Angle sensor

a technology of angle sensor and angle sensor, which is applied in the direction of galvano-magnetic hall-effect device, galvano-magnetic device, instruments, etc., can solve the problems of general availability of magnetic angle sensor commercially available today, and achieve the effect of optimizing shape and siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

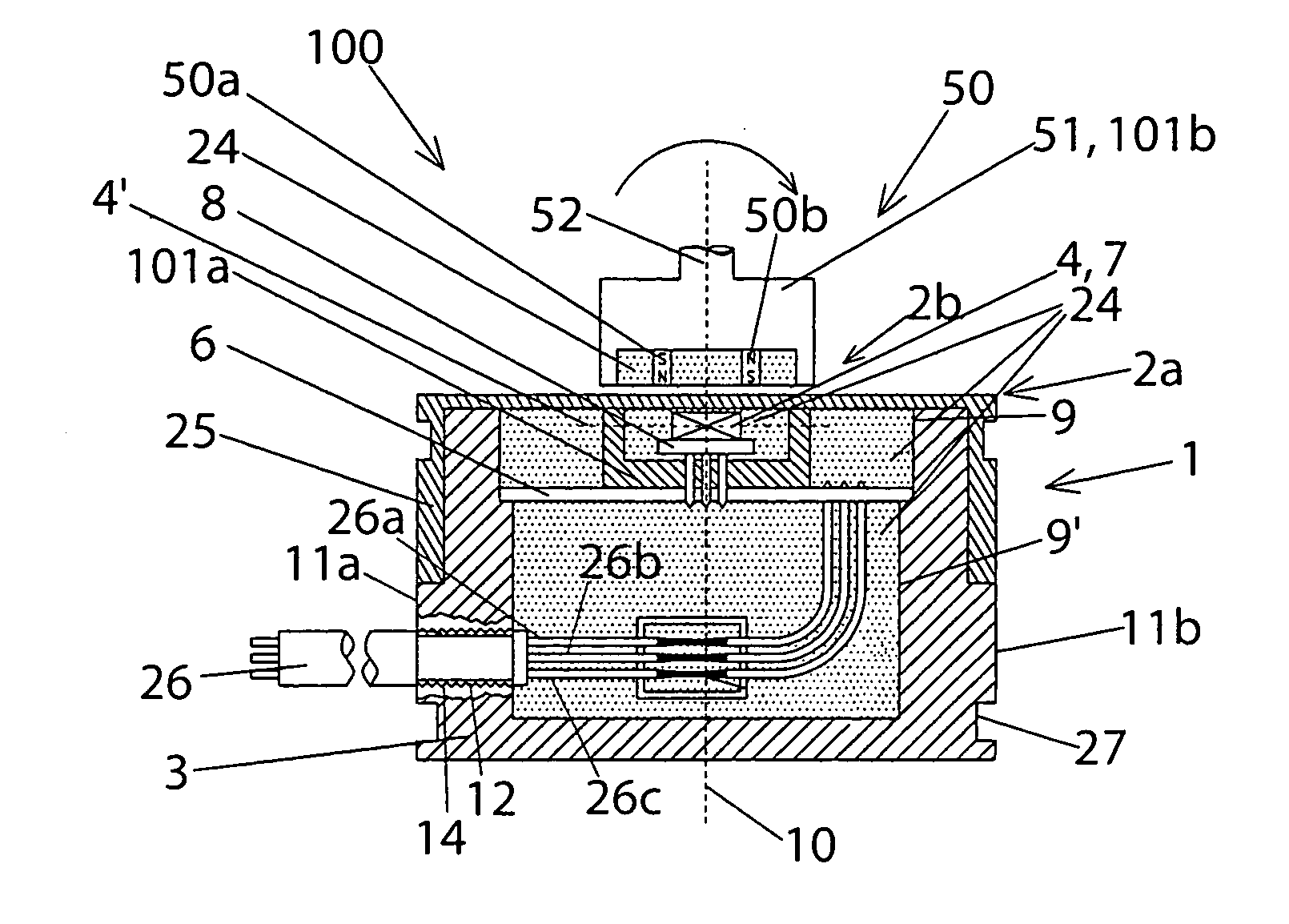

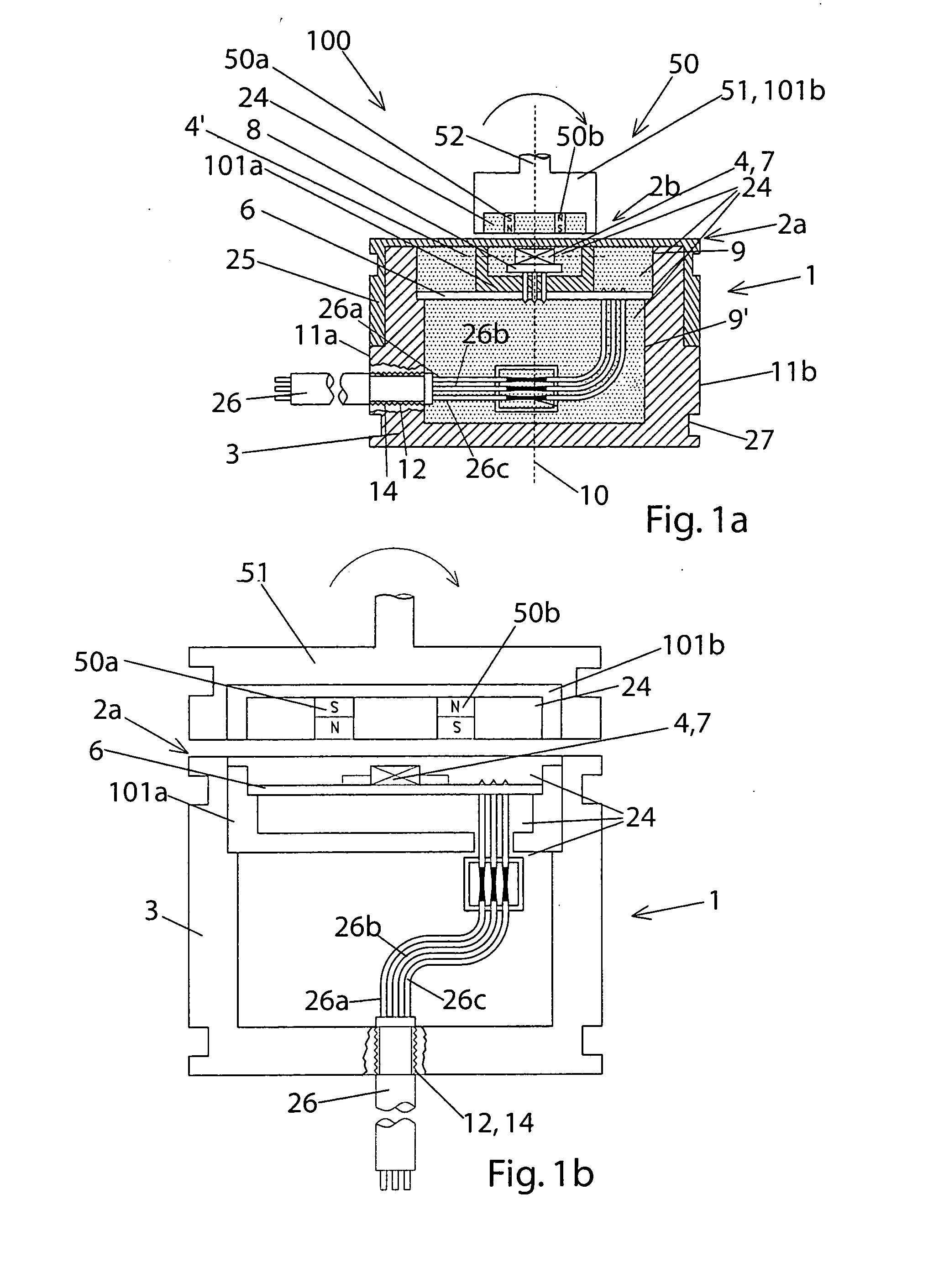

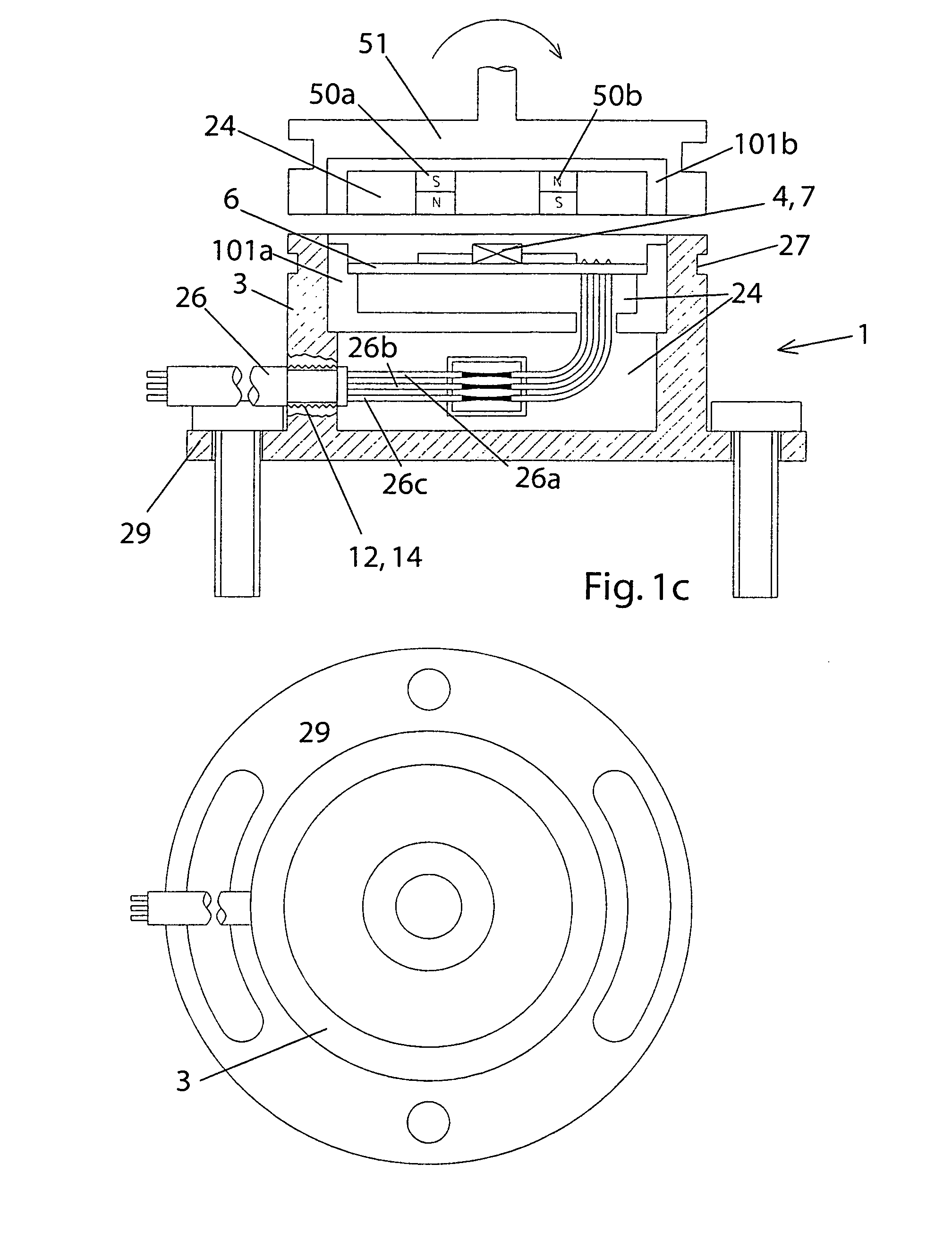

[0072]FIG. 1a shows a sensor unit 100 comprised of an angle sensor 1 and a magnet unit 50, comprising two encoder magnets 50a, b, cut along the axes 10a, b, which are preferably shared by the magnet unit 50 and the angle sensor 1, wherein the encoder is rotatable around its rotation axis 10b, relative to the typically still standing angle sensor 1.

[0073]The magnet unit 50 is thus comprised of an encoder core body 51, typically provided as a symmetrical, in particular rotation symmetrical in top view, circular, e.g. core body 51, from whose backside a not completely illustrated central pinion 52 protrudes by means of which the core body 51 can be inserted into a blind bore hole of another component, or clamped.

[0074]On or in the forward face surface of the core body 51, the actual encoder is mounted, comprised in this case of a pot shaped, encoder shielding 101b, which is also symmetric in top view, in particular rotation symmetric, e.g. circular, which points away with its open side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com