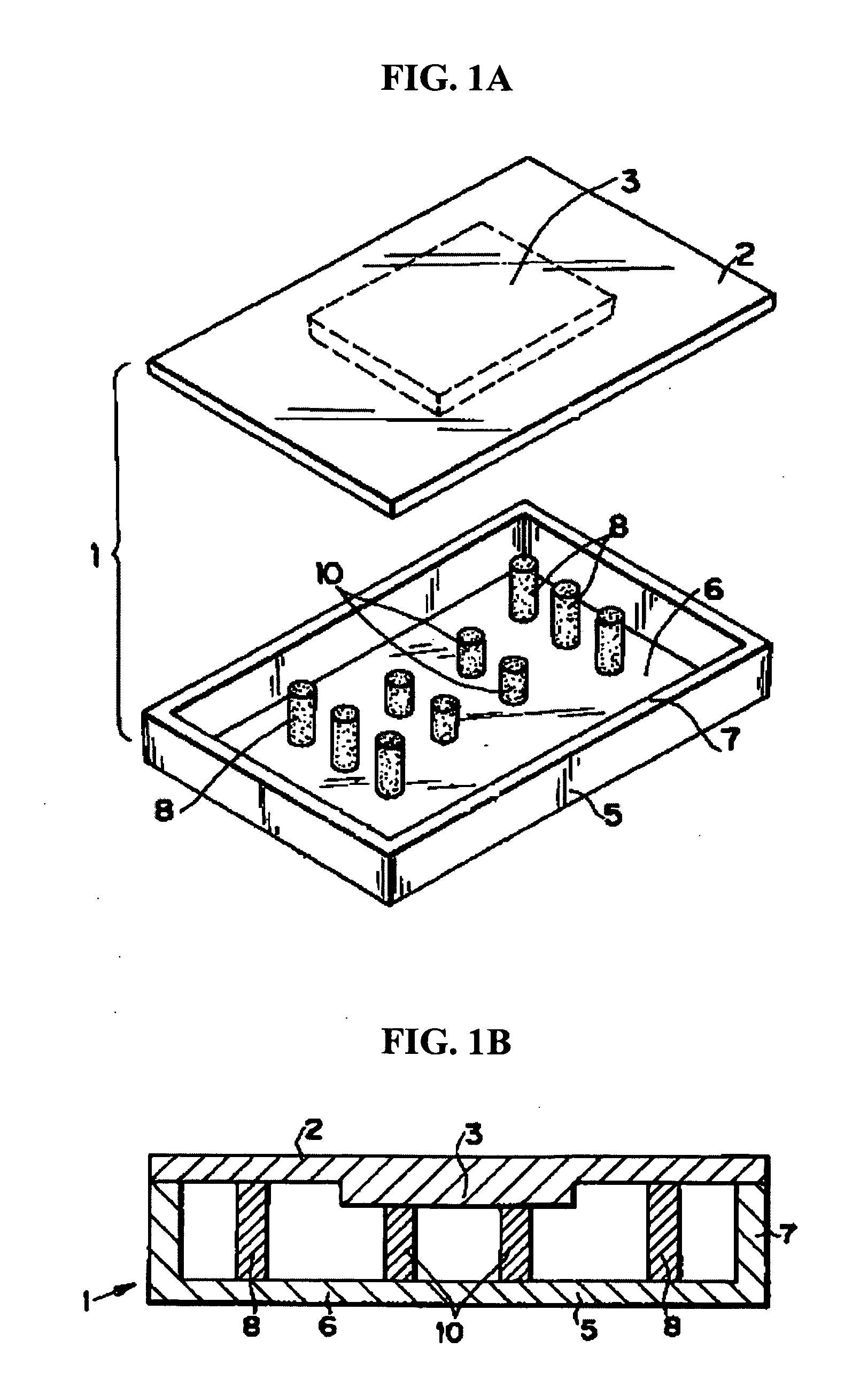

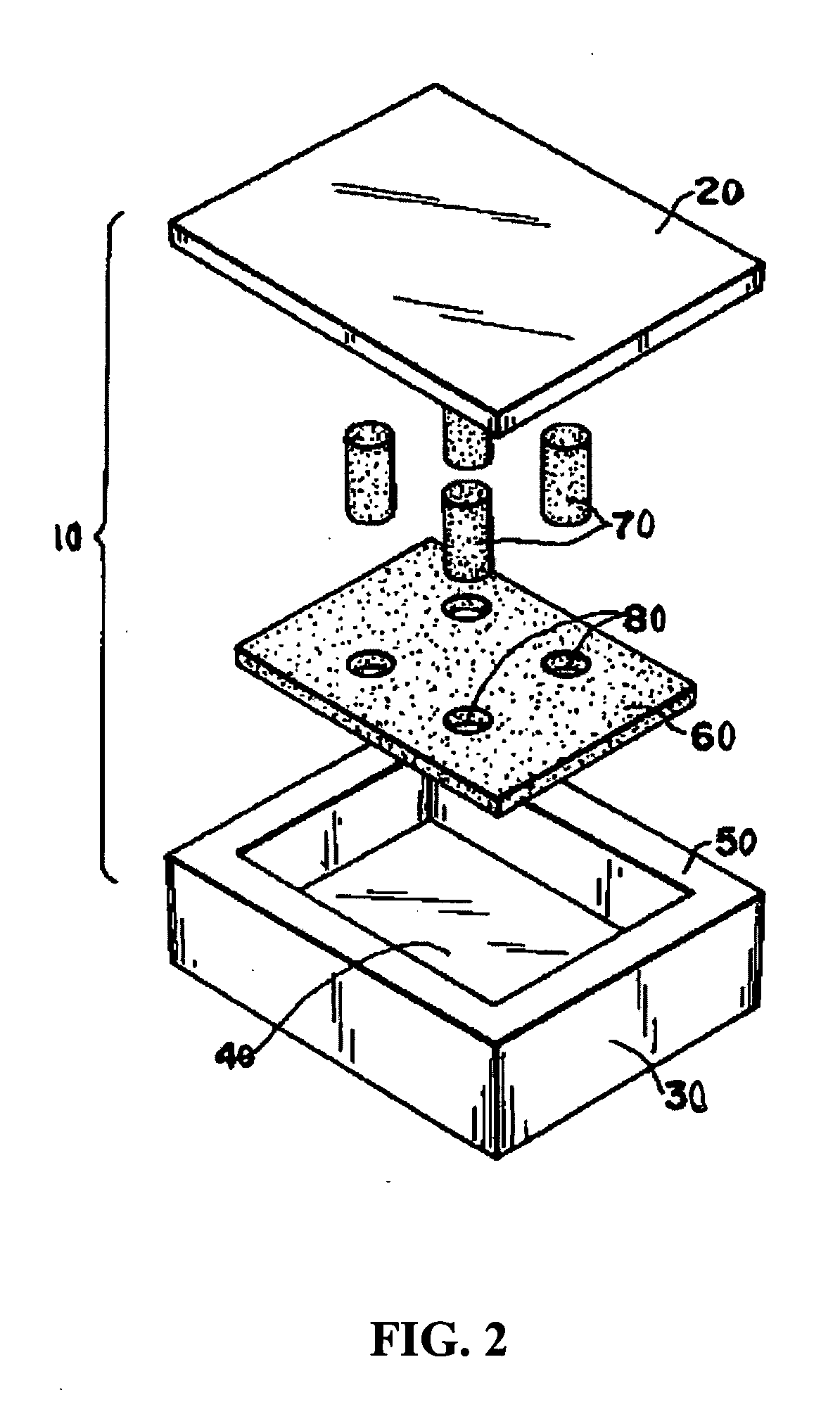

[0034] As shown in FIG. 3, the cooling device of the invention includes a casing made of a first plate 200 and a second plate 210. The first plate 200 and the second plate 210 may be combined to form an enclosed space between the two plates 200, 210. The two plates 200, 210 may be sealed together to form the enclosed space so that a coolant fluid (e.g., water, methanol, ethanol) is contained in the enclosed space. The seal may be formed around the edges so as to not intrude upon the enclosed space. Either or both of the first and second plates 200, 210 is designed so that it can be attached to a printed circuit board (PCB) or a chip. For example, the first plate 200 may have a flat surface that can easily be attached to ...

second embodiment

[0047]FIG. 8 is an exploded perspective view of the cooling device in accordance with the invention. As shown, the cooling device of the multi-wick embodiment includes the first plate 200, the second plate 210, and the support structure 330. In addition, the cooling device includes a first wick layer 220a and a second wick layer 220b positioned between the support structure 330 and one of the plates 200, 210, respectively. The support structure 330 is, therefore, located between the two wick layers 220a, 220b. Details of the support structure 330 were provided above in reference to FIG. 6. The cooling device of FIG. 8 may be made with the support structure 230 or 430 as well. The multi-wick embodiment of the cooling device works particularly well when there are two heat sources, one near each of the two plates 200, 210. In the case where there are two heat sources, the parts of the cooling device that are closest to the two heat sources act as evaporation areas, and condensation occ...

third embodiment

[0048]FIG. 9 is the cooling device in accordance with the invention. The finned-embodiment that is shown is substantially similar to the embodiment of FIG. 3 except that it has fins 213 on the lower plate 211 to increase the heat exchange surface. In this embodiment, the first plate 210 is designed so it can be positioned adjacent to a heat source. The coolant fluid evaporates on the side of the support structure 230 that is closer to the first plate 200, then expands into the side that is closer to the second plate 210 through the openings 231. Optionally, each of the fins 213 is designed with a hollow space 215 so that the coolant fluid can travel inside the fins 213 for a more effective heat dissipation. However, the fins 213 being designed to hold coolant fluid is not a requirement of the invention. The presence of the fins 213, even without the hollow spaces 215, aids heat dissipation by increasing the heat exchange surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com