Lifting pump for manganese nodules

a lifting pump and manganese nodule technology, applied in the direction of liquid fuel engines, mechanical machines/dredgers, machines/engines, etc., can solve the problems of increasing the cost of mining, reducing the time and cost of mining, and hard and brittle when dried, so as to reduce the cost and time of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Reference will now be made in greater detail to an exemplary embodiment of the invention, an example of which is illustrated in the accompanying drawings. Wherever possible, the same reference numerals will be used throughout the drawings and the description to refer to the same or like parts.

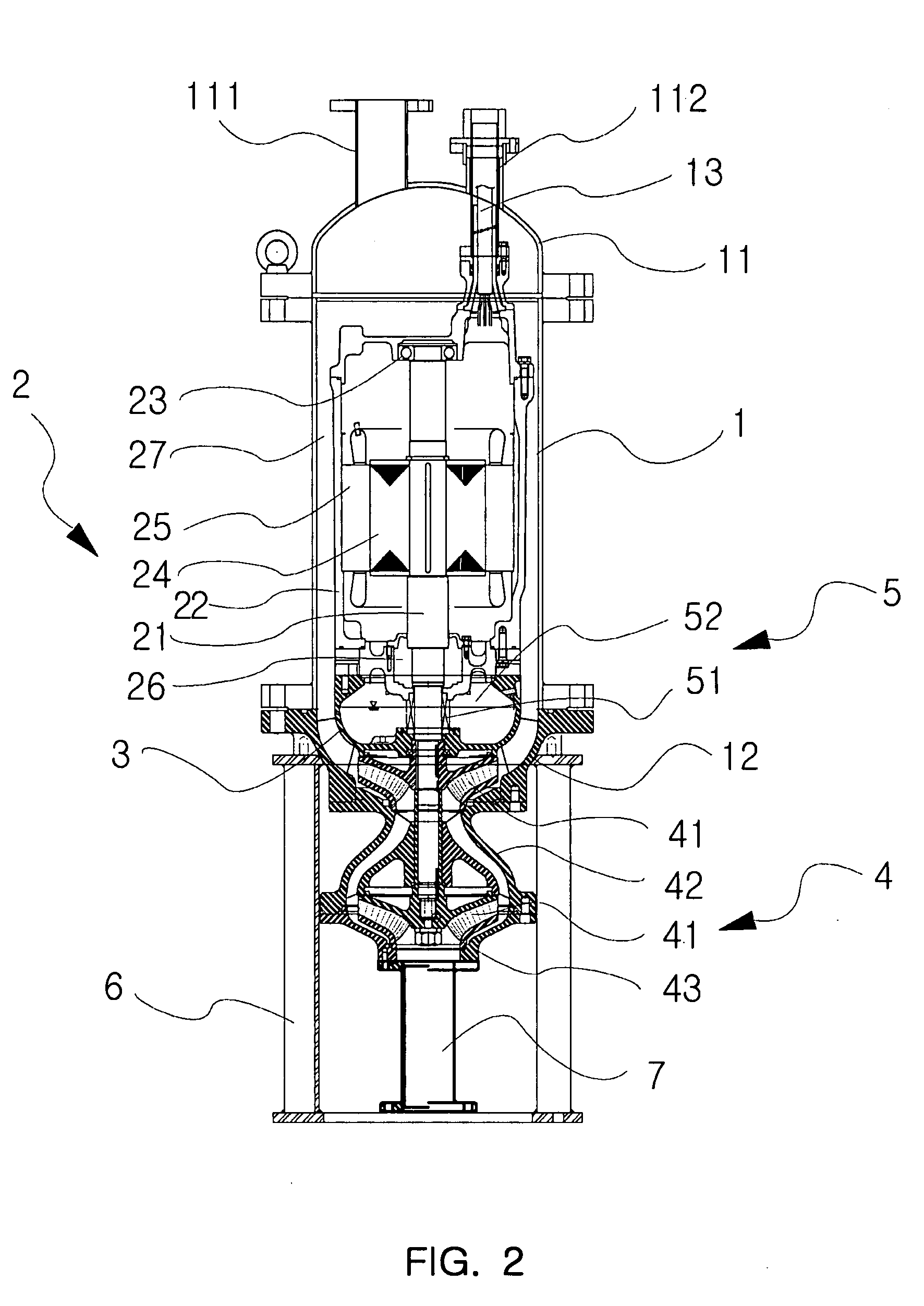

[0037]FIG. 2 is a sectional view illustrating a lifting pump according to an embodiment of the present invention. FIG. 3 is an enlarged sectional view illustrating the important part of a lifting pump according to an embodiment of the present invention. FIG. 4 is a sectional view illustrating a lifting pump according to another embodiment of the present invention.

[0038]As illustrated, a lifting pump of the present invention includes:

[0039]a cylindrical body 1 that is sealed at upper and lower portions thereof by a semi-spherical upper cap 11 having a fluid outflow port 111, which is connected with a marine mining ship through a lifting pipe, and a cable insertion tube 112, and by a semi-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com