Environment-friendly golf ball

a golf ball and dissolving technology, applied in the field of dissolving materials, can solve the problems of not being able to locate and collect all lost golf balls, becoming a burden on the environment, and not being able to find and collect lost golf balls after hitting them ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

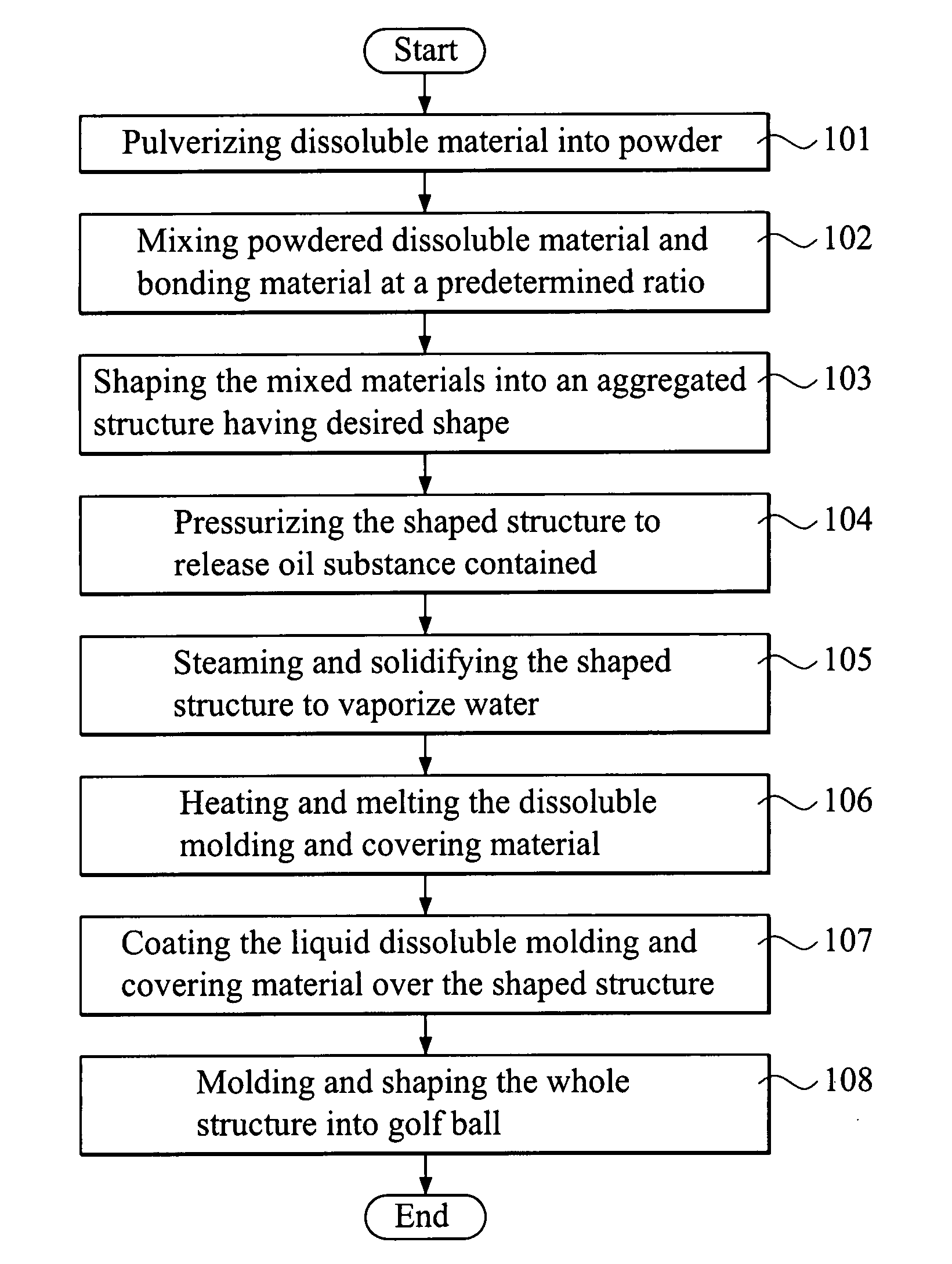

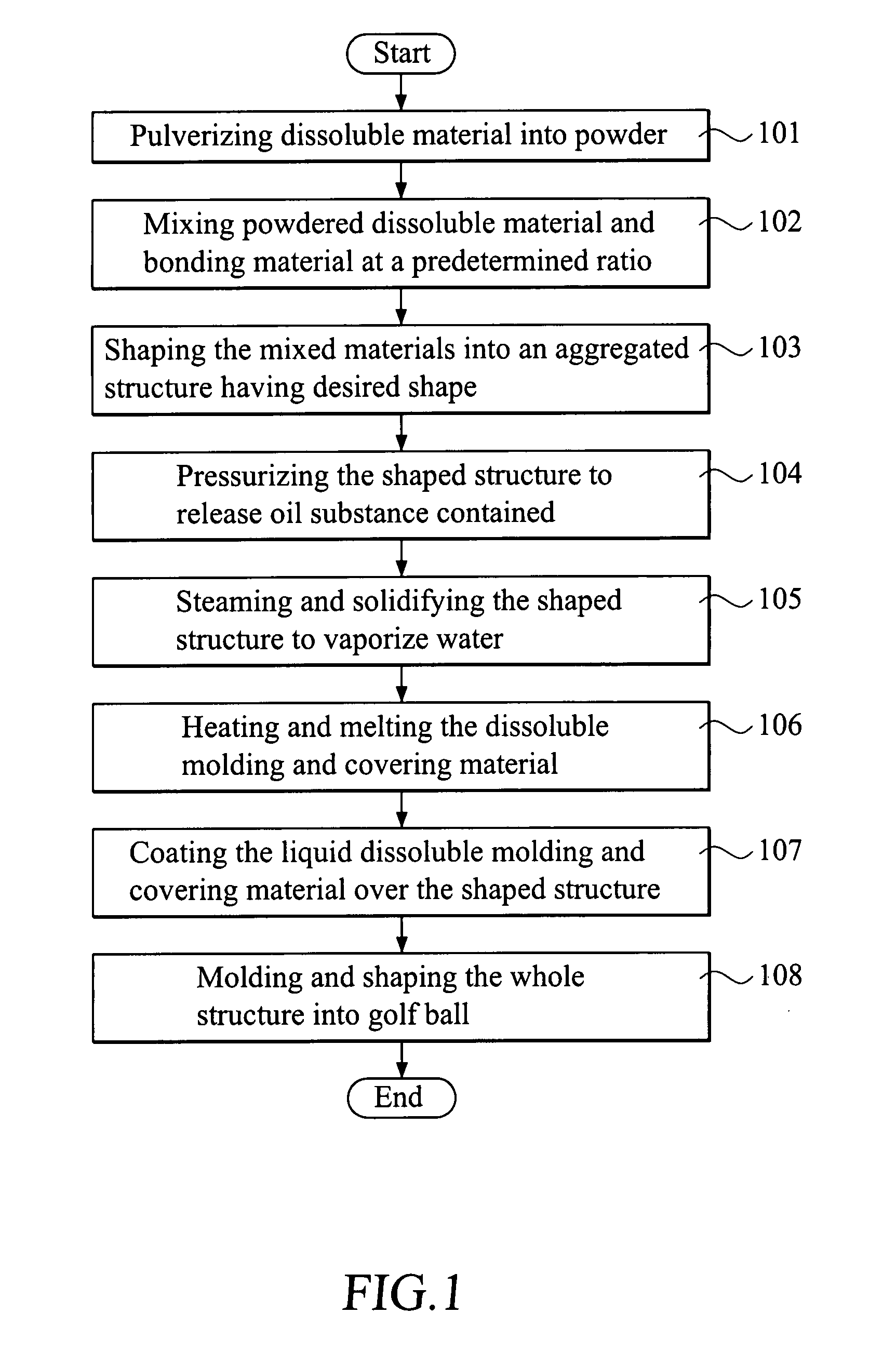

[0020]Please refer to FIG. 1 that is a flow chart showing the steps for forming an environment-friendly golf ball according to the present invention. As shown, a dissoluble material is pulverized into powder (Step 101), and a bonding material is mixed with the powdered dissoluble material at a predetermined ratio (Step 102). The mixed materials are shaped into an aggregated structure having a desired shape (Step 103). The mixed, aggregated, and shaped material is pressurized, so that oil contained in the material, e.g. soybean oil, is released therefrom (Step 104). Thereafter, the shaped structure is subjected to steaming and then allowed to solidify, so that water contained in the shaped structure is vaporized (Step 105).

