Substrate processing apparatus, method of manufacturing semiconductor device, and reaction vessel

a processing apparatus and semiconductor technology, applied in the direction of coatings, metallic material coating processes, chemical vapor deposition coatings, etc., can solve the problems of affecting the uniformity of wafer in-plane film thickness, the necessity for a plurality of gas nozzles of different lengths, and the inability to achieve uniform thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

Modifications

[0109]The following range of modifications can be made to the first embodiment of the present invention described above. >

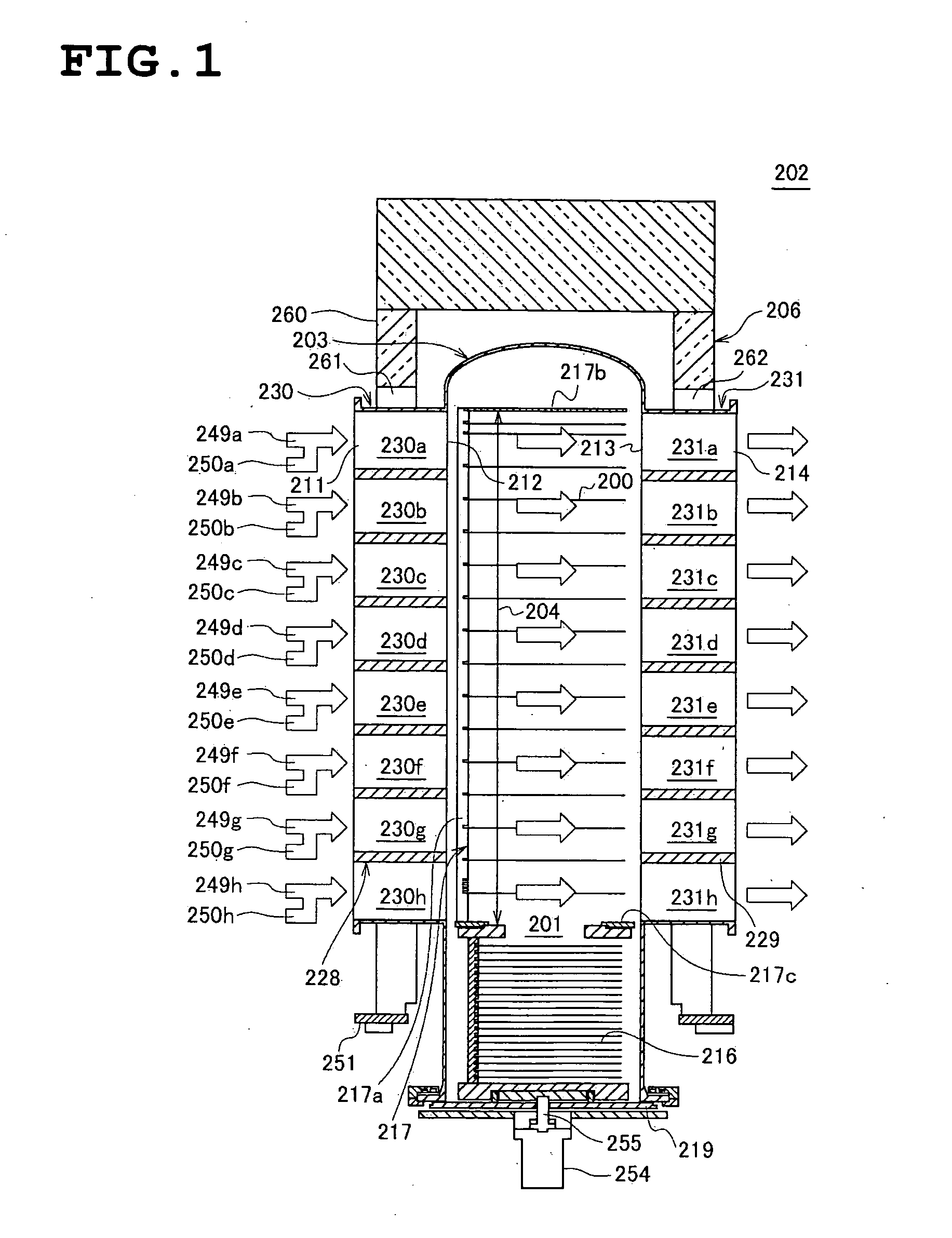

[0110]While the first embodiment described above describes, as shown in FIG. 3, a case in which a plurality of gas introduction partition portions 230a to 230h and gas exhaust partition portions 231a to 231h are integrally provided in a single gas inlet tube 230 and a single gas exhaust tube 231a as a result of these long, elliptically-shaped pipes being partitioned in the vertical direction by partition walls 228, 229, the present invention is not limited thereto.

[0111]For example, as in a first modification thereof shown in FIG. 4, on the basis of a plurality of gas inlet tubes 230 and gas exhaust tubes 231 of a cylindrical shape being arranged in rows in the vertical direction of the reaction tube 203 and joined by way of common flanges 232, 233, the plurality of gas introduction partition portions 230a to 230h and gas exhaust partition portions 2...

second embodiment

Modifications

[0164]The following range of modifications can be made to the second embodiment of the present invention described above.

