Disposable food packaging

a food packaging and disposable technology, applied in the direction of flexible container closure, transportation and packaging, sacks, etc., can solve the problems of product leakage, a large amount of product, and the packaging is relatively difficult to quickly insert into a crowded purse, diaper bag, backpack, etc., to minimize the risk of scratching a child, facilitate handling and use, and facilitate the effect of transportability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

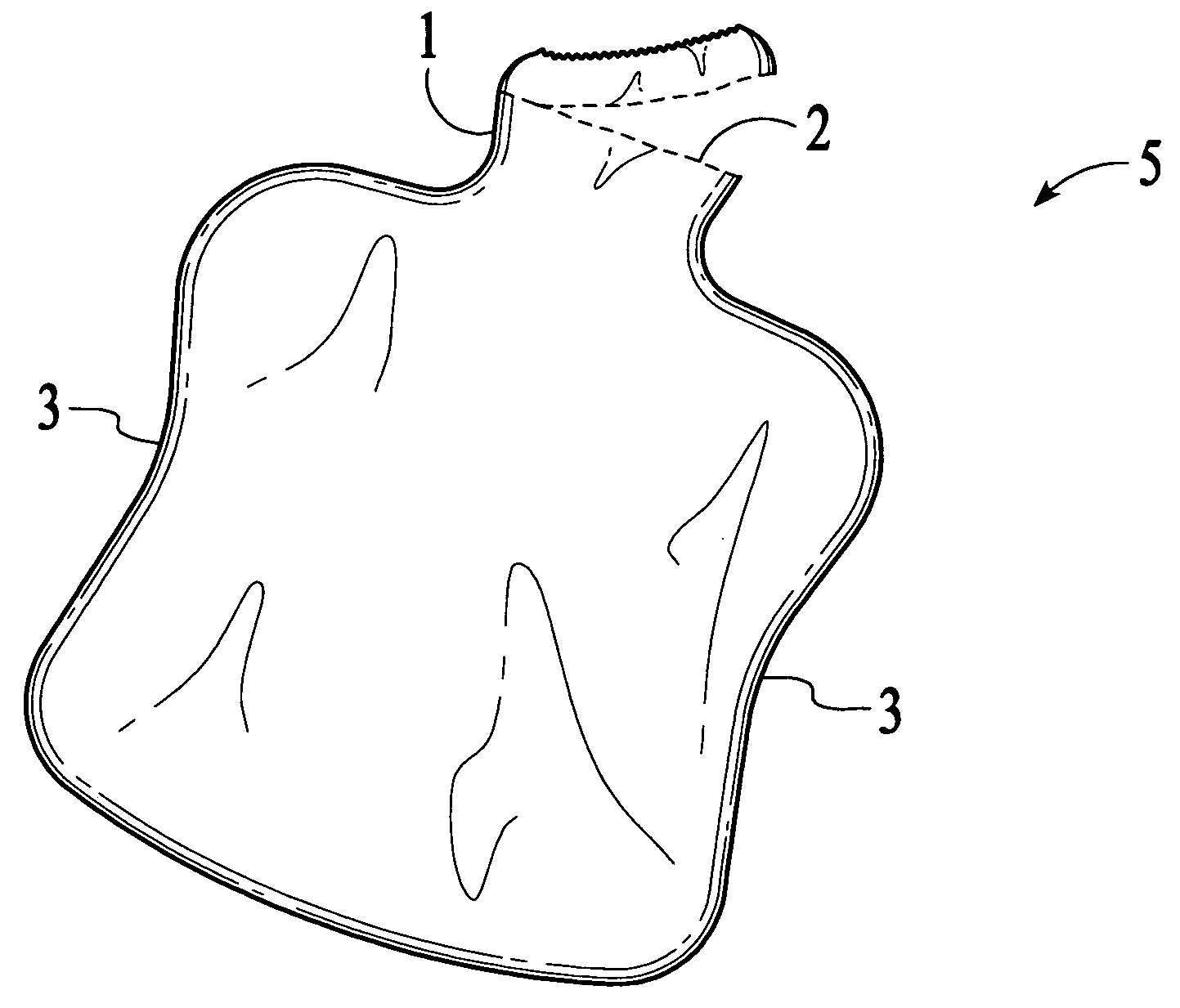

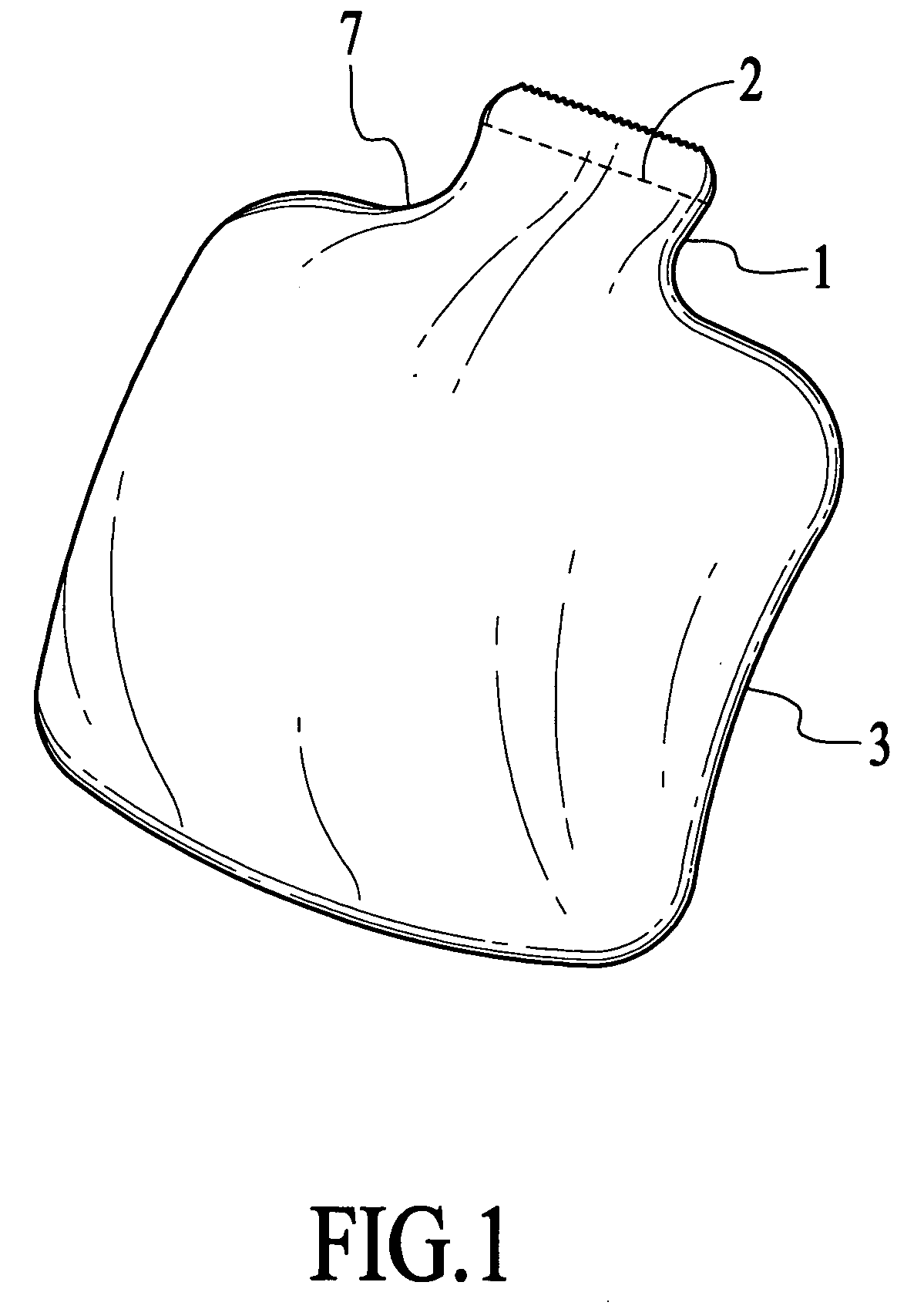

