Phase angle detection apparatus and variable valve timing control apparatus using the phase angle detection apparatus for internal combustion engine

a phase angle detection and control apparatus technology, applied in mechanical devices, machines/engines, valve arrangements, etc., can solve the problems of difficult to precisely execute the phase control by only the cam angle and crank angle sensors, and difficult to detect the relative rotational phase difference by the cam angle sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

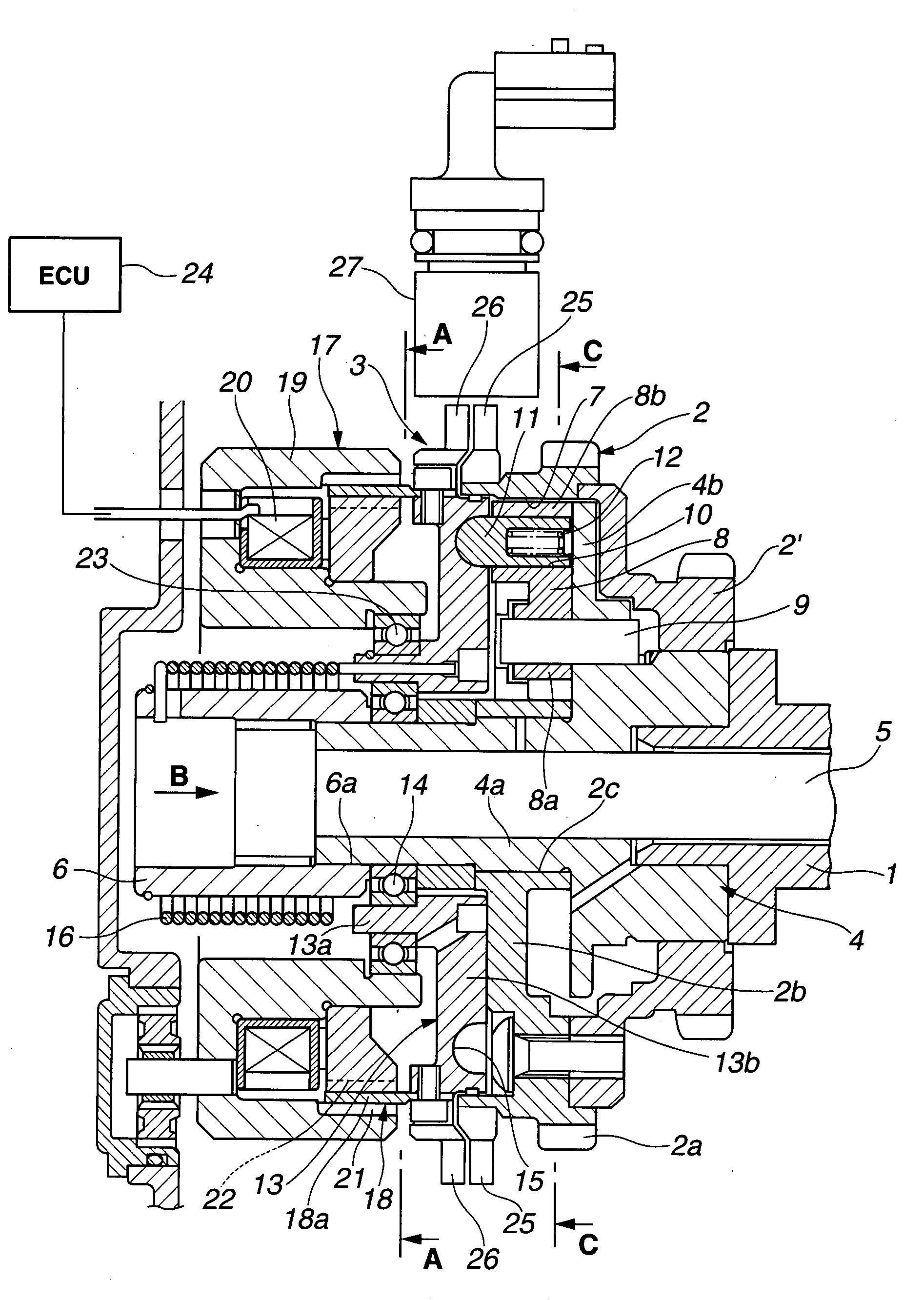

