Sewing Machine

a sewing machine and needle technology, applied in the field of sewing machines, can solve the problems of inability to increase the cost of the machine, and inability to control the illuminating device, so as to reduce the manufacturing cost of the illuminating device, reduce the size, and reduce the need for manufacturing cost synergistically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will hereinafter be described with reference to the accompanying drawings.

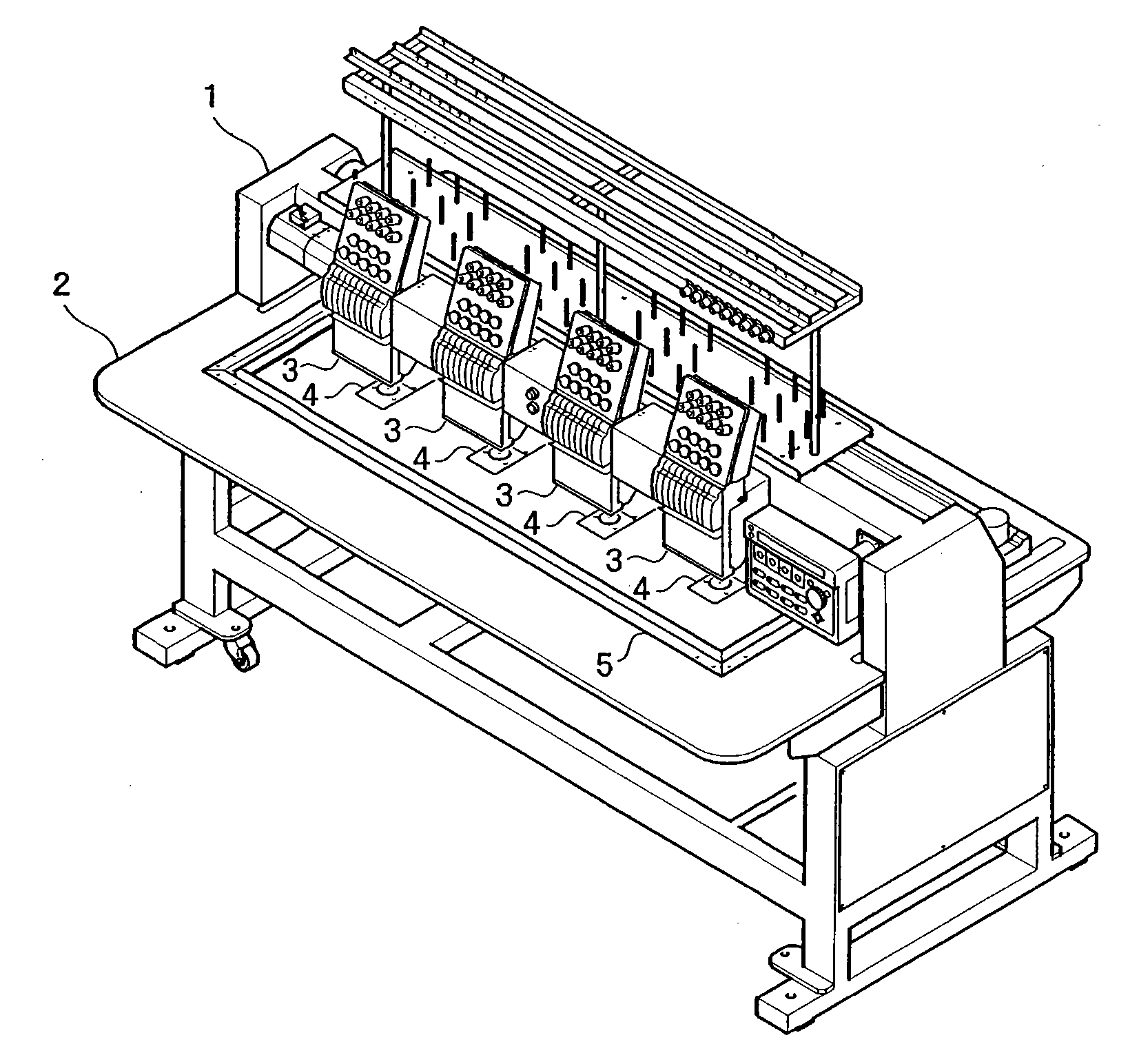

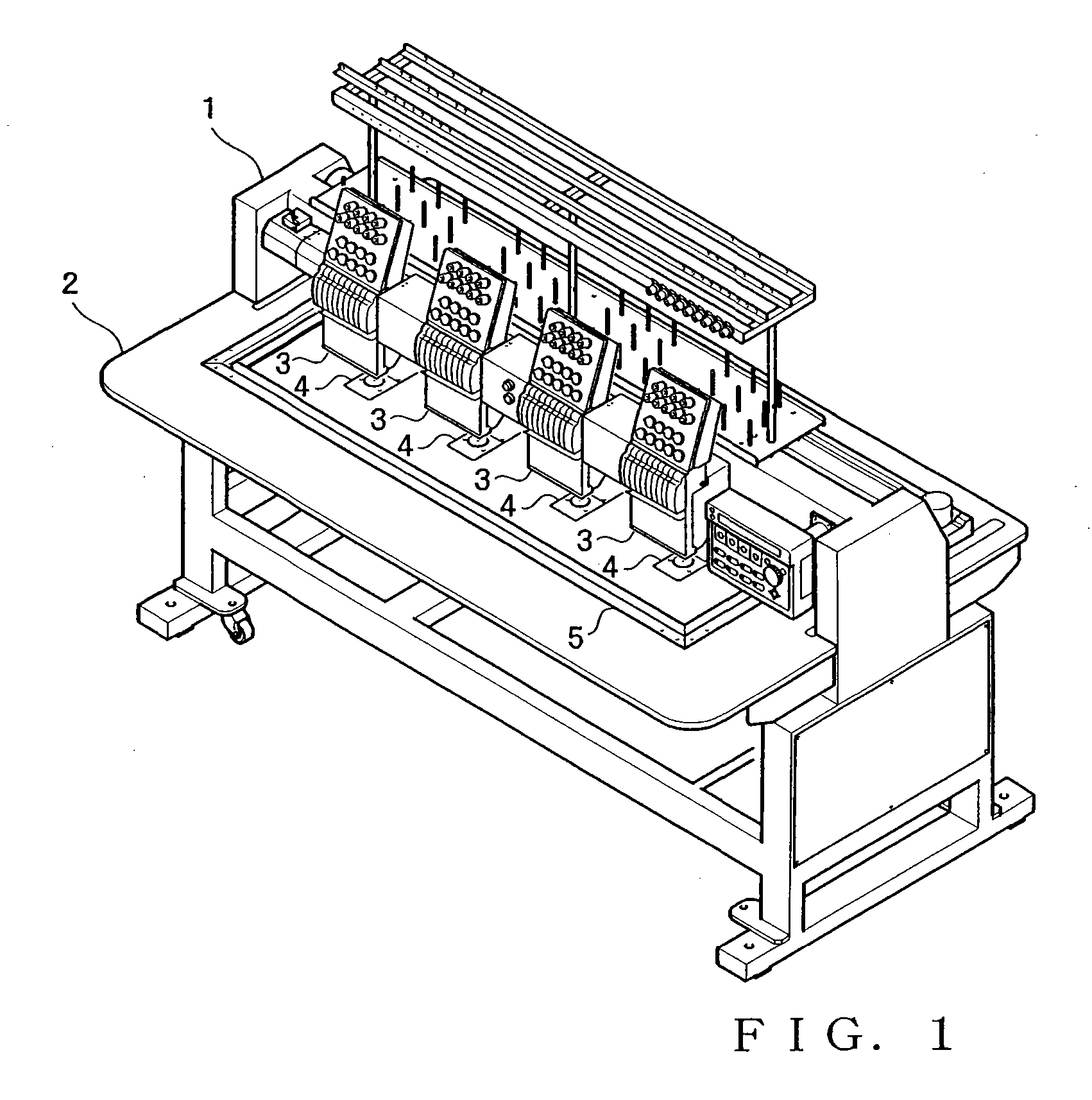

[0018]FIG. 1 is a view showing an outer appearance of a multi-head, multi-needle embroidery sewing machine in accordance with an embodiment of the present invention, where reference numeral 1 indicates a machine frame, and 2 a table. A plurality of (four in the illustrated example) machine heads 3 are disposed at equal intervals along a left-right horizontal direction of the sewing machine, and a needle plate 4 is disposed immediately beneath each of the machine heads 3 and at generally the same height position as the table 2. On the upper surface of the table 2, there is placed an embroidery frame 5 that is driven in front-rear and left-right horizontal directions via an X-axis drive mechanism and Y-axis drive mechanism (not shown).

