Fence

a technology of fences and pillars, applied in the field of fences, can solve the problems of rot or deterioration affecting the appearance of conventional wooden fences, and requiring periodic maintenance, so as to increase the strength and/or rigidity of components, facilitate rapid and easy construction, and facilitate formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

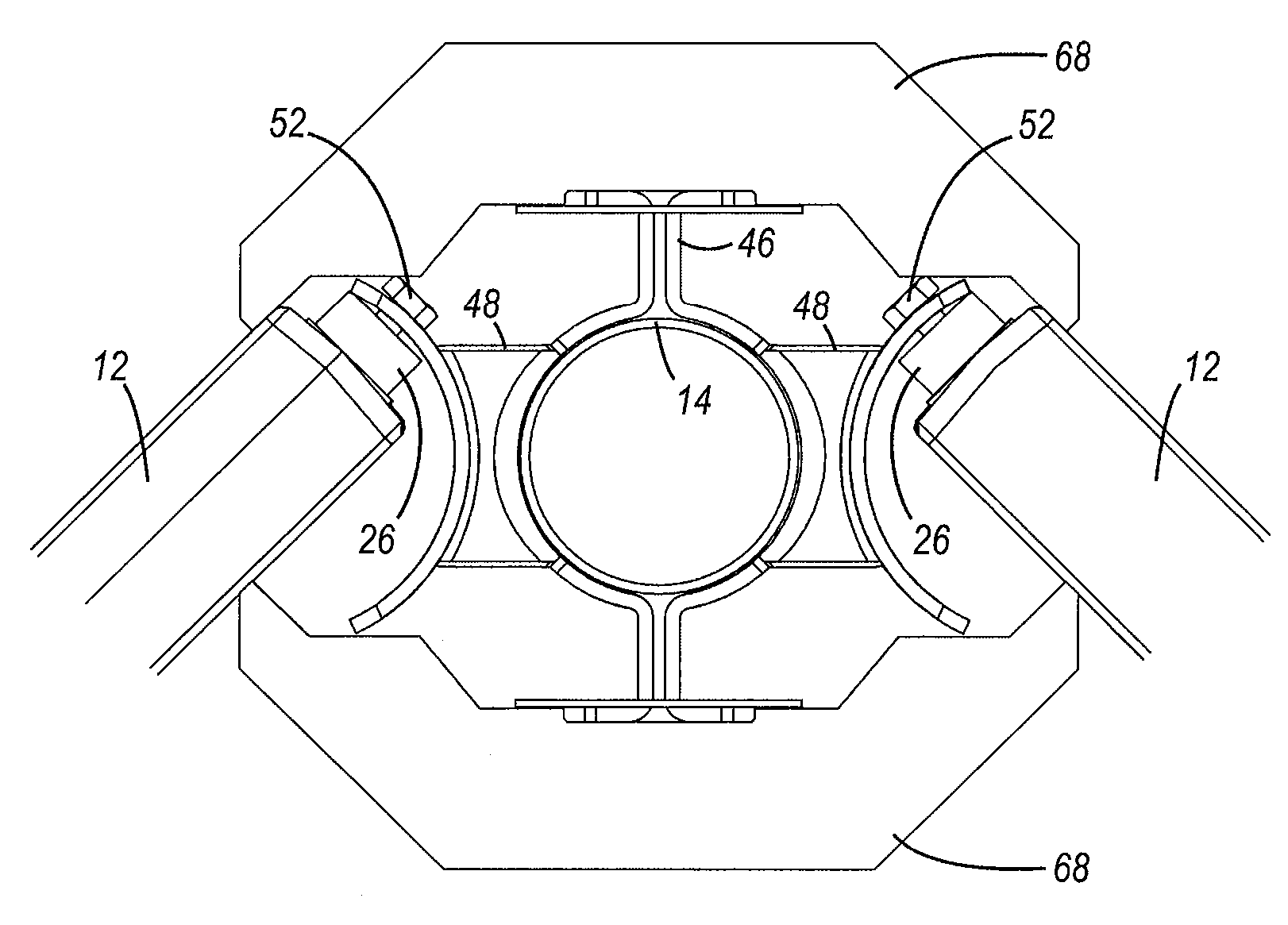

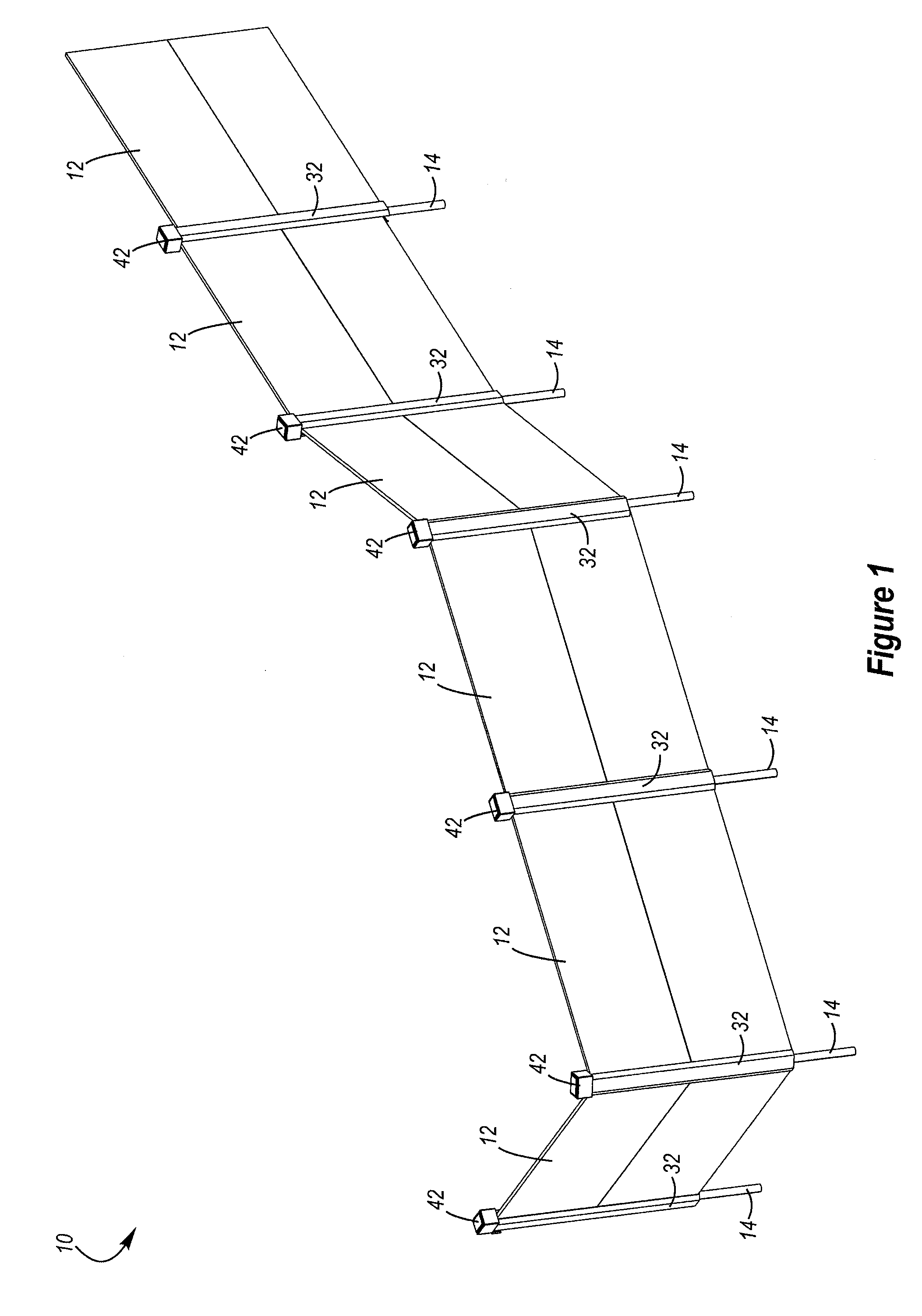

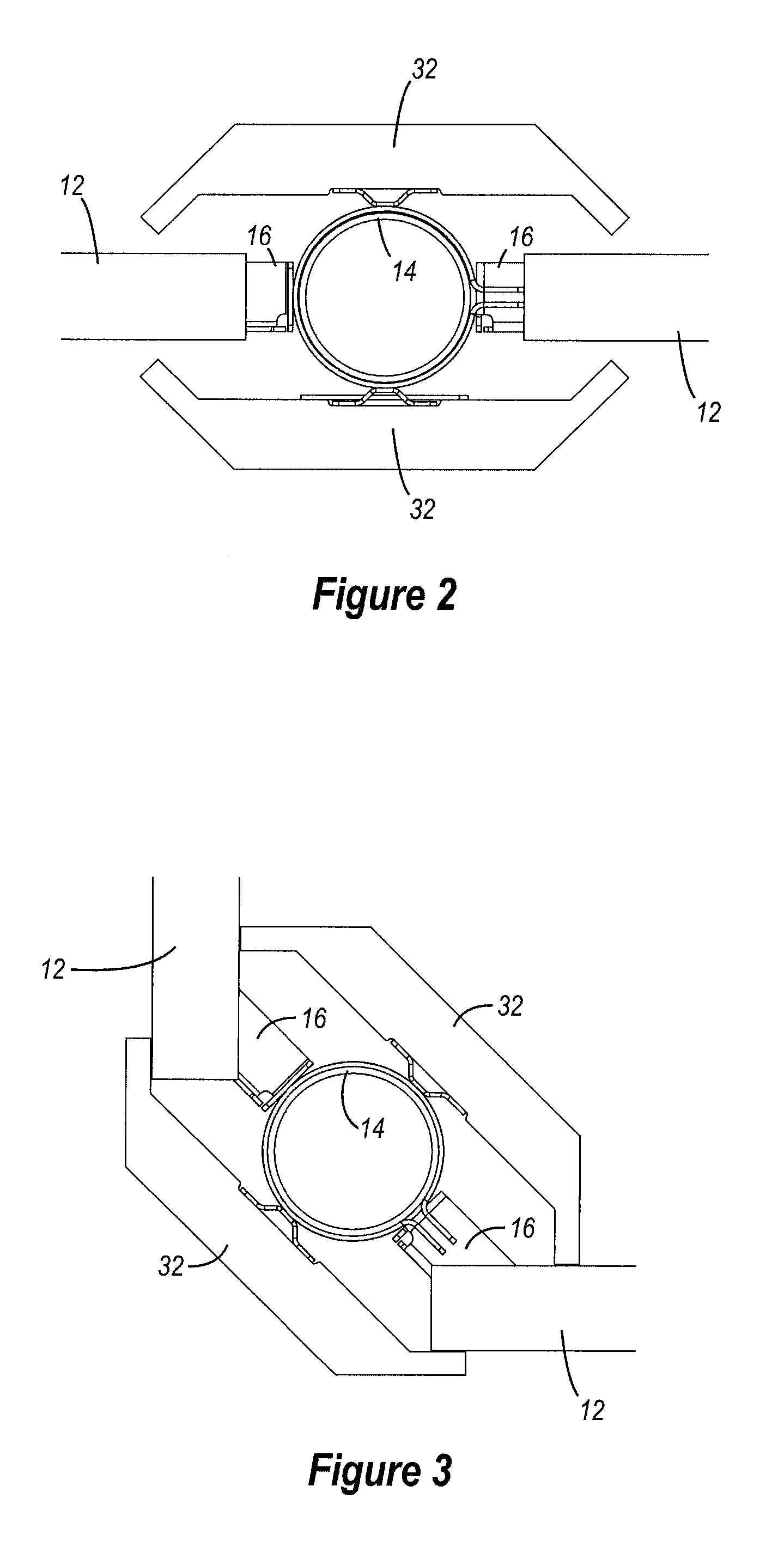

Image

Examples

Embodiment Construction

[0010] A need therefore exists for a fence that eliminates or diminishes the above-described disadvantages and problems.

[0011] One aspect is a fence that may be constructed from relatively lightweight materials. For example, all or a portion of the fence may be constructed from plastic. Advantageously, the lightweight materials may allow the fence to be easily moved and transported. The lightweight materials may also allow the fence to be easily installed and removed.

[0012] Another aspect is a fence that may be constructed from blow-molded plastic. Advantageously, the fence may contain hollow interior portions that are formed during the blow-molding process, which may allow a light-weight fence to be constructed. In addition, if the fence is constructed from blow-molded plastic, then the blow-molded plastic portions may be relatively easily formed into many different desired shapes, sizes, configurations and designs depending, for example, upon the intended use and / or configuratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com