Inductor topologies with substantial common-mode and differential-mode inductance

a topology and differential mode technology, applied in the direction of inductance, continuous variable inductance/transformer, core/yokes, etc., can solve the problem that the single traditional inductor is not effective in simultaneously filtering both cm and dm noise, and achieve the effect of reducing the size, weight, and complexity of the electromagnetic interference filtering circui

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

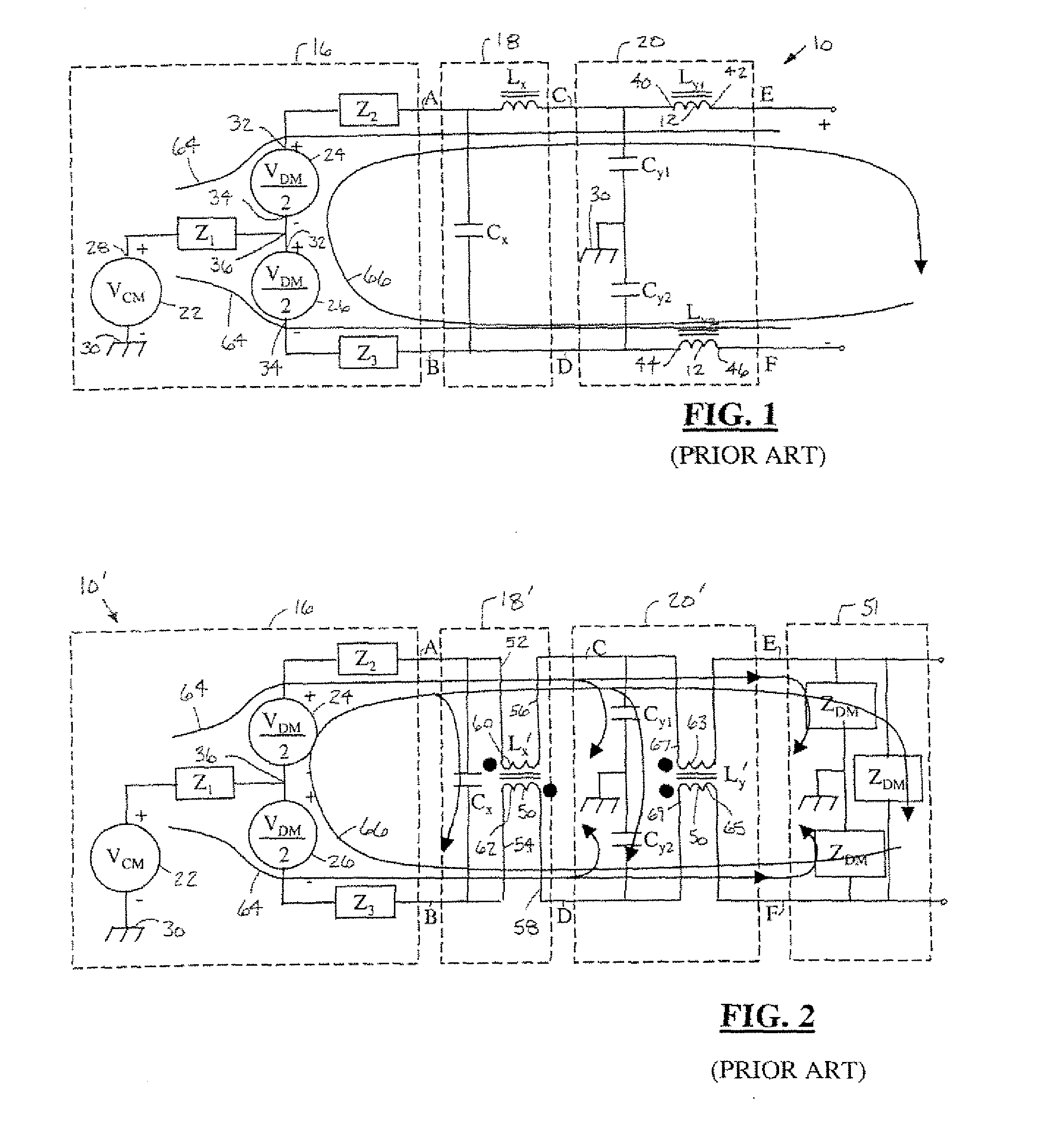

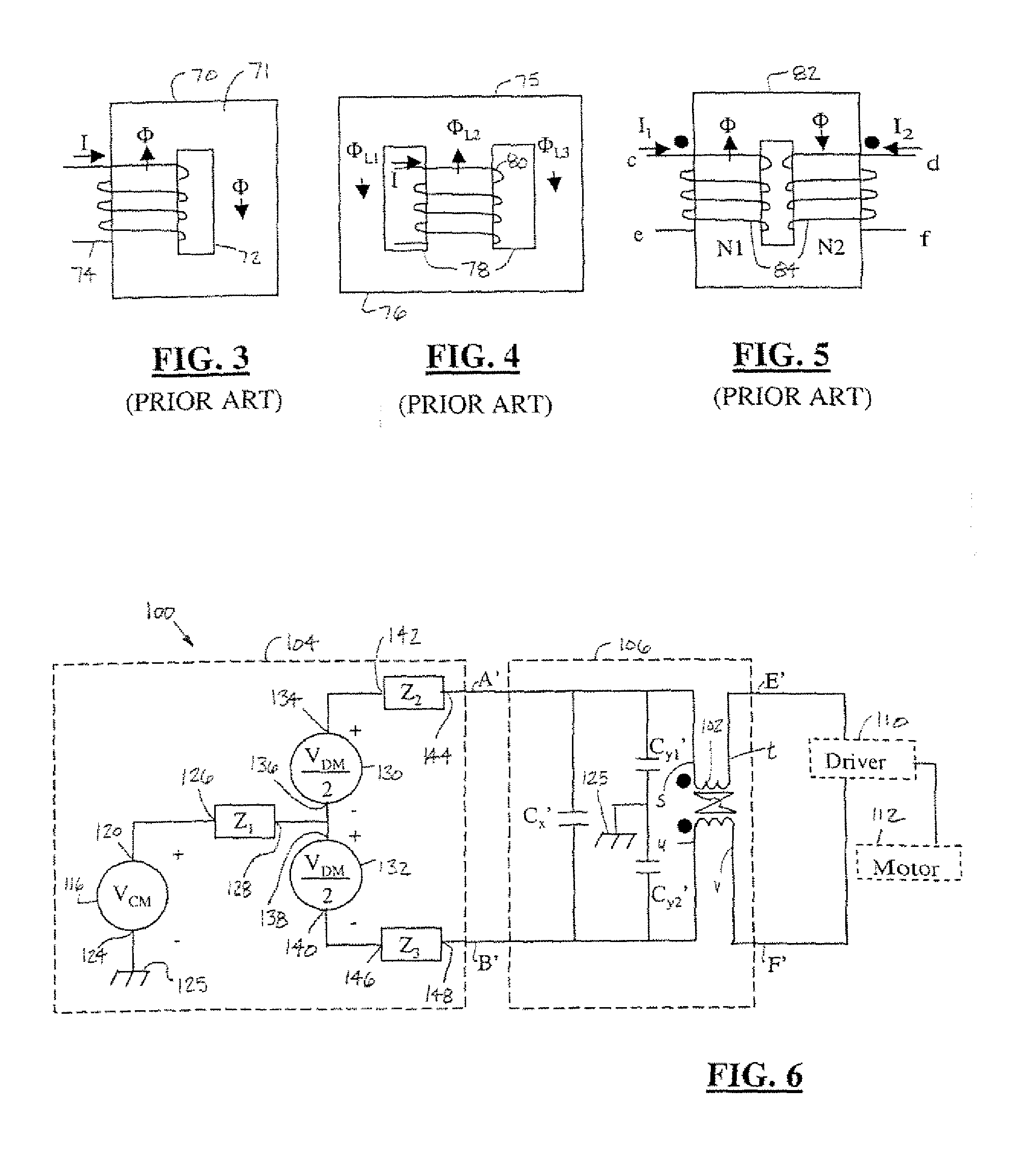

[0027]In the following described FIGS. 1 and 2 typical common mode (CM) and differential-mode (DM) filter topologies are shown for the reduction of electromagnetic interference (EMI) noise emission. FIG. 1 illustrates a simple filter topology that includes capacitors and inductors without mutually coupled windings. FIG. 2 illustrates a filter topology with inductors that have mutually coupled windings.

[0028]Referring now to FIG. 1, a schematic view of a traditional electronic circuit 10 that incorporates CM and DM filtering, with inductors 12 that have single-coupled windings, is shown. The circuit 10 includes an EMI source circuit 16 and a pair of inductor-based filtering circuits, namely, a DM filtering circuit 18, and a CM filtering circuit 20.

[0029]The EMI source circuit 16 has a CM source 22, which represents CM EMT noise generated by EMI circuit 16, and a pair of DM sources 24, 26, which represent DM EMI noise generated by EMI circuit 16. The CM source 22 has a CM terminal 28 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductive | aaaaa | aaaaa |

| magnetic internal flux | aaaaa | aaaaa |

| switching speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com