Vehicle power unit with improved lubrication oil recovery structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

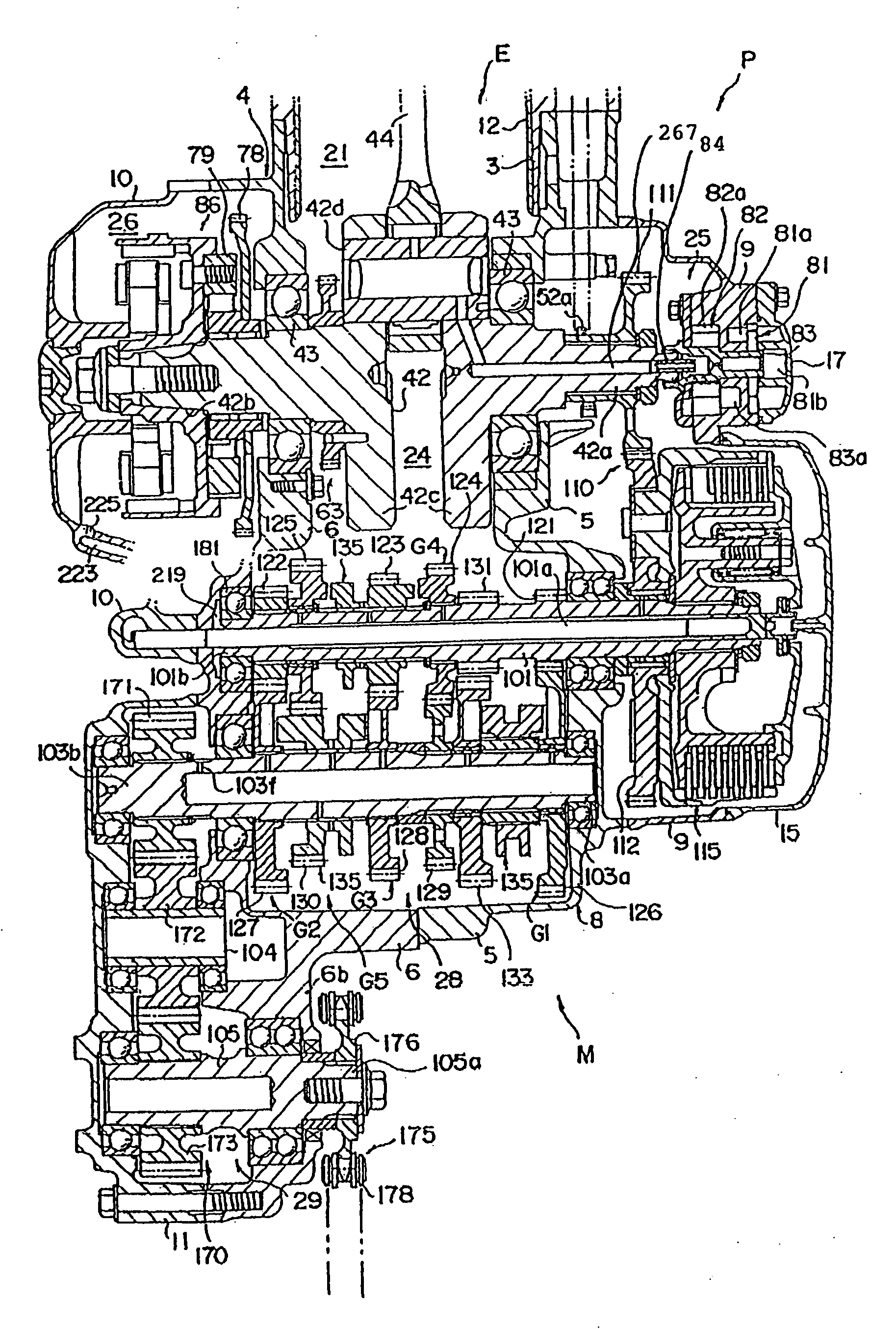

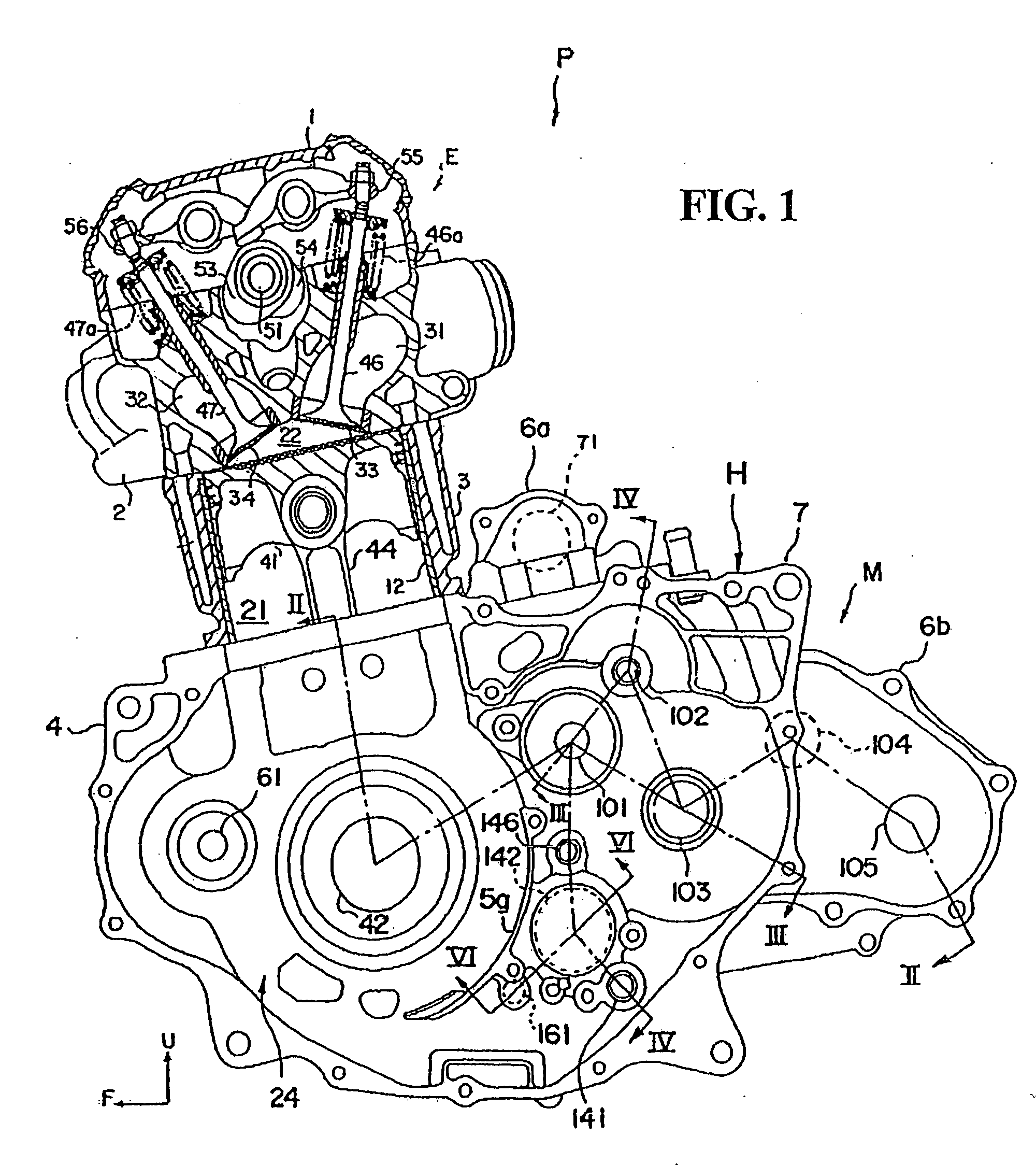

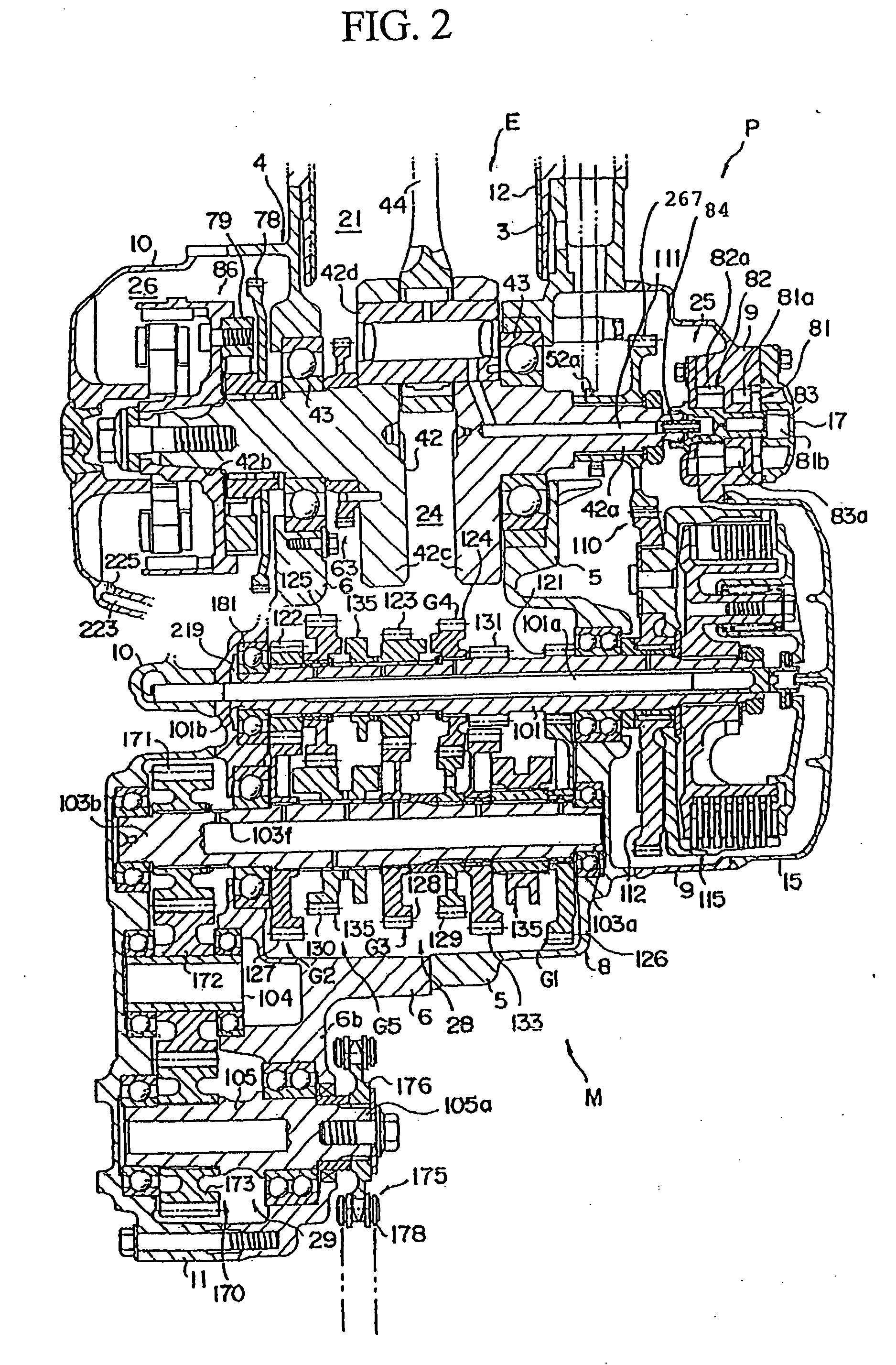

[0032]Selected illustrative embodiments of the invention will now be described in some detail, with reference to the drawings. It should be understood that only structures considered necessary for clarifying the present invention are described herein. Other conventional structures, and those of ancillary and auxiliary components of the system, are assumed to be known and understood by those skilled in the art. In the figures, arrows U and F denote the upper side and front, respectively, and references to left and right directions are made with respect to the front.

[0033]FIG. 1 is a cross-sectional view of a power unit P of a saddle-ride type vehicle as viewed from the left side, the power unit being provided with a lubricating device according to the present invention. Saddle-type vehicles are characterized by a seat which is straddled by the vehicle operator. Examples of saddle-ride type vehicles include, but are not limited to, four-wheeled all-terrain vehicles, motorcycles, and j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com