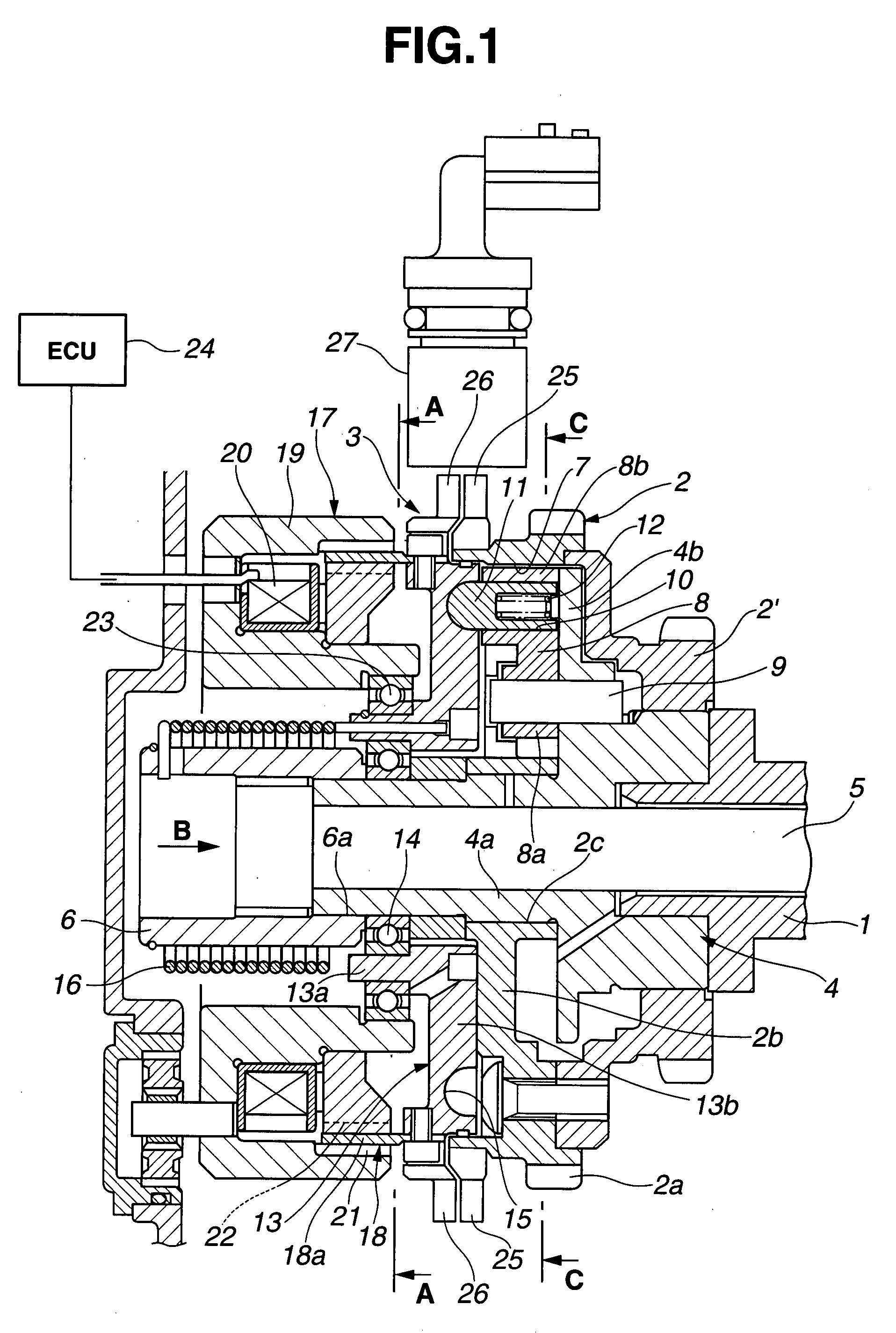

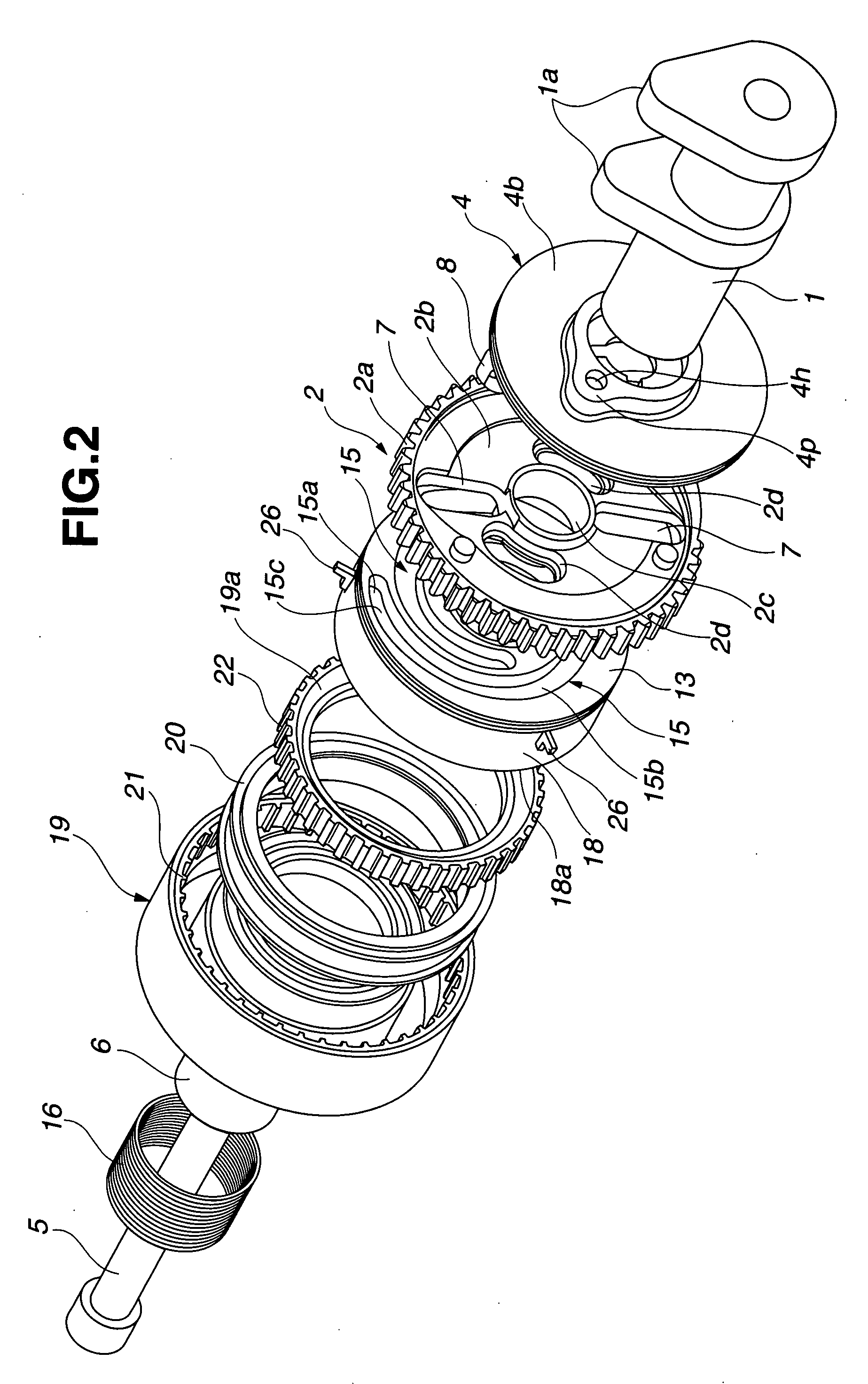

[0029]Embodiments of a phase angle detection apparatus applied to a variable valve timing control apparatus of an internal combustion engine will be explained below with reference to the drawings. In the following description, the terms “front” and “rear” are used for purposes of locating one element relative to another and are not to be construed as limiting terms. And in FIGS. 2 and 3, “front side” is a side of a torsion spring 16 (described later), and “rear side” is a side of a cam 1a (also described later). Further, although each embodiment below is applied to control of open / close timing of an intake valve for the internal combustion engine, it can also be applied to control of open / close timing of an exhaust valve.

[0030]Firstly, the variable valve timing control apparatus using the phase angle detection apparatus will be explained with reference to FIGS. 1 to 9. The variable valve timing control apparatus includes a camshaft 1 rotatably supported on a cylinder head (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com