Substrate processing apparatus and substrate processing method

a substrate processing and processing apparatus technology, applied in the direction of cleaning processes and apparatus, chemistry apparatus and processes, cleaning using liquids, etc., can solve the problems of reducing and achieve the effect of improving the throughput of the substrate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) First Embodiment

[0080](1-1) Configuration of Substrate Processing Apparatus

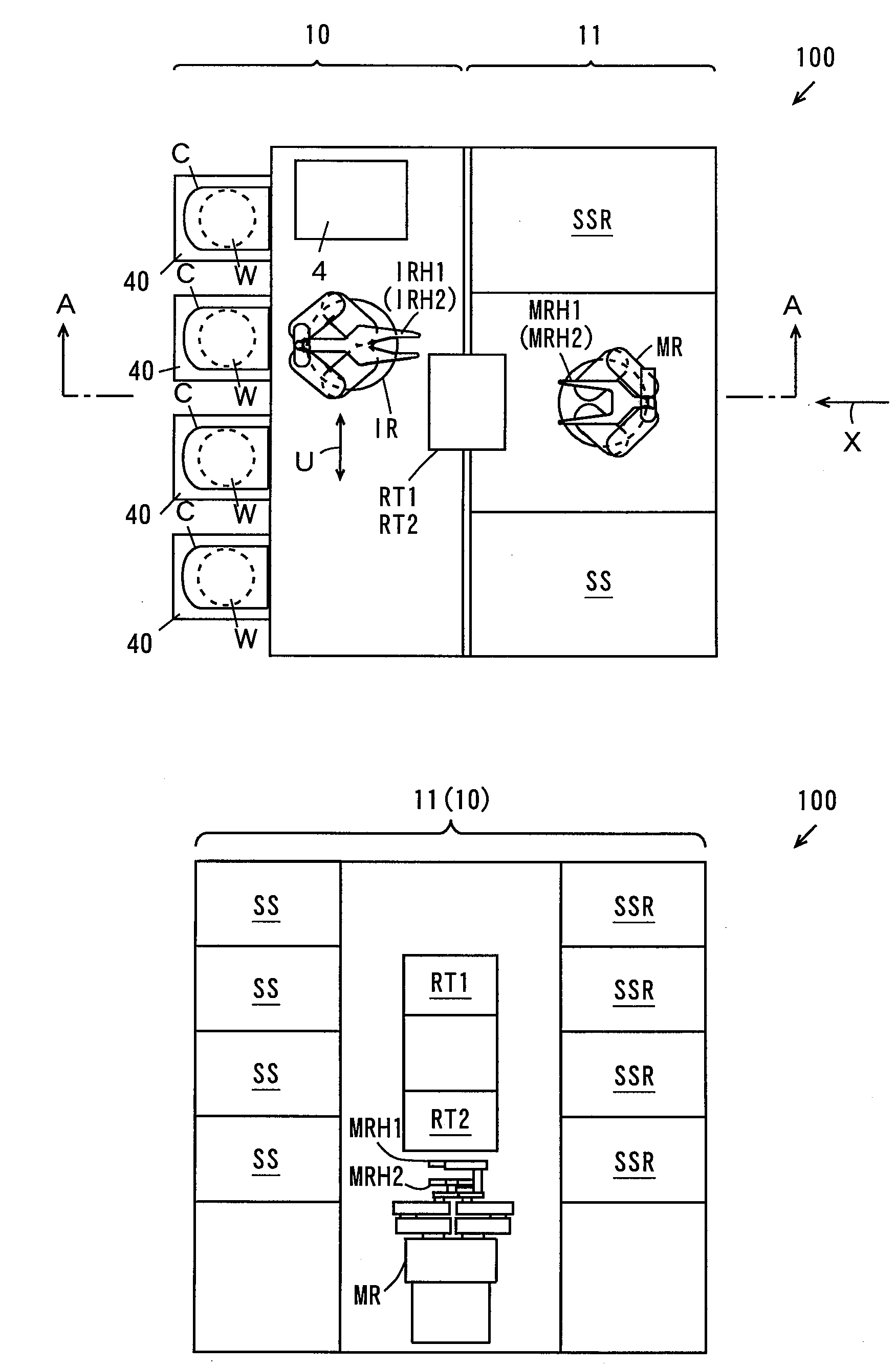

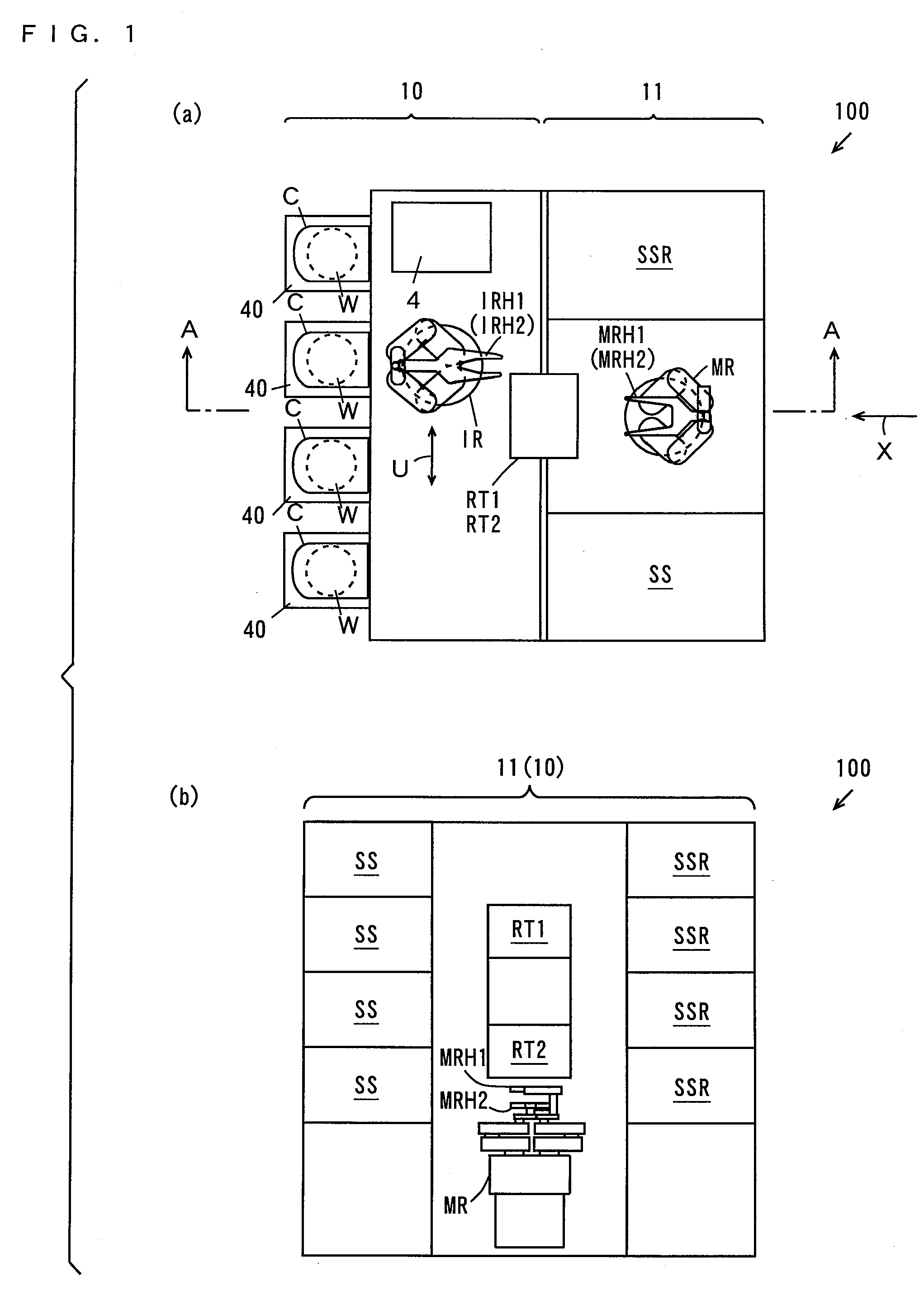

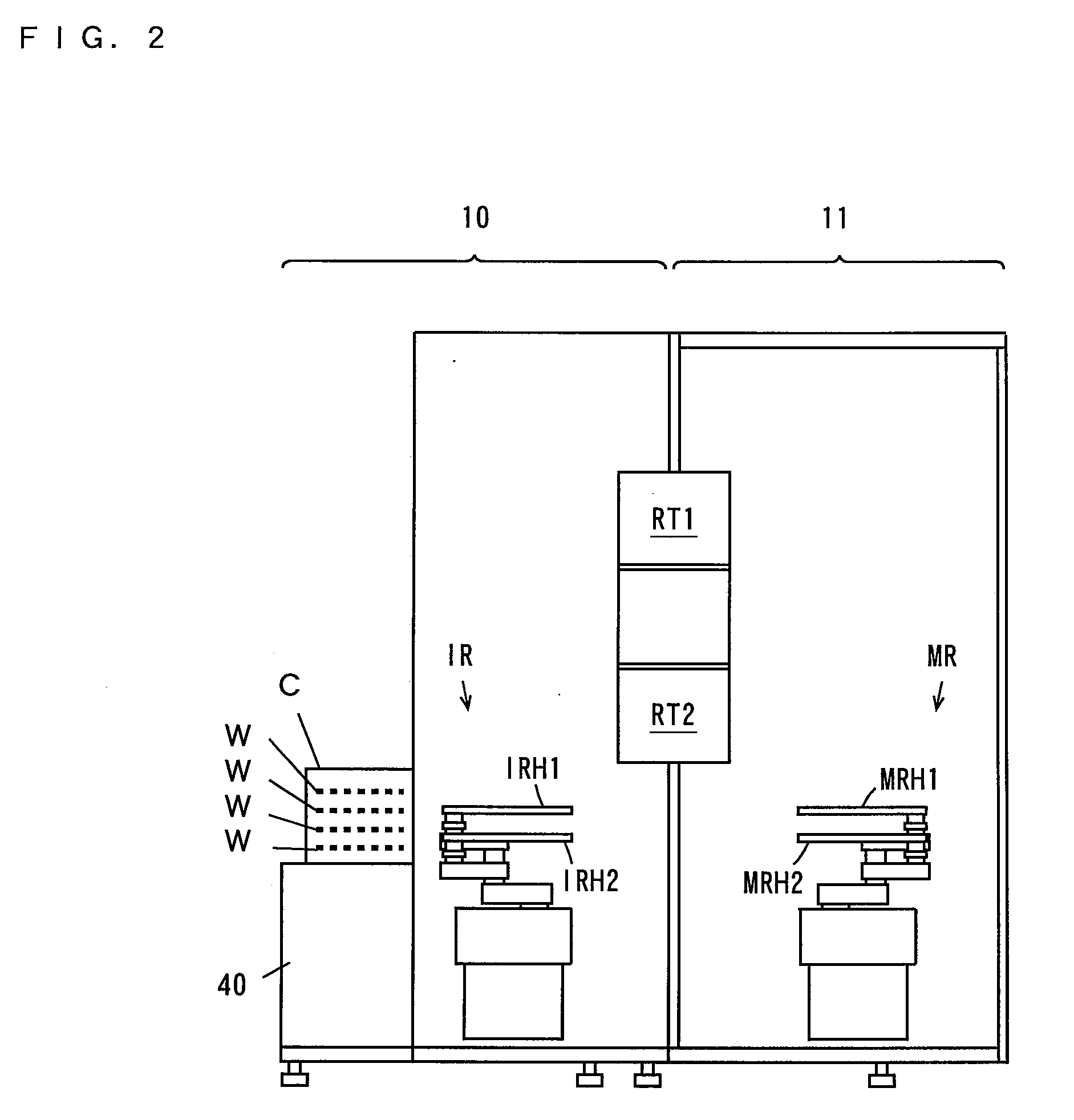

[0081]FIG. 1 is a schematic view showing a configuration of a substrate processing apparatus according to a first embodiment. FIG. 1(a) is a plan view of the substrate processing apparatus and FIG. 1(b) is a side view in which the substrate processing apparatus