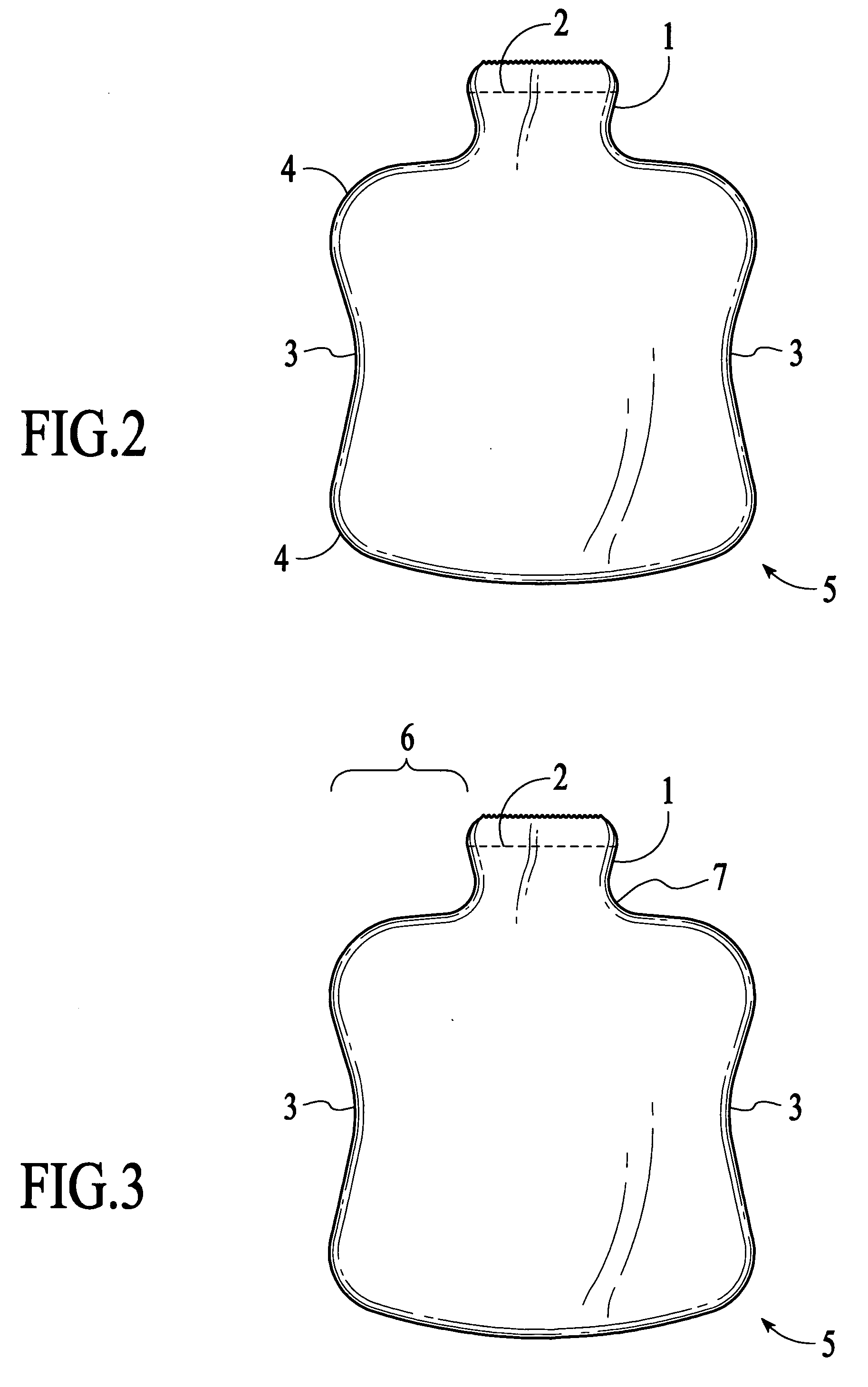

[0016]The packaging, as illustrated generally by FIG. 1, comprises an opposed first plastic layer and a second plastic layer sealed to define a package body 5 comprising an upper wall 6, a lower wall 4, and two sides 3. From package body 5, a neck 1 emanates from said upper wall 6 at bend 7. Neck 1 represents an opening from which flowable food contents substantially contained within said package body 5 may be extruded, compressed, or naturally flow from the interior of package body 5. The corners transitioning between upper wall 6, lower wall 4, sides 3, and neck 1 are rounded. Neck 1 is openably sealed, thereby completely sealing said opposed first and second plastic layers of said neck 1 when the package is in the closed state. The opposed plastic layers of neck 1 further include a tear strip 2 so that removal of at least a portion of said strip allows opening of the sealed neck permitting flowable food contents within said packaging to flow therefrom.

[0017]Referring again descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

| physical forces | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com