Three Axis Aerodynamic Control of Guided Munitions

a technology of guided munitions and control systems, applied in the field of armaments, can solve the problems of low accuracy, unguided munitions are subject to aim errors, wind disturbances, etc., and achieve the effect of improving system accuracy and improving aerodynamic maneuvering performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

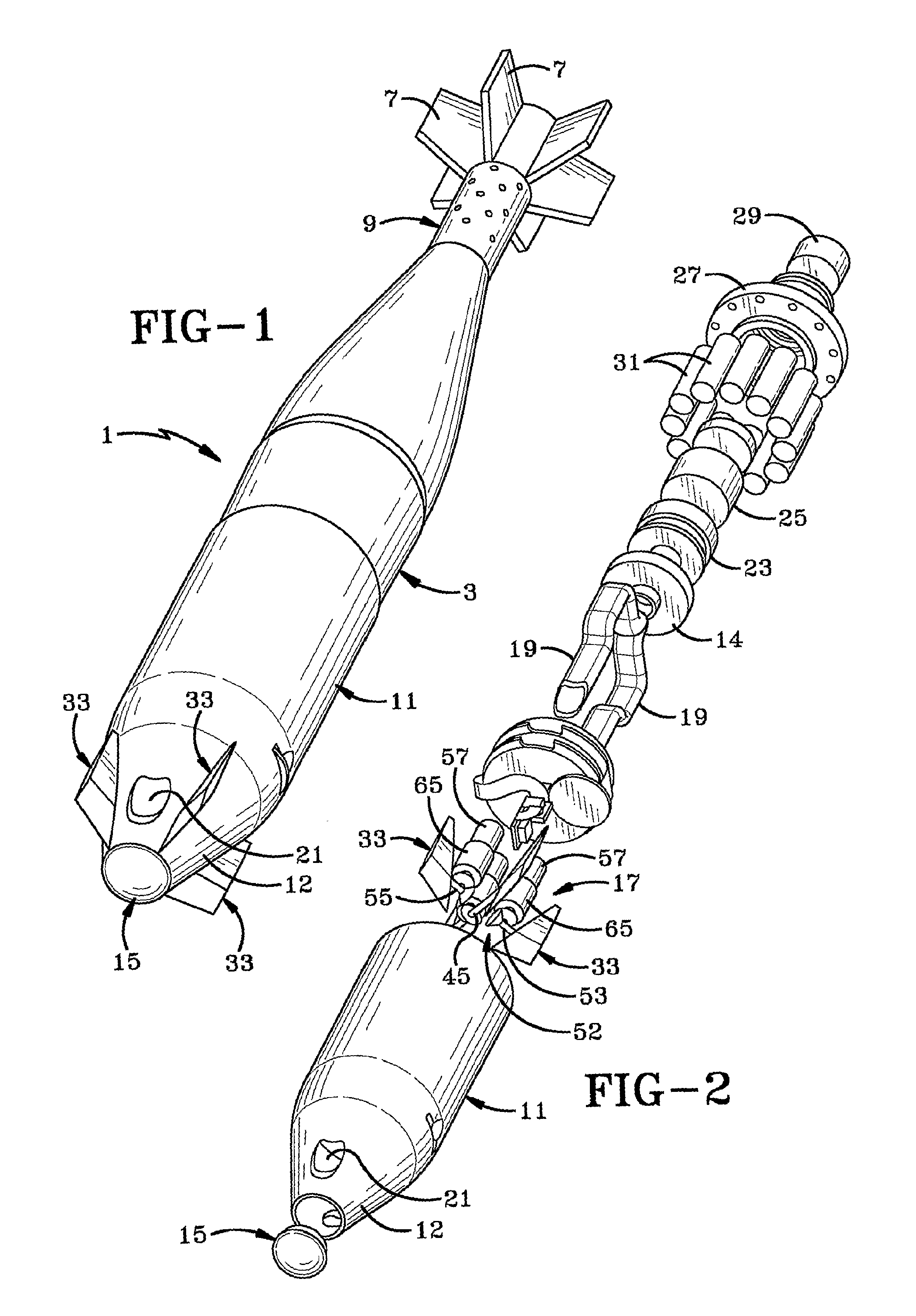

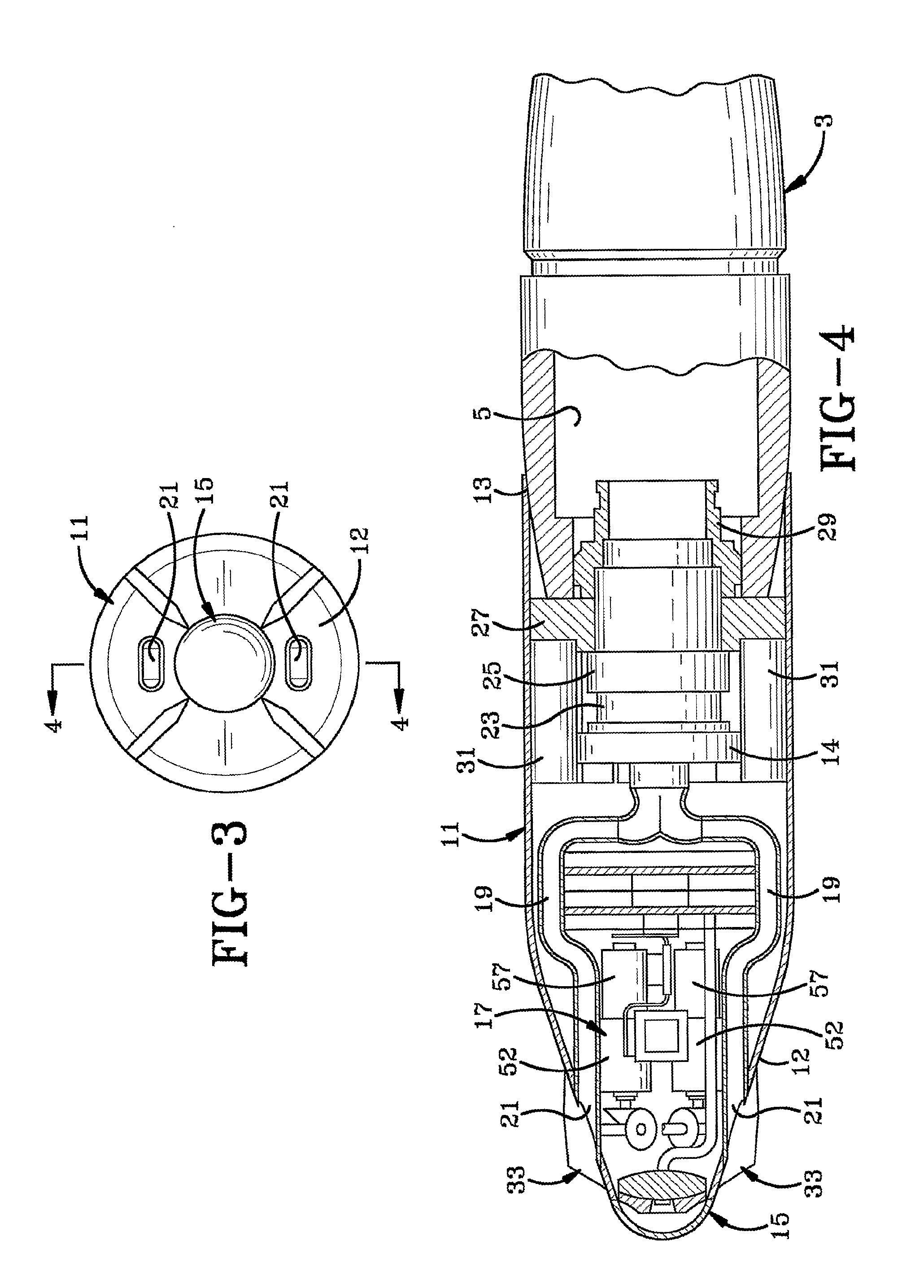

first embodiment

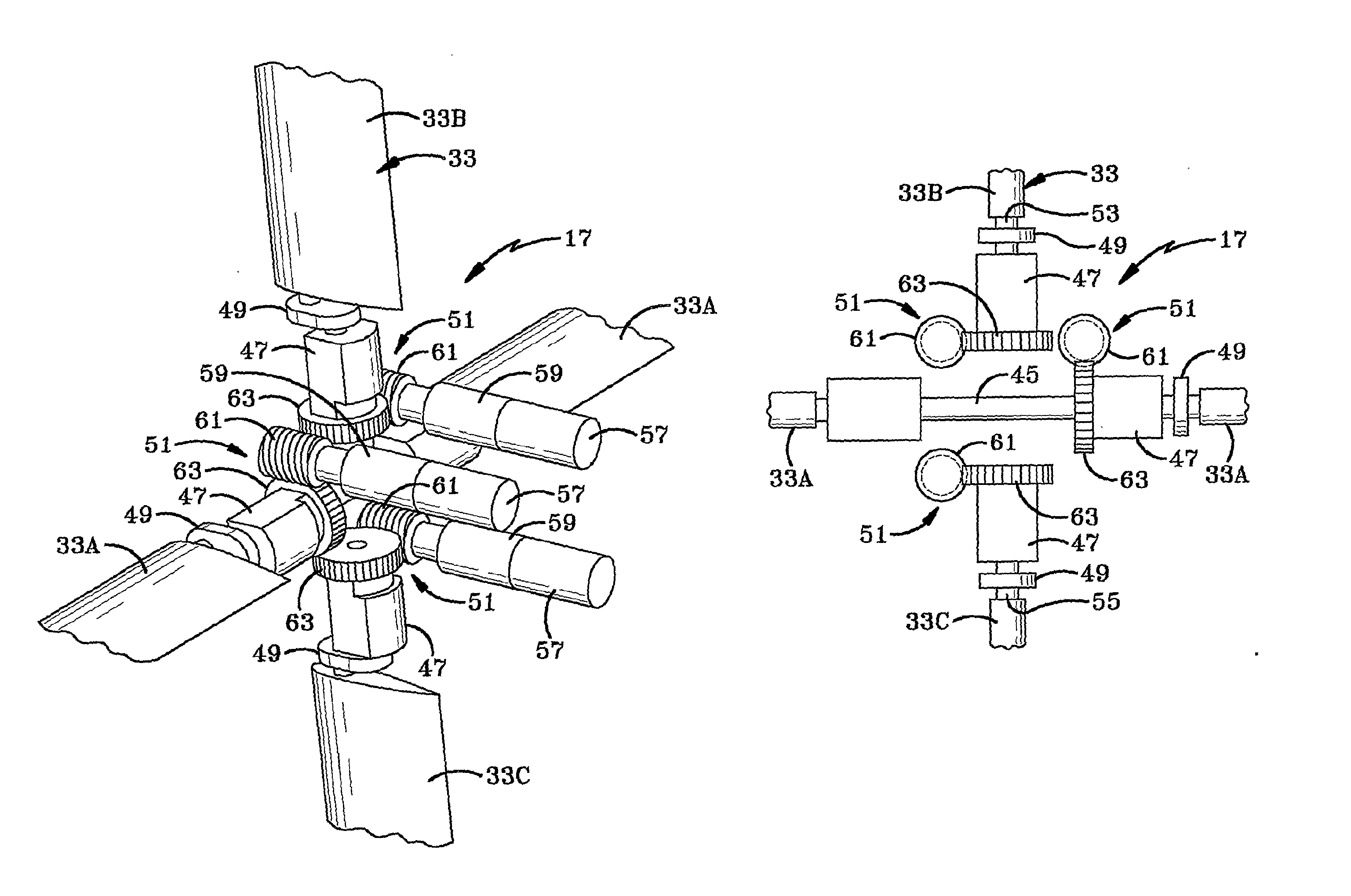

[0032] the three axis control system 17 is shown in detail in FIGS. 6 and 6A. System 17 includes four canards 33, an example of which is shown in FIGS. 5 and 5A. Canards 33 preferably are identical or very similar to each other, each having a double wedge configuration consisting of a first wedge 35 and a second wedge 37. Each