of FIG. 1(a) is seen from the direction of the arrow X. FIG. 2 is a schematic view showing a cross section of FIG. 1(a) taken along the line A-A.

[0082]As shown in FIG. 1(a), the substrate processing apparatus 100 includes an indexer block 10 and a processing block 11. The indexer block 10 and the processing block 11 are provided in parallel to each other.

[0083]The indexer block 10 is provided with a plurality of carrier platforms 40, an indexer robot IR and a controller 4. Carriers C that store a plurality of substrates W in multiple stages are placed on the carrier platforms 40, respectively.

[0084]The indexer robot IR is constructed so that it can...

second embodiment

(2) Second Embodiment

[0184](2-1) Configuration of Substrate Processing Apparatus

[0185]FIG. 11 is a schematic view showing a configuration of a substrate processing apparatus according to a second embodiment. FIG. 11(a) is a plan view of the substrate processing apparatus, and FIG. 11(b) is a side view in which the substrate processing apparatus of FIG. 11(a) is seen from the direction of the arrow X.

[0186]As shown in FIG. 11(a), the configuration of the substrate processing apparatus 100a according to the present embodiment is different from the configuration of the substrate processing apparatus 100 according to the first embodiment in that the back surface cleaning units SSR are provided in the region where the top surface cleaning units SS are supposed to be provided (FIG. 1) in the processing block 11. That is, twice as many the back surface cleaning units SSR (eight units) as those of the substrate processing apparatus 100 are provided in the substrate processing apparatus 10a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com