[0021]Then, a dissoluble molding and covering material is heated and melted to liquid state (Step 106), which is coated to the surface of the shaped structure obtained in step 105 (Step 107). The shaped material coated with the dissoluble molding and covering mater...

second embodiment

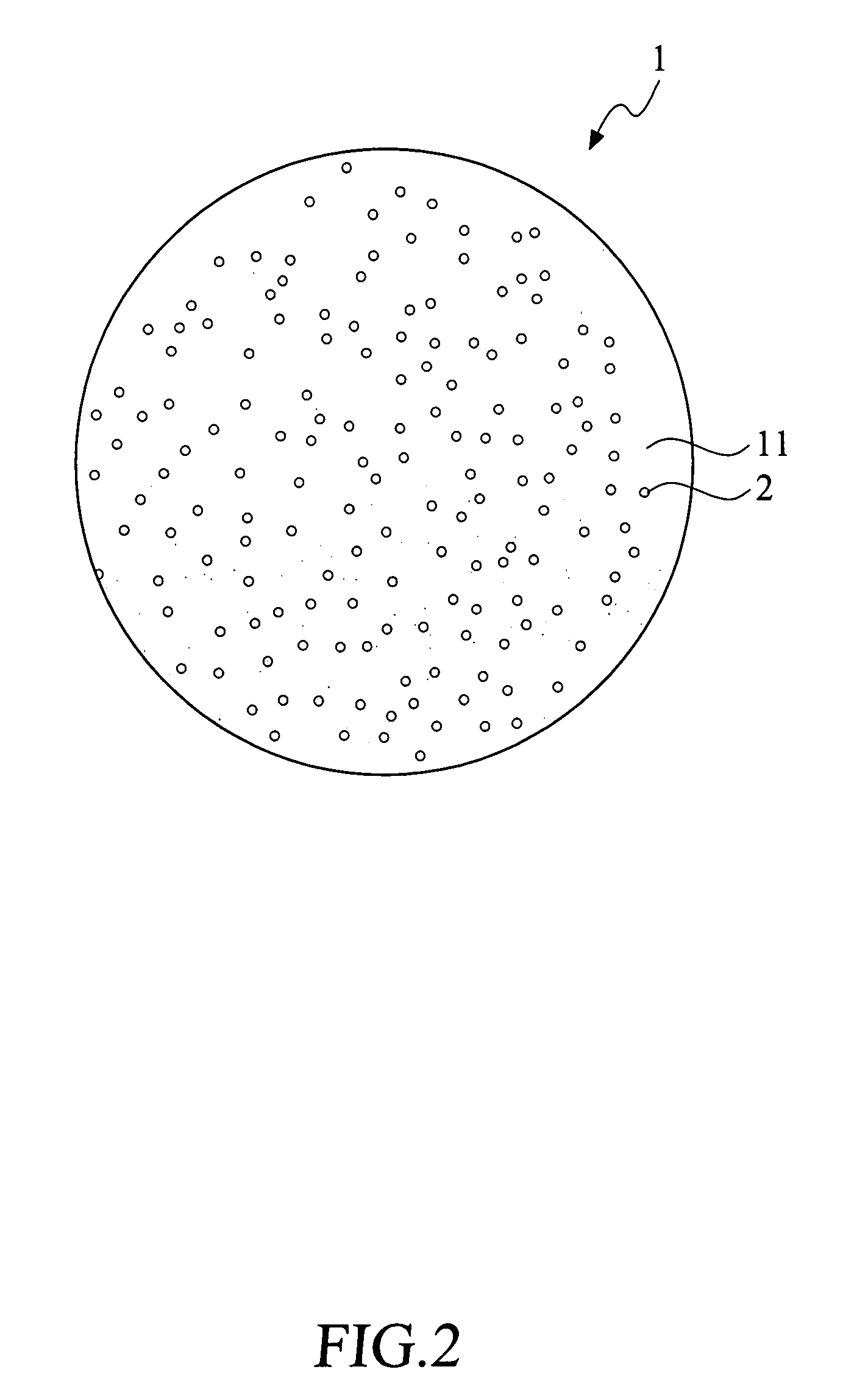

[0026]Please refer to FIGS. 5 and 6. FIG. 5 is an exploded sectional view of an environment-friendly golf ball according to the present invention and FIG. 6 is a flow chart showing the steps for forming the environment-friendly golf ball. The environment-friendly golf ball according to another embodiment of the present invention is formed through the following steps. First, a dissoluble material 11 is pulverized into powder (Step 201), and a bonding material 2 is mixed with the powdered dissoluble material 11 at a predetermined ratio (Step 202). The mixed materials are shaped into an aggregated structure having a desired shape (Step 203). The mixed, aggregated, and shaped material is pressurized, so that oil substance contained in the material is released therefrom (Step 204). Thereafter, the shaped structure is subjected to steaming and then allowed to solidify, so that water contained in the shaped structure is vaporized to form the core body 1 (Step 205).

[0027]Then, a dissoluble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com