Support frame for use with lawn and refuse bags

a technology for supporting frames and refuse bags, which is applied in the direction of sports equipment, domestic objects, packaging goods, etc., to achieve the effects of high strength-to-weight ratio, increased bag engagement area, and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

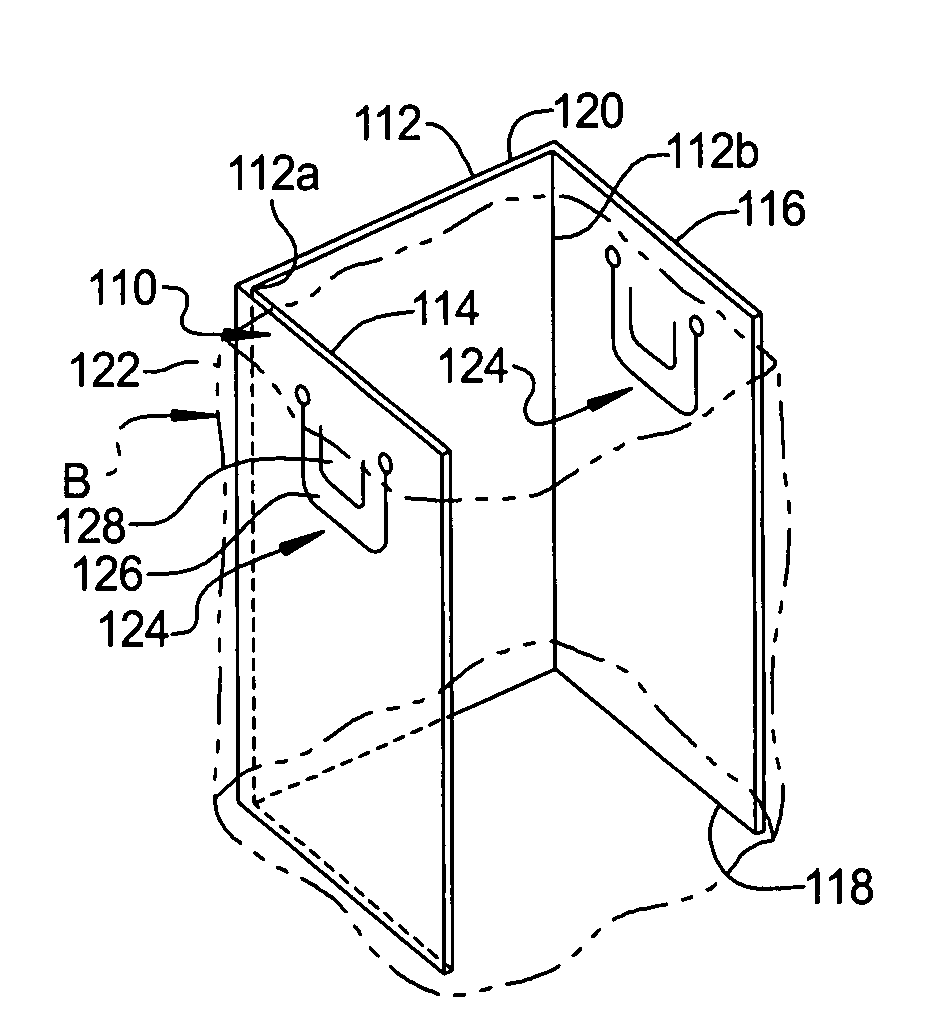

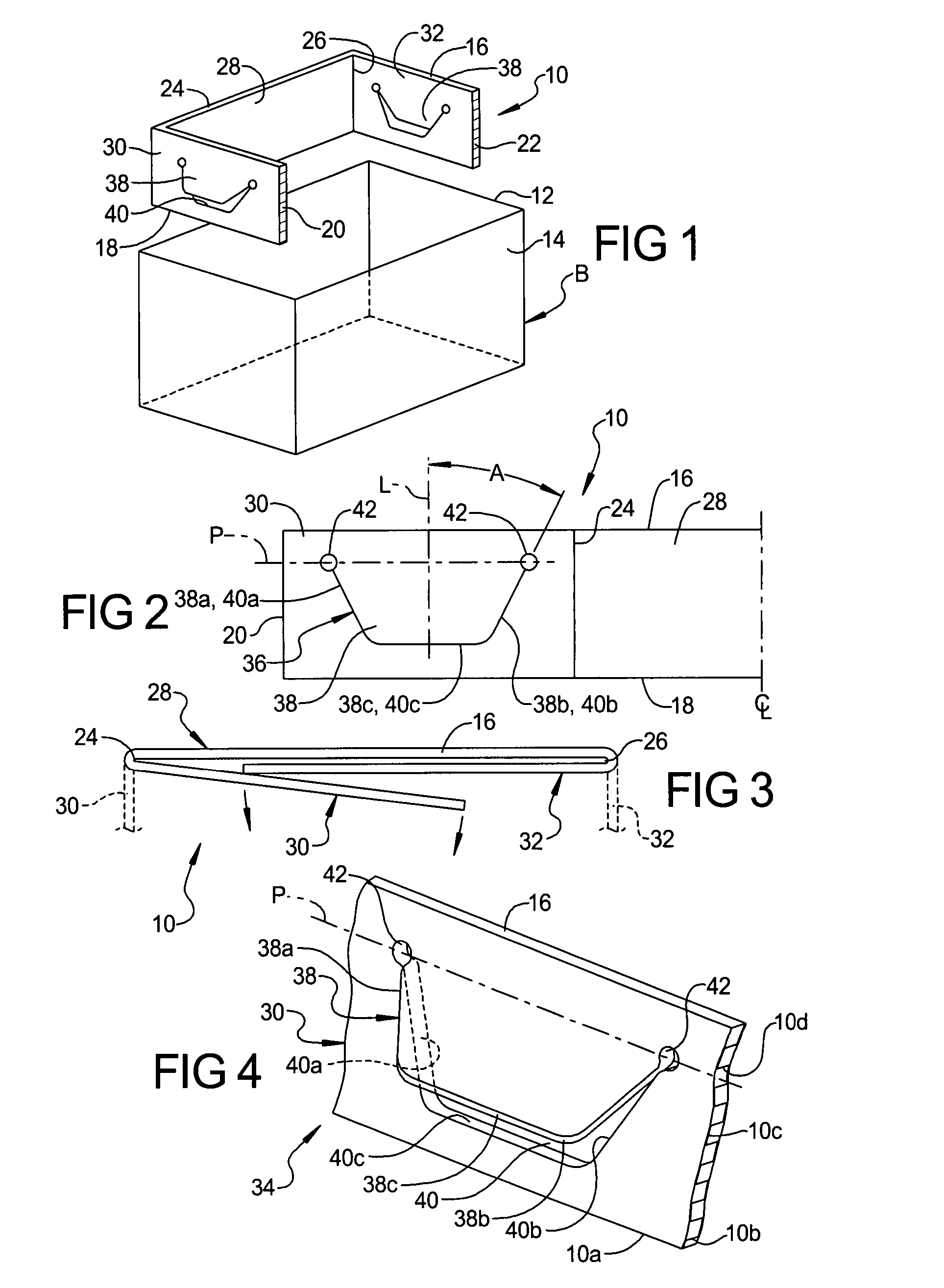

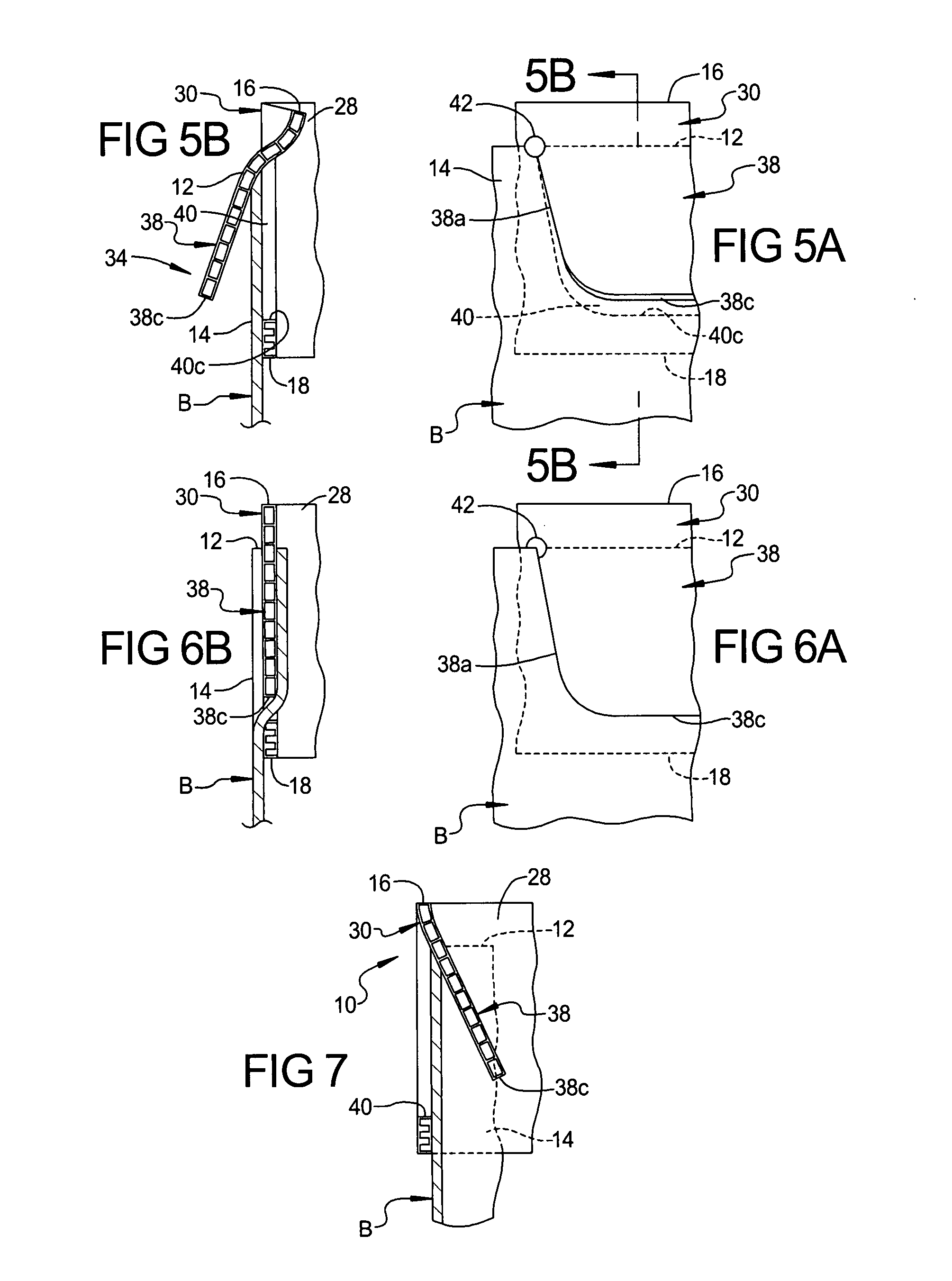

[0045] Referring now to the drawings, there is illustrated embodiments of a bag support or retention frame according to this invention. In a first arrangement, a support frame is fittable atop a self-standing generally rectangularly open paper lawn bag. In another arrangement, a support frame is adapted to be fittable within in a paper or non-self standing plastic bag and extend from the top to the bottom thereof

[0046] According to the first arrangement, FIG. 1 illustrates a bag support or retention frame according to this present invention, generally indicated by the reference number 10 positioned atop a top end 12 of and insertion, at least in part, into the upper end portion 14 of a lawn and refuse bag or the like, generally indicated at “B”. The upper end portion 14 of the bag “B” is openable and typically forms a rectangular shaped entryway into the interior of the bag.

[0047] Generally, the bag “B” is conventionally available in the marketplace and is comprised of a material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com