Model railroad track switch actuator assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

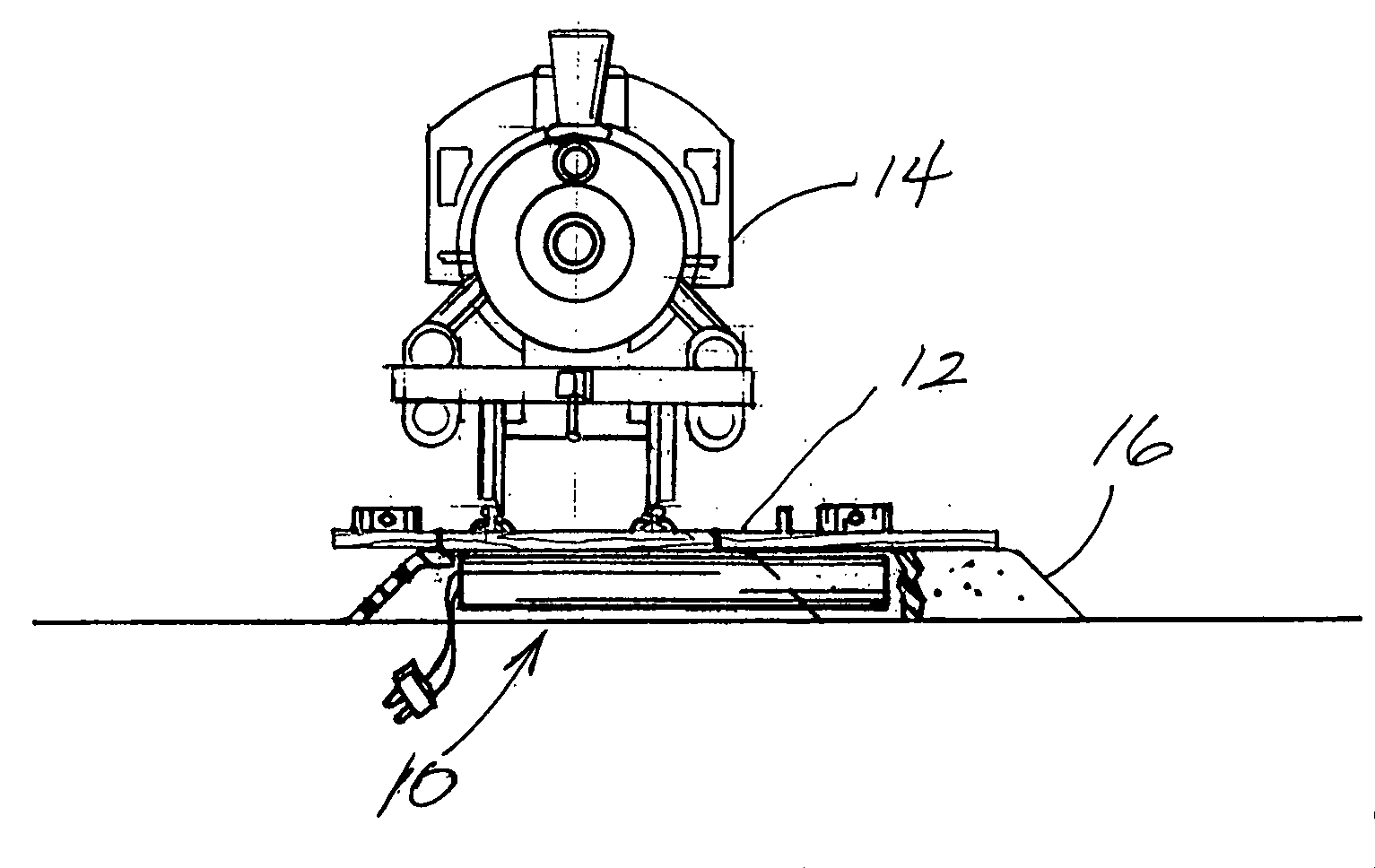

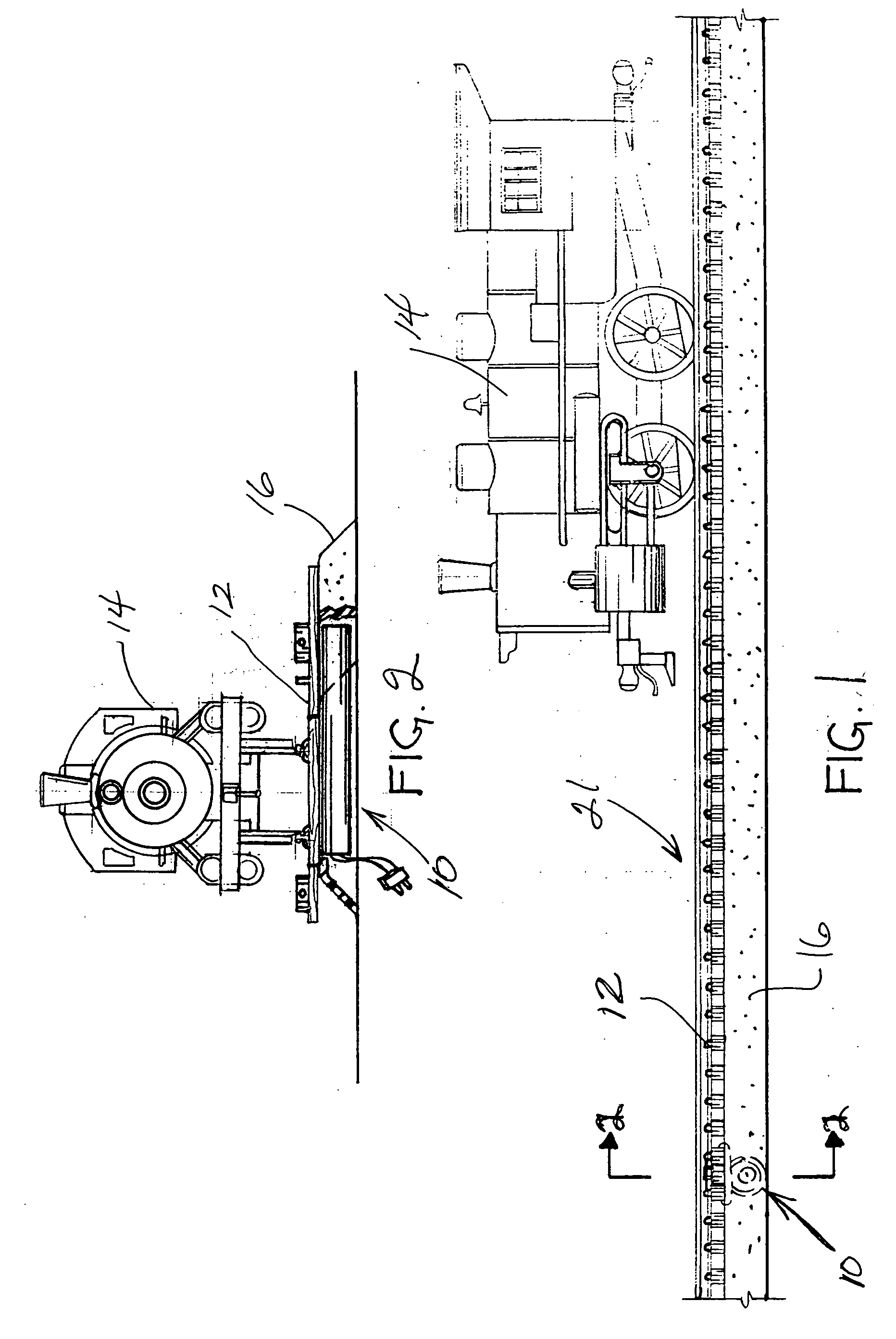

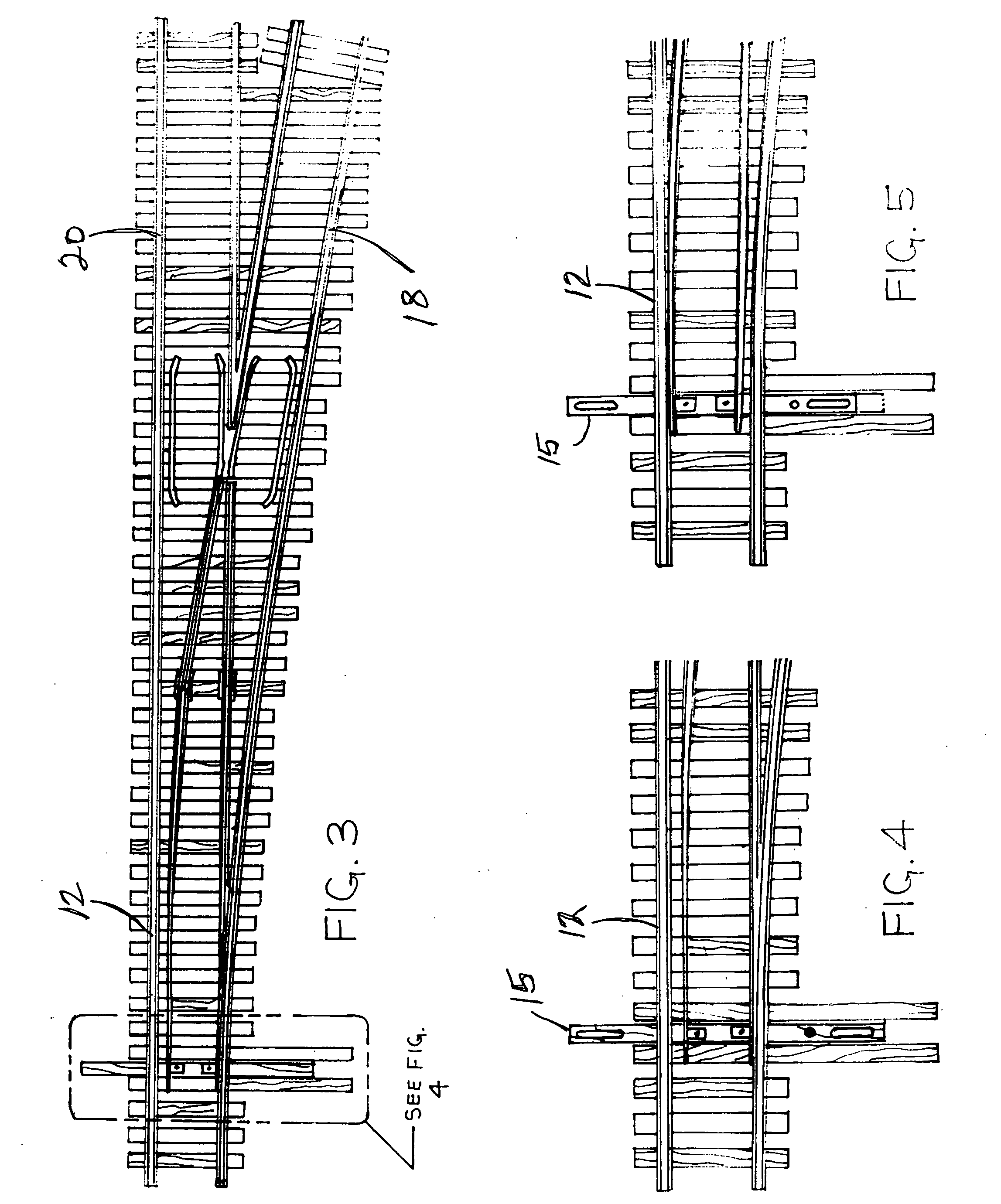

[0026]Referring to the accompanying figures, it will be seen that a track switch actuator assembly 10 is mounted directly to the bottom of a track switch 12 in a model train layout 21 on which there is at least one model train 14. The actuator assembly 10 is preferably hidden in or partially obscured by a simulated track bed 16 as shown best in FIGS. 1 and 2. As seen best in FIGS. 3 to 7, the actuator assembly 10 is secured to the track switch 12 which is, in turn, connected to a turn out track piece 18 and a straight track piece 20. Of course, it will be understood that this turn out track configuration is shown by way of example only and that the present invention may be implemented in various other track switching configurations well known in the art of model railroads. For example, the invention may be used with curved turnouts, wye turnouts, three-way turnouts, double crossovers and the like. It will also be understood that motors used in track switch actuators will either have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com