Mascara brush with curving bristle portion

a brush and curving technology, applied in the field of brushes, can solve the problems of affecting the use of the user, unable to achieve satisfactory comb-through, and difficulty in achieving satisfactory comb-through without using a separate implement such as a small plastic comb, so as to achieve no risk of damage and/or contamination of the comb or other objects, and quick and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

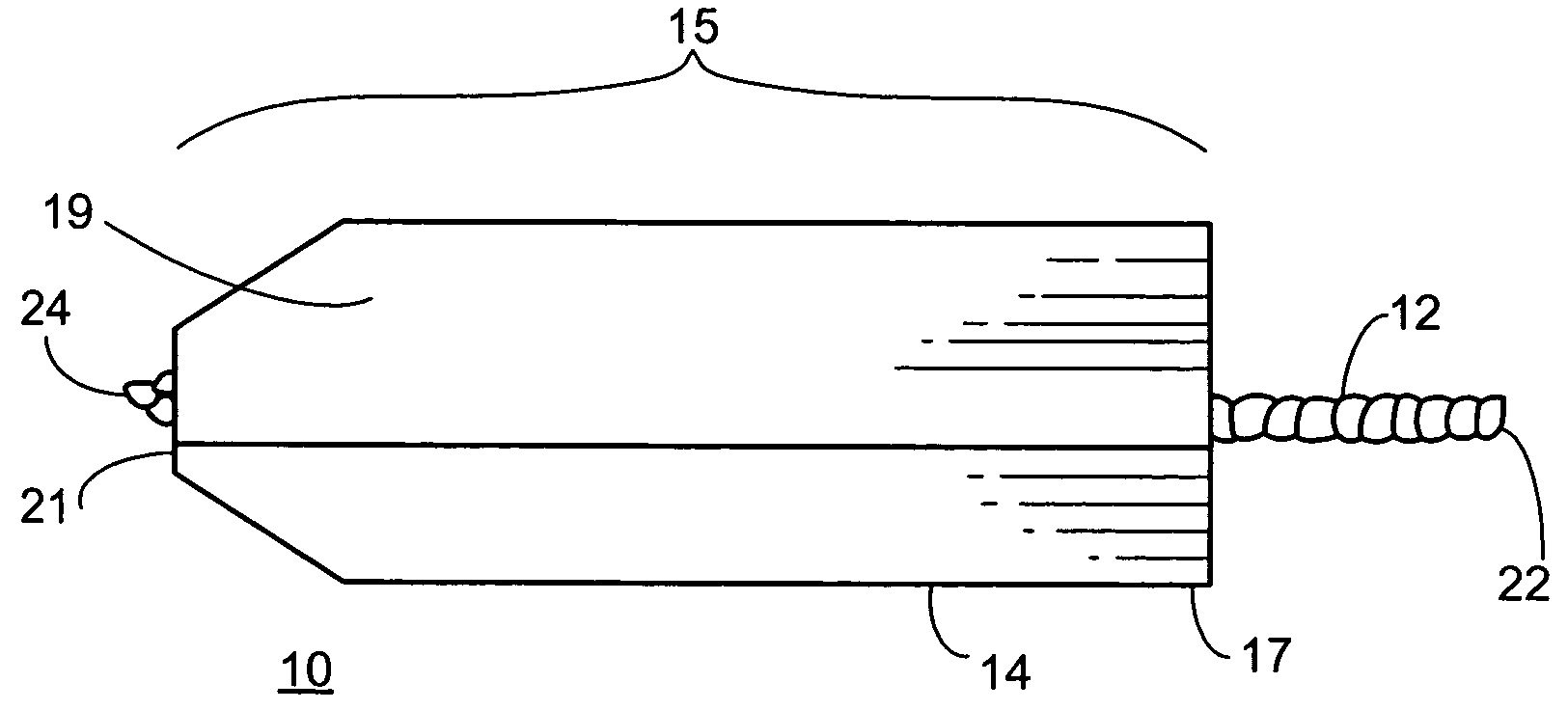

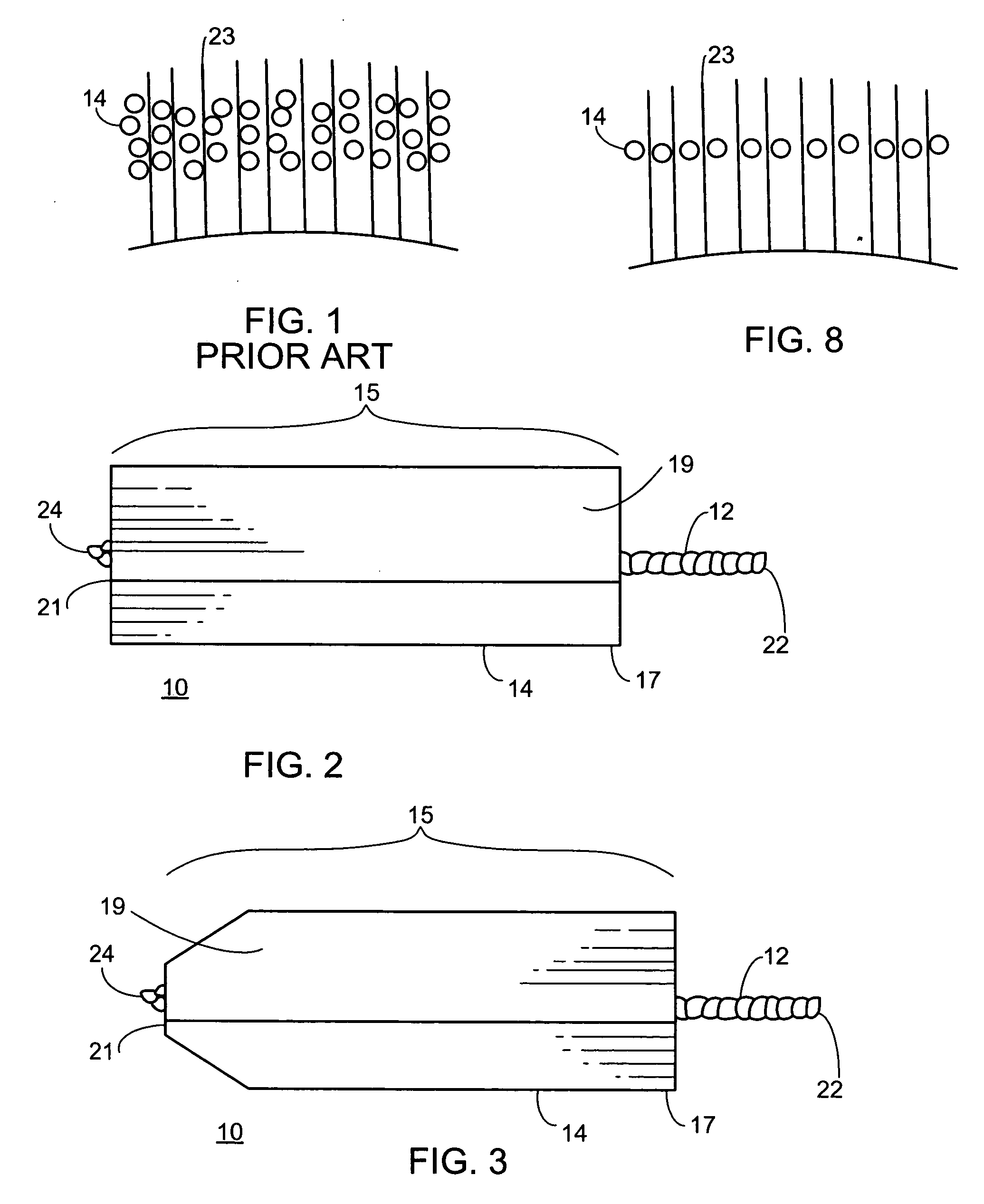

