Wall fabrication system and method

a wall and fabrication system technology, applied in the field of building construction, can solve the problems of difficulty in properly filling the cavity, difficulty in ensuring the safety of the user, and widespread application of automatic manufacturing to the manufacture of traditional site-built homes, etc., and achieves the effects of improving insulation, reducing the risk of mold growth, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

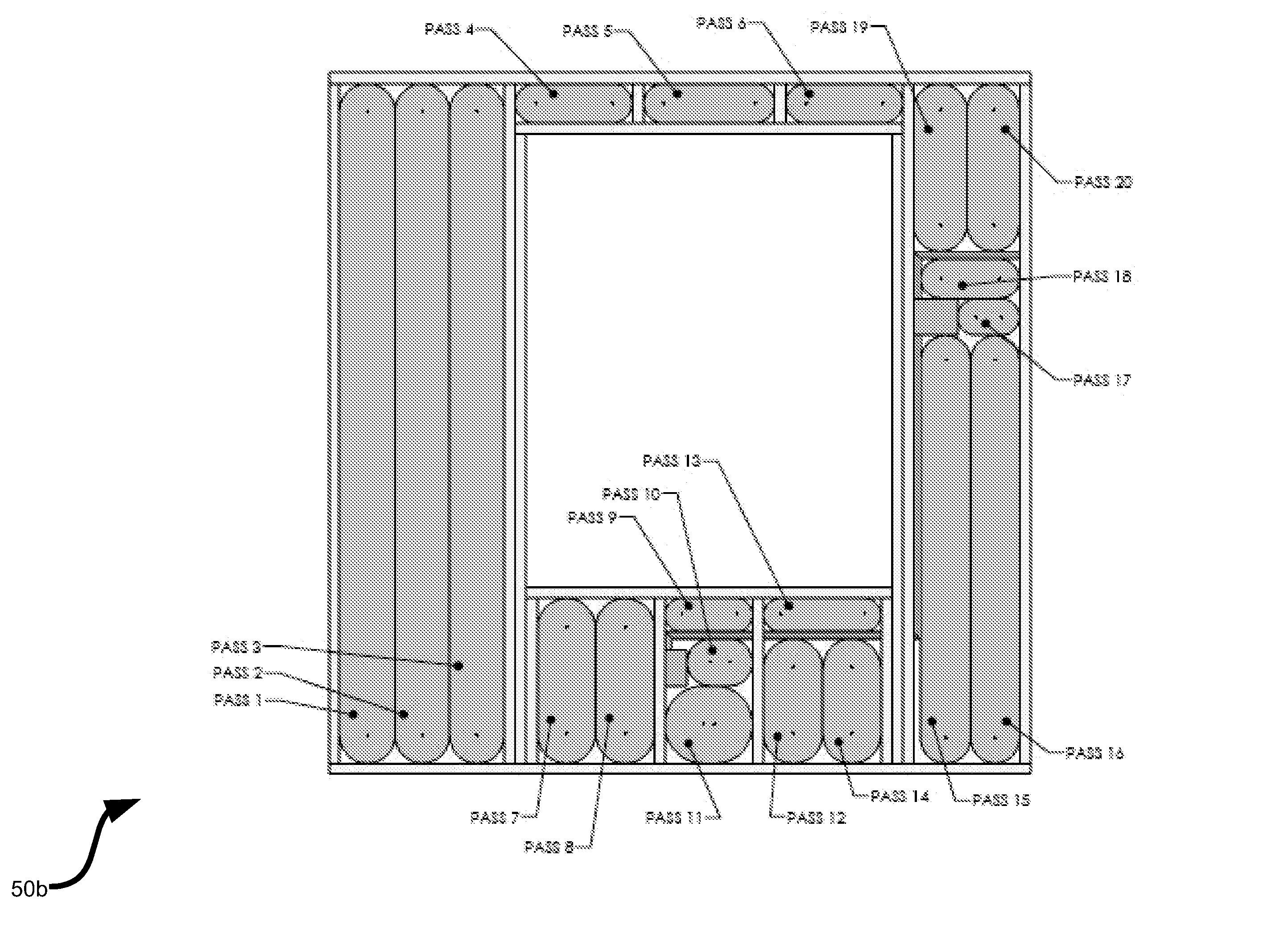

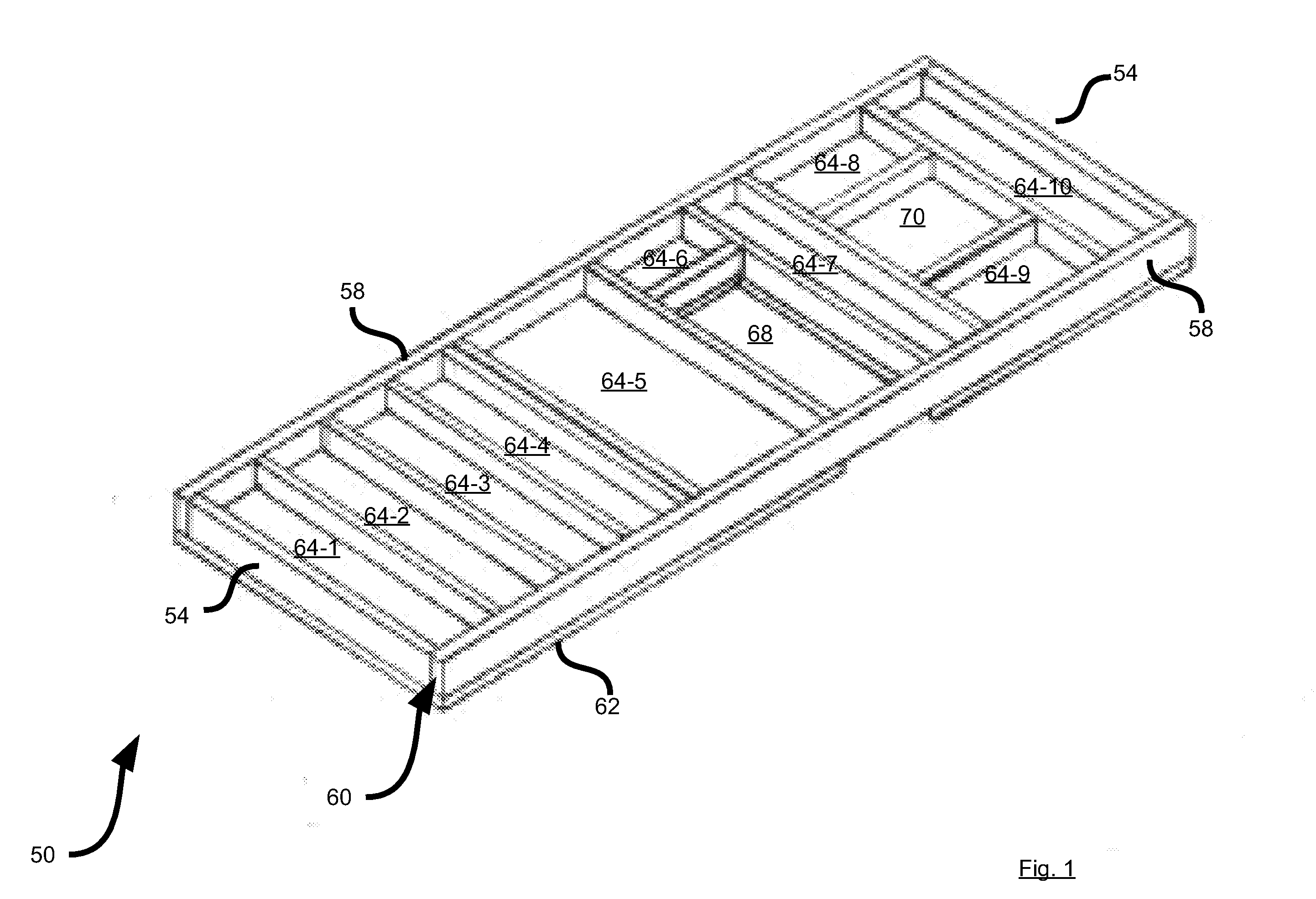

[0040]Referring now to FIG. 1, a wall section for a traditional site-built home is indicated generally at 50. Wall section 50 comprises a plurality of substantially parallel vertical studs 54 transversely affixed to a plurality of substantially parallel horizontal studs 58. Not all vertical studs 54 and horizontal studs 58 are labeled in FIG. 1. Studs 54, 58 define a frame 60 that is covered on one side by drywall 62 or other type of covering such as plywood, wood or the like. Studs 54, 58 act as supports for wall section 50.

[0041]It should be understood that terms such as “horizontal” and “vertical” are used for convenience to assist in understanding the discussion herein, but do not imply herein that studs of a frame need to be arranged in such a manner.

[0042]Studs 54, 58 can be wood and / or metal and / or any other suitable type of home framing material for a traditional site-built home. Studs 54, 58 are affixed to each other using nails, staples and / or any other type of suitable fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com