Roadway grinding/cutting apparatus and monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

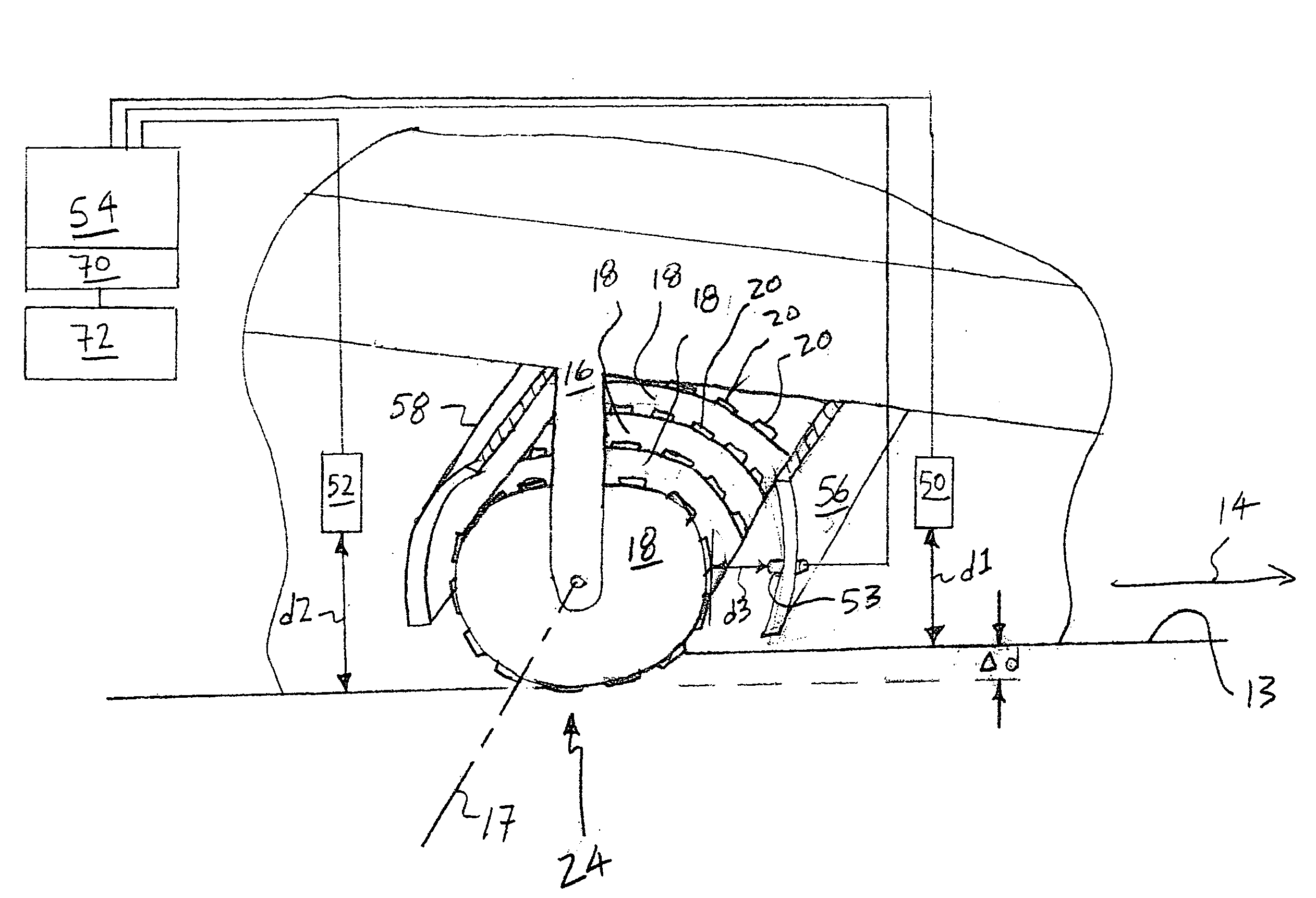

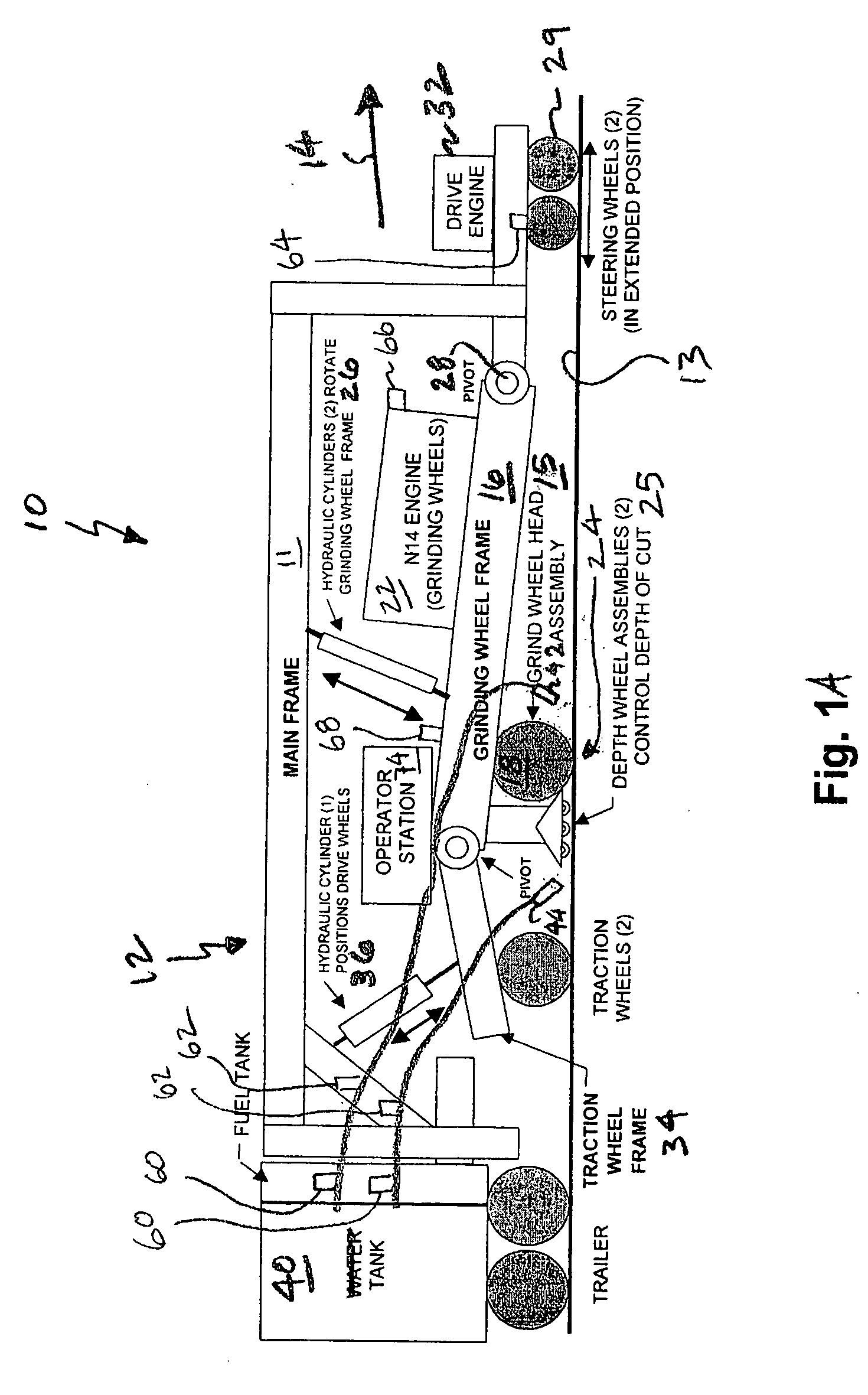

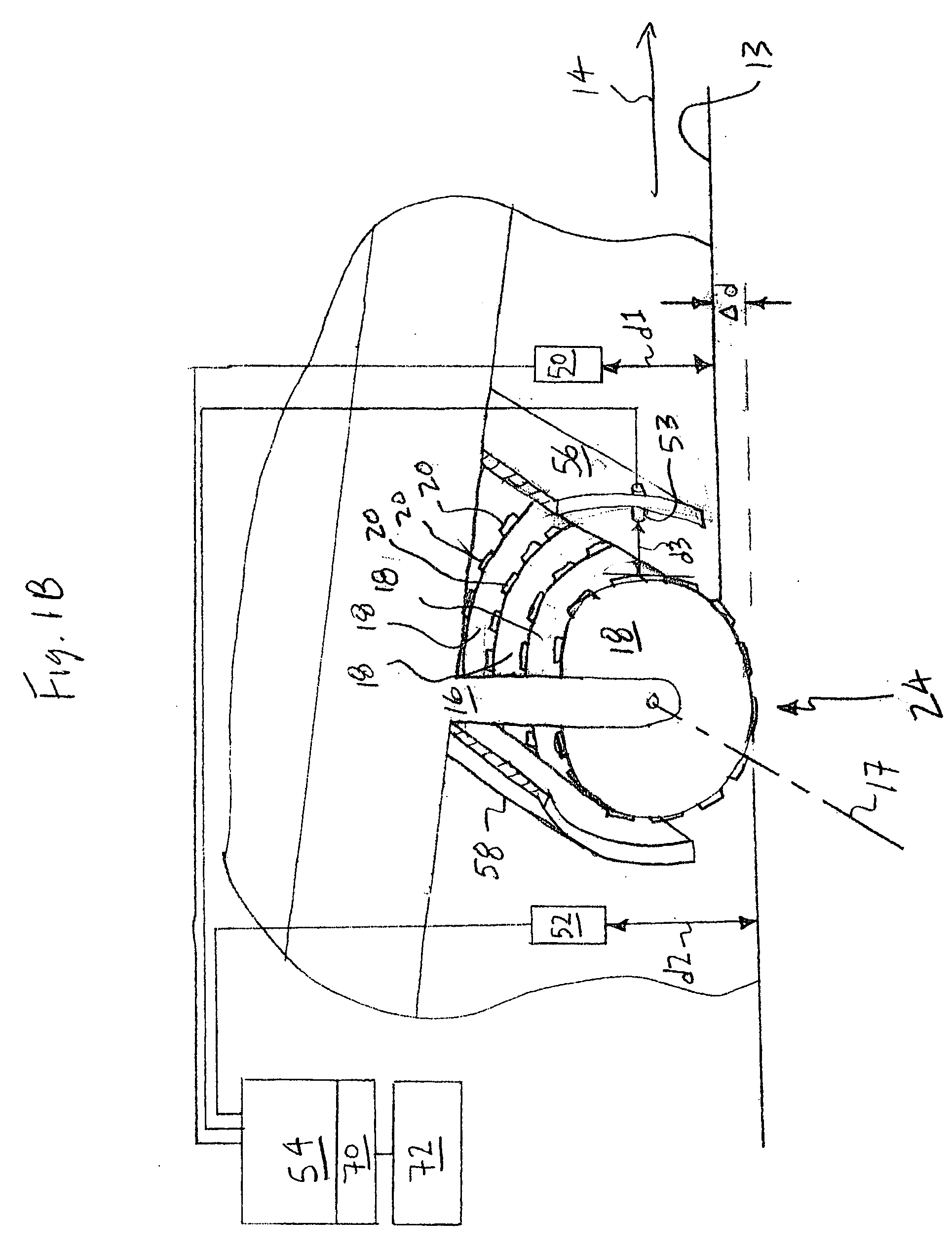

[0048]A system 10 was fabricated substantially as shown and described hereinabove. The roadway grinding machine was a Boart-Longyear PC5000B. Processor 54, memory 70 and user interface 72 were provided by a Wintel personal computer (i.e., a notebook computer having an Intel® (Intel Corporation) processor running a Windows™ (Microsoft Corporation) operating system). The following sensors were used.

Depth of Cut sensors 50, 52:

[0049]Migatron RPS-401 ultrasonic displacement transducers (4)

Grinding Head Diameter sensors 53:

[0050]Migatron RPS-401 ultrasonic displacement transducers (2)

Steering Wheel Motion (speed sensors 64):

[0051]Efector IGC206 inductive proximity sensor (2)

Engine RPM sensor 66 (grinding wheel head rpm sensor):

[0052]Efector IGC206 inductive proximity sensor

[0053]Kistler 5127B13 coupler and 8774A50 accelerometer

Cooling Water Pressure sensor 60:

[0054]Omega PX303-050G10V

Cooling Water Temperature sensor 62:

[0055]Omega fine-wire thermocouple (inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com