Structural material with piezoelectric material particles

a technology of piezoelectric materials and structural materials, applied in the field of structural materials, can solve the problems of inability to properly perform ultrasonic scans, inability to accurately detect the structure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

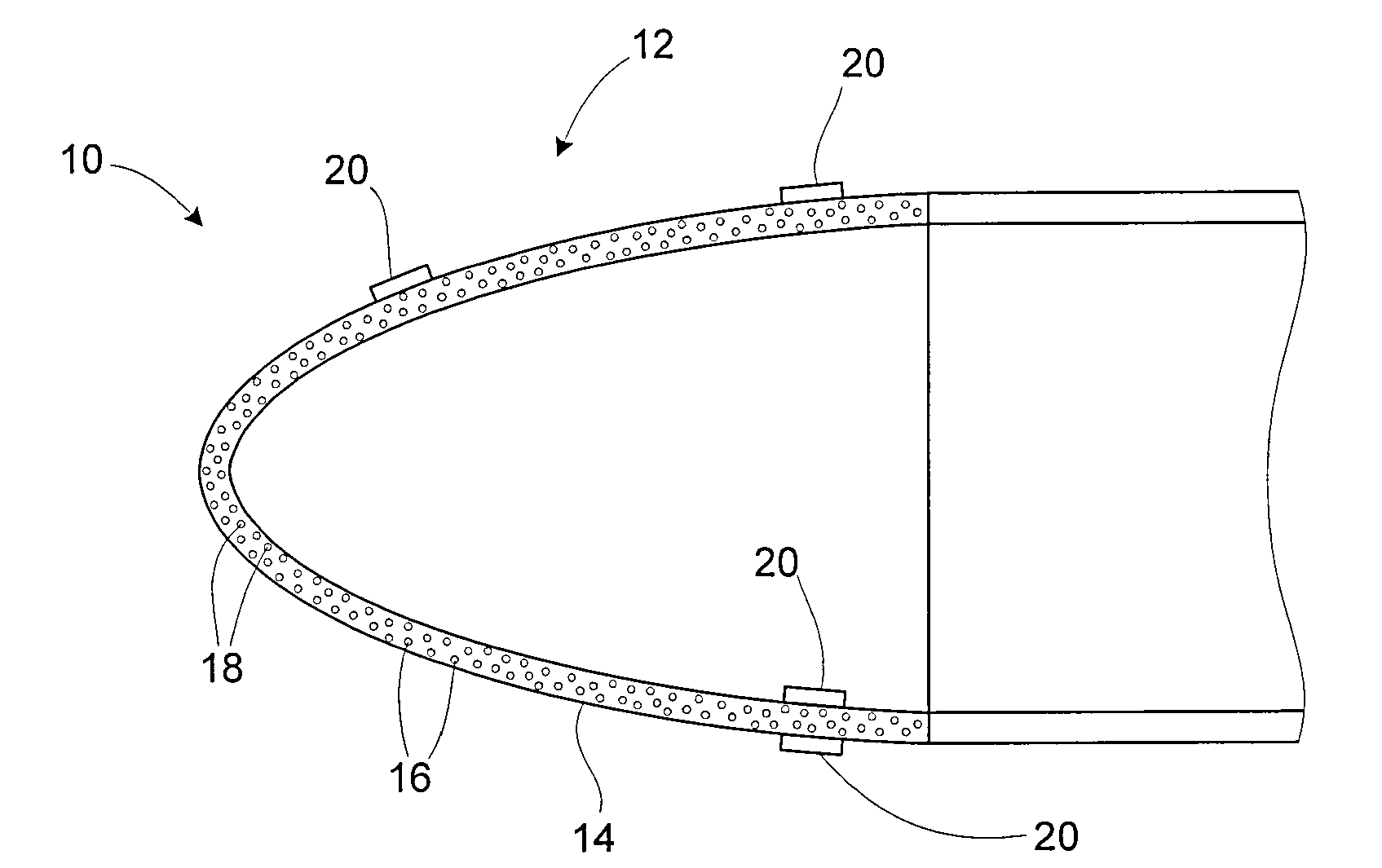

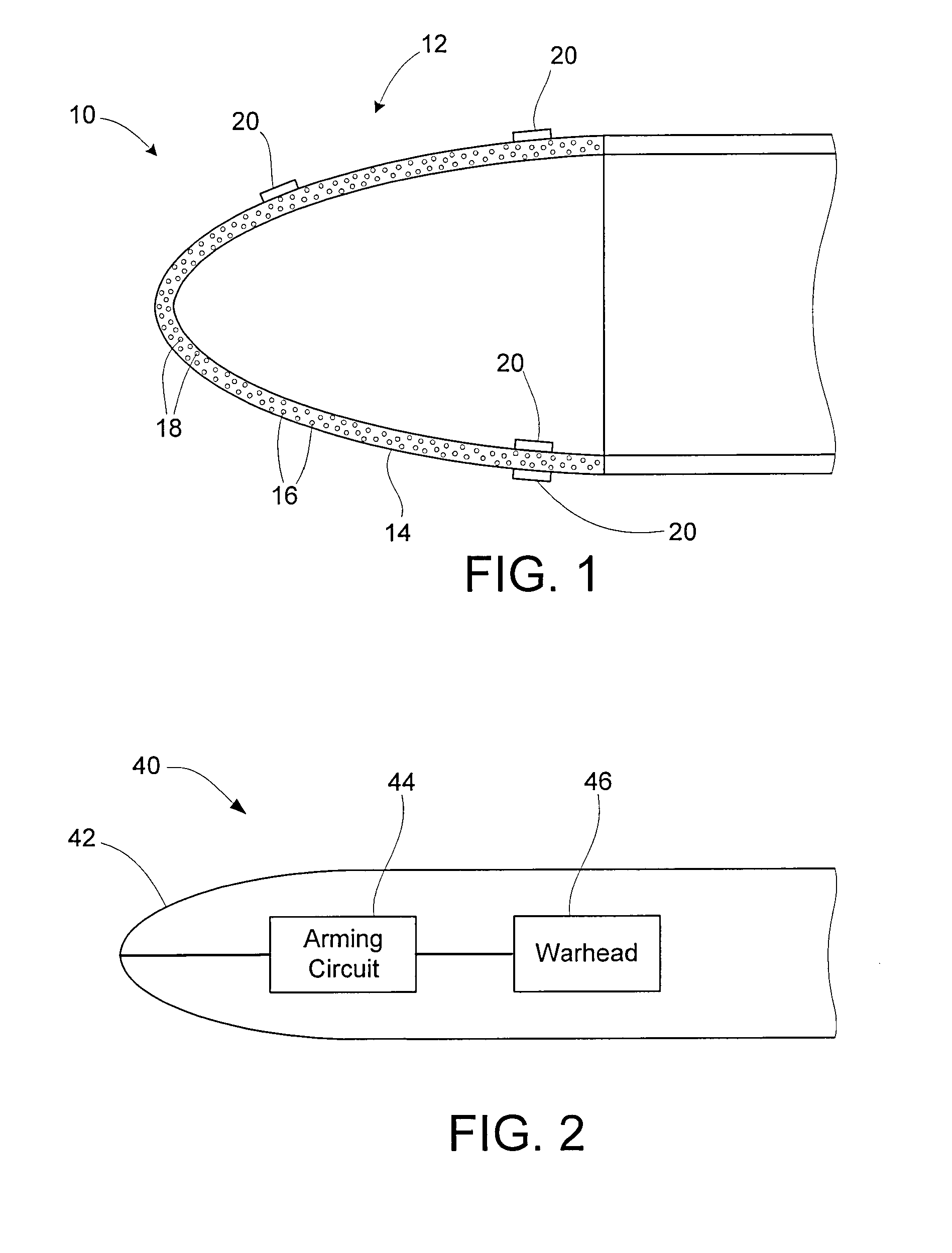

[0017]A load-bearing structural member has a continuous structural material with piezoelectric material particles mixed in throughout. The structural material may be any of a variety of suitable materials, such as polymer materials, composite materials, ceramic materials, or concrete. The piezoelectric material particles may be used for evaluating the soundness of the structural member, such as in quality control, nondestructive testing, or structural health monitoring processes. The structural member may include one or more conductive pickups used for receiving signals from the structural member. The signals may be induced by introducing ultrasonic signals or vibrational resonance signals into the structural member. The response from such induced signals may be used for quality control purposes or structural health monitoring. The piezoelectric material particles may function to provide response signals from throughout the structural material, enabling easier evaluation of the soun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight fractions | aaaaa | aaaaa |

| weight fractions | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com