>

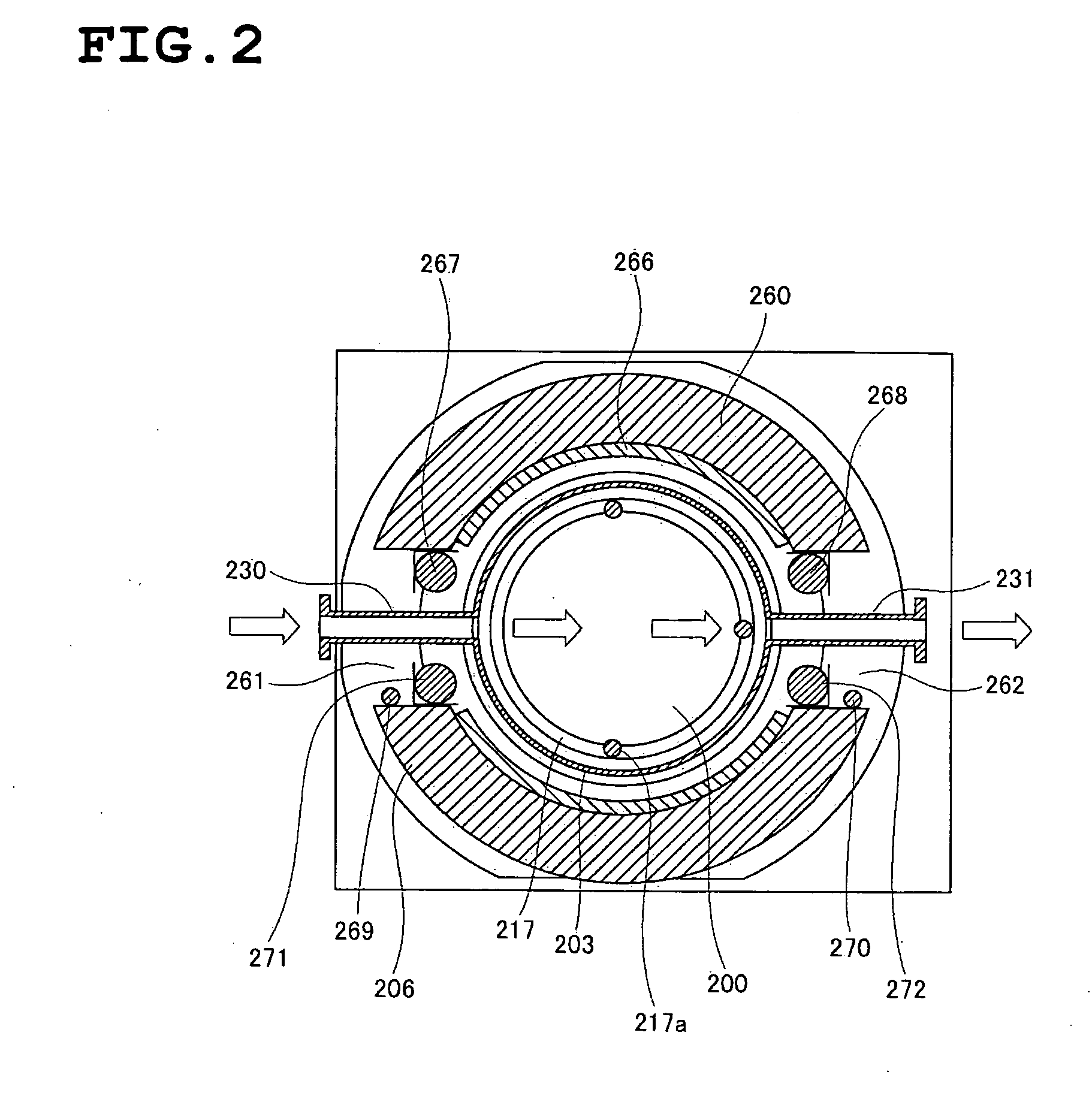

[0165]While the embodiment described above describes an example in which the processing partition walls provided in the port describe a disc shape and are formed in a certain arrangement and number in the port, the shape, arrangement and number of these processing partition walls is not limited thereto.

>

[0166]In addition, while the port 21 of the embodiment described above is integrated, an assembled body that is disassemblable into processing partition units may be adopted. For example, a port 217 formed as a laminate of port constituent elements may be adopted. The assembly of this port is based on a plurality of port constituent elements being disposed in an arrangement in which one port constituent element is placed on another port constituent element in sequence.

[0167]For example, as in a first modification shown in FIG. 26, the basic configurat...

example processing conditions

[0278]As an example of the processing conditions for processing wafers in the processing furnace of the embodiments for the film formation of a Si3N4 film includes a processing pressure of 30 Pa, the employment of dichlorosilane gas (SiH2Cl2) and ammonia gas (NH3) as the gas types, and a gas supply flow rate to the partition portions of SiH2Cl2 0.1 sccm and NH3 0.5 sccm may be employed. The conditions additionally include a processing temperature in the reaction tube 203 heated by the heater wire 266a of 760° C., a temperature in the gas inlet tube 230 heated by the gas inlet tube side wall heating body 267a of 300° C., and a temperature of the gas exhaust tube 231 heated by the gas exhaust tube side wall heating body 268a of 300° C.

[0279]The wafer processing is administered p with each of these respective processing conditions maintained to a constant value within a respective range thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com