Bi-Directional Pump Mechanism for Balanced Flow Fluid Exchanger

a pump mechanism and fluid exchange technology, applied in the direction of machines/engines, liquid fuel engines, rotary/oscillating piston pump components, etc., to achieve the effect of improving the exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

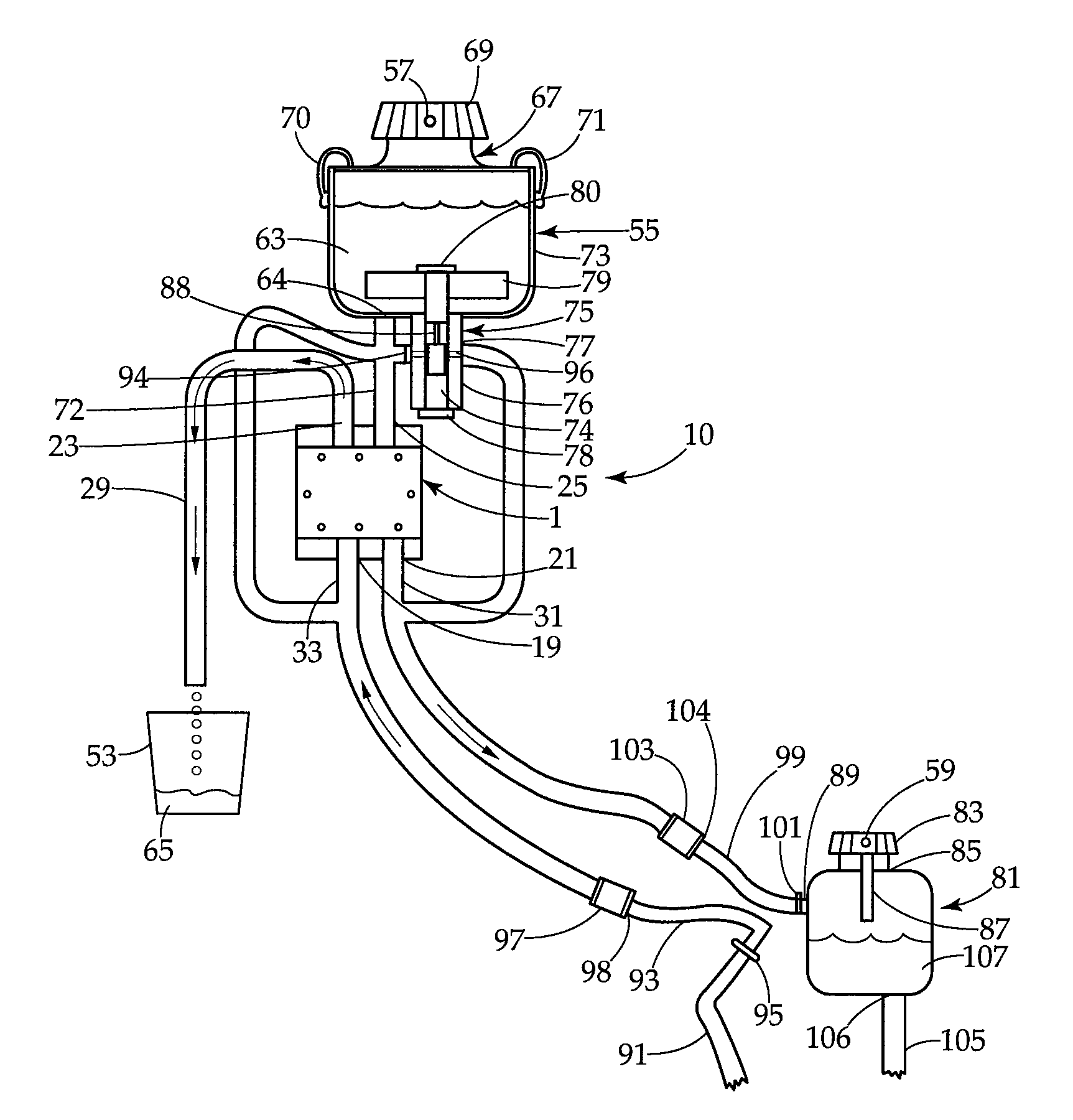

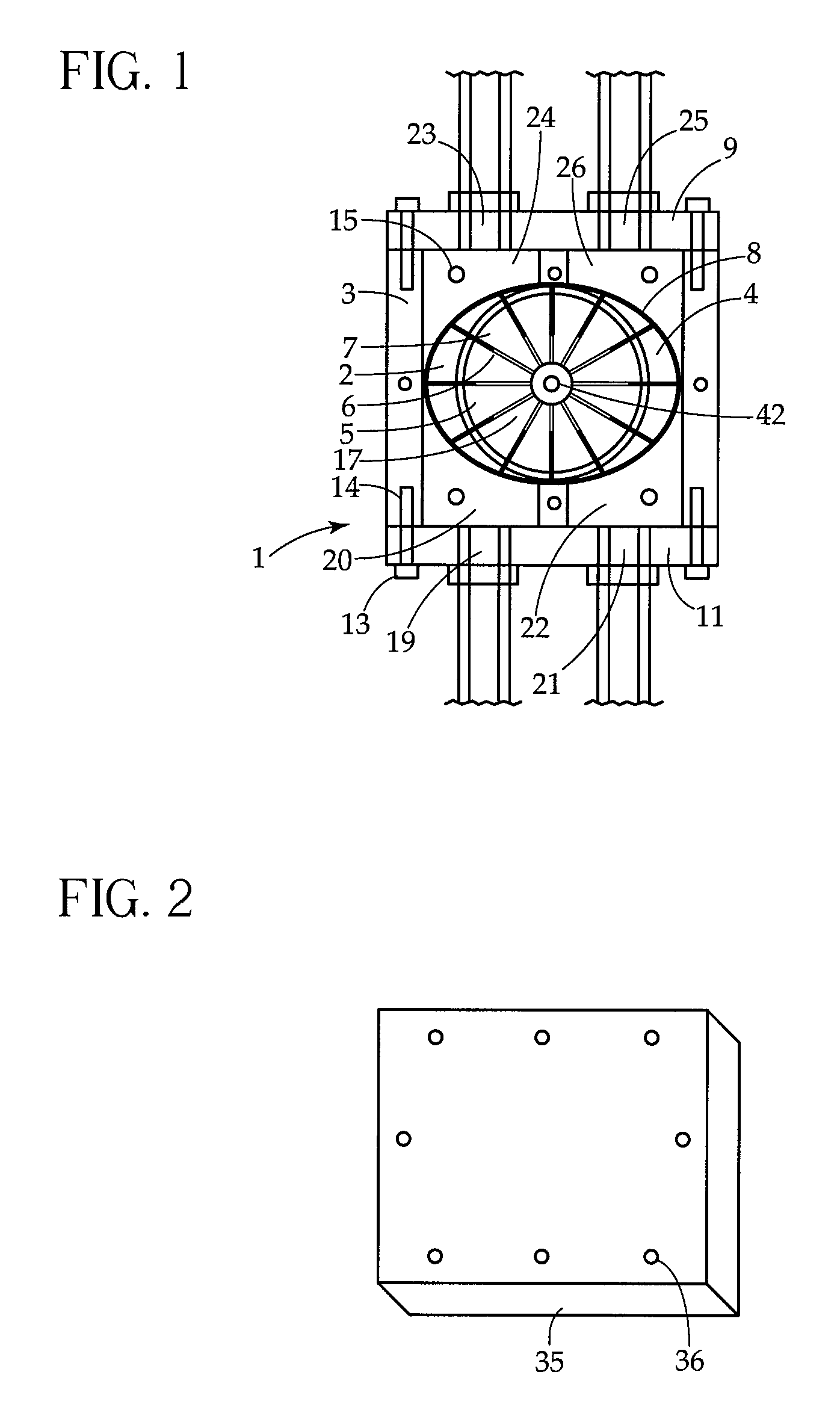

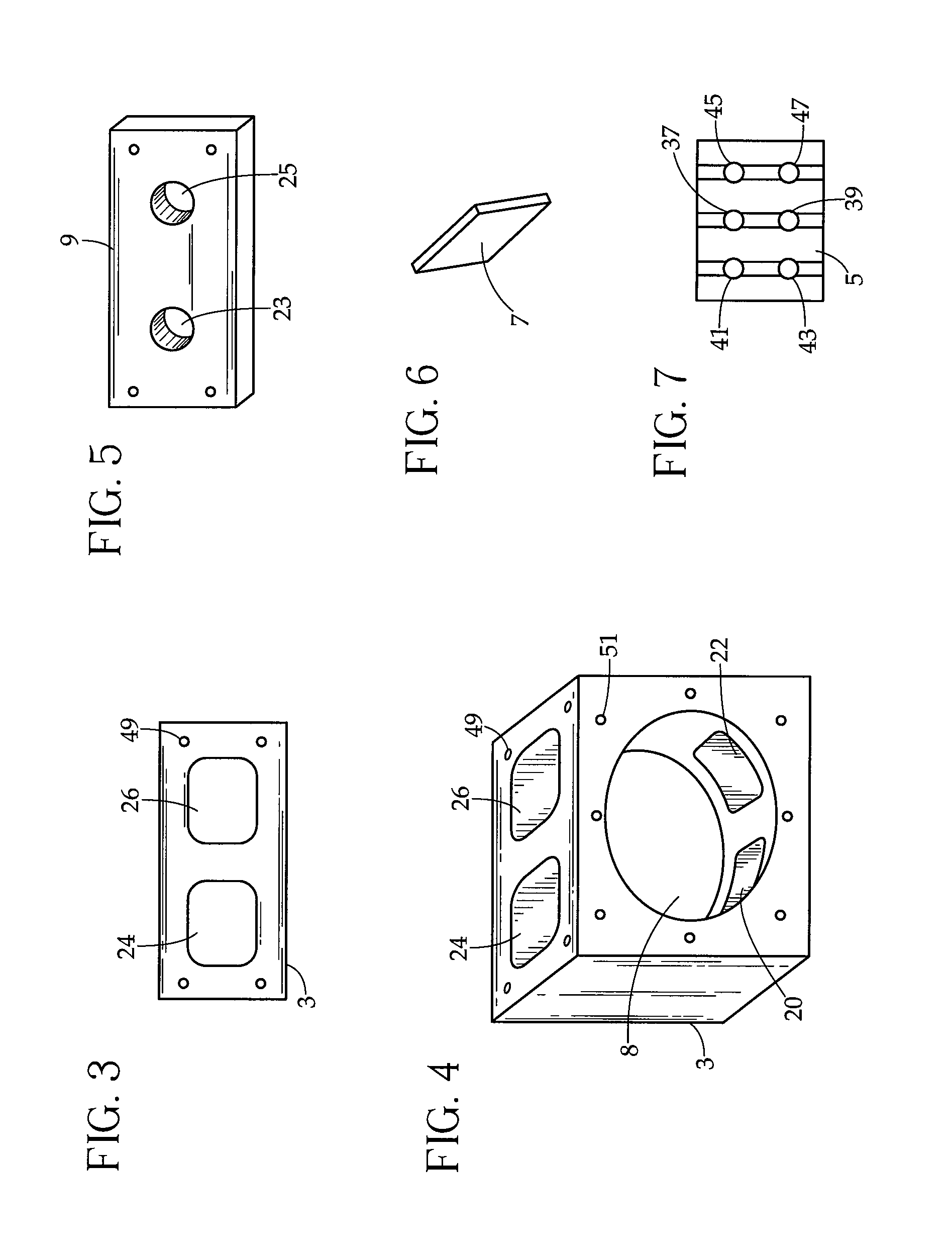

[0025]FIG. 1 is a schematic view of a fluid pump assembly 1 utilized in preferred embodiment of the present invention. Fluid pump assembly 1 provides a dual chambered vane pump with two ports per chamber. A vane holder 5 with a plurality of vanes 7 is received inside an elliptical bore 8 of a pump block 3. Pump block 3 in this instance may be molded and comprised of an acrylic type plastic compound, but can also be molded or constructed of many other materials such as various other types of plastics or hard rubber compounds, or various types of metals such as aluminum, brass or steel, or other metals, depending on the pressures, temperatures or chemical composition of the fluids being exchanged and the desired longevity of the fluid exchanger. Fluid pump assembly 1 is shown with side cover 35 removed. FIG. 2 shows side cover 35 which engages a side surface of pump block 3 upon assembly.

[0026]Vane 7 is a blade, and in this instance is constructed of an acrylic type plastic compound, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com