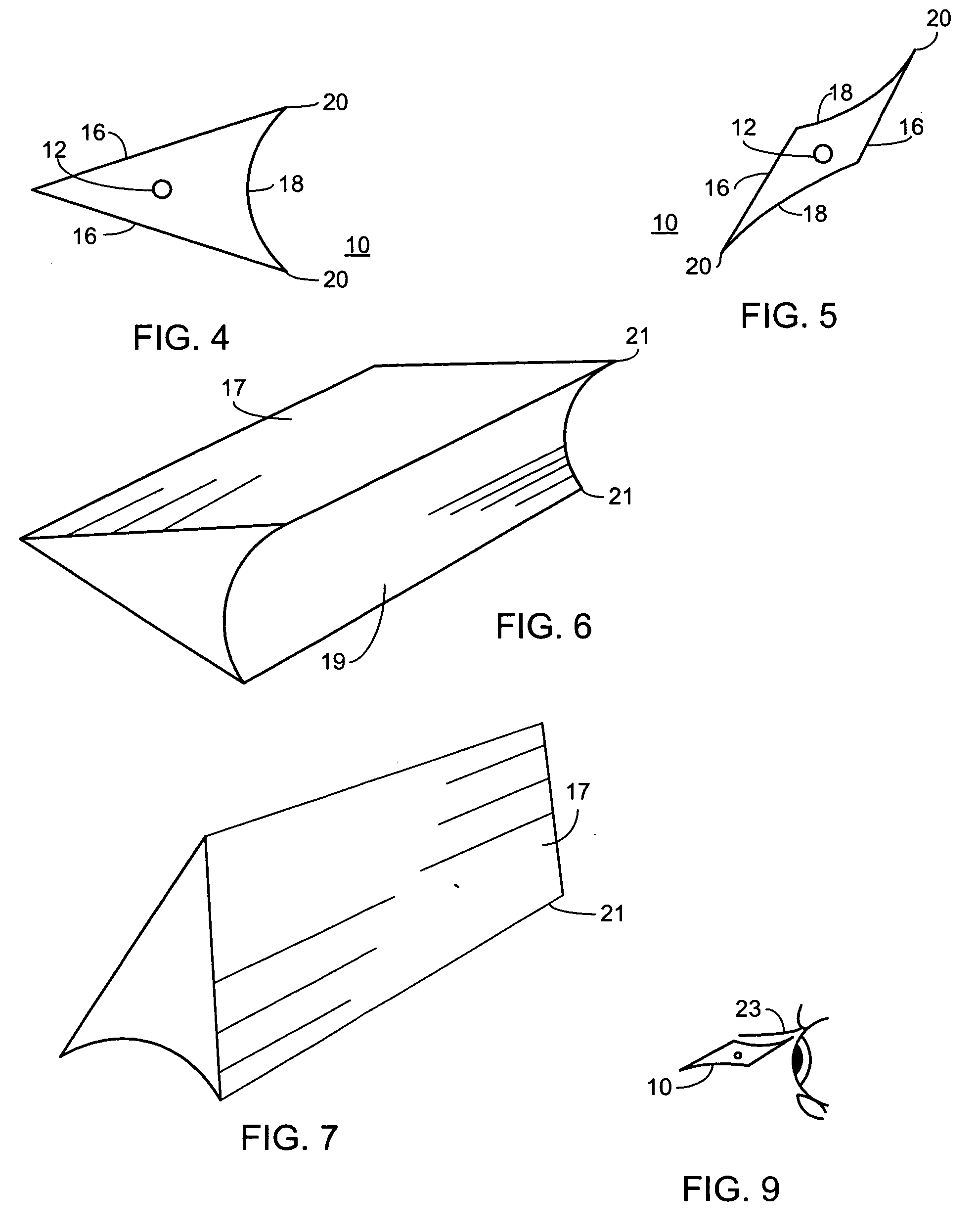

[0025]FIGS. 2, 4, 6 and 7 show an embodiment of the invention. Similar to conventional brushes, the brush 10 has an elongated, axially rectilinear core 12 constituted of two helically twisted-together runs of metal wire, and a multiplicity of fibers or bristles 14. The bristles 14 (for example nylon fibers) form an array 15, each bristle clamped between the two runs of wire and having opposed free tips extending radially outwardly therefrom. The two wire runs may be separate lengths of wire or opposed legs of a single initially U-shaped wire. The core has a proximal end 22 and a distal end 24 to which the bristle array extends, the proximal end of the bristle array being spaced distally from the proximal end of the core so as to leave an exposed proximal length of the core for mounting in the stem of a mascara container cap. The manufacture and arrangement of such structures are well known in the art, and accordingly need not be further described.

[0026]A conventional brush typically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com