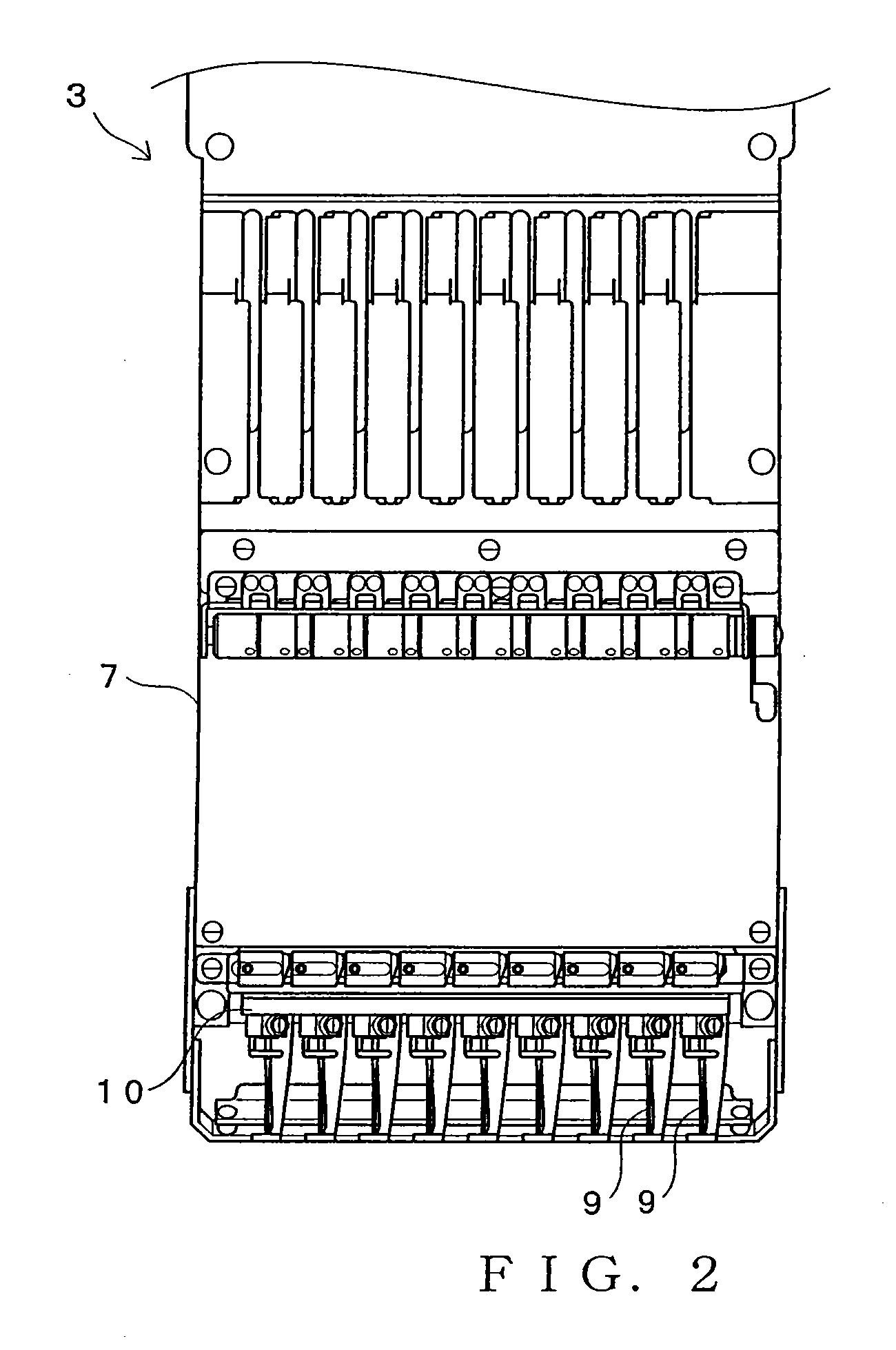

[0019]FIG. 2 is a front view of the machine head 3, and FIG. 3 is a side view (partly in section) of the machine head 3. As clear from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com