wedge is formed with symmetrical opposed surfaces which taper inwardly outwardly from a junction 41 in which is located a pivot 43. The junction 41 and pivot 43 are located at the thickest portion of the canard which also is the longitudinal center of pressure of the canard, which provides for torque balanced aerodynamic surfaces for the canard.

[0033] Referring to FIGS. 6 and 6A, two of the canards indicated at 33A, are connected to a common shaft 45, each through a wing pivot lock 47 and a wing fold pivot 49. Lock 47 and pivot 49 enable the canard to be retracted against nose 11 enabling certain munitions to be launched from a mortar launcher, afterwhich the ...

second embodiment

[0036] In a second embodiment as shown in FIGS. 7, 7A and 7B, a modified gear assembly indicated generally at 52, includes stepper motors 57 which are connected to the respective canard shafts through a spur reduction gear 65 or 65A, each preferably having a 30 / 1 zero backlash reduction drive. The spur reduction gears in turn are connected to a first bevel gear 67 which engages and drives a second bevel gear 68 attached to a respective one of the canard shafts.

[0037] Thus, drive motors 57, which preferably are stepper motors, can be connected by various gear assemblies, such as gear assemblies 51 and 52 to the canards, which if desired will be through a pivot lock 47 and fold pivot 49, and in another embodiment directly to the canards. In either construction the gear assemblies and drive motors will rotate the canards about their pivots 43 to control the pitch, roll and yaw movement of the munition body after passing through apogee and in its descent toward a target along a ballisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com