Packaging System and Method for Flatware and the Like

a flatware and packaging system technology, applied in the field of flatware packaging system and method for consumers, can solve the problems of reducing the likelihood of damage to the outside box and reducing the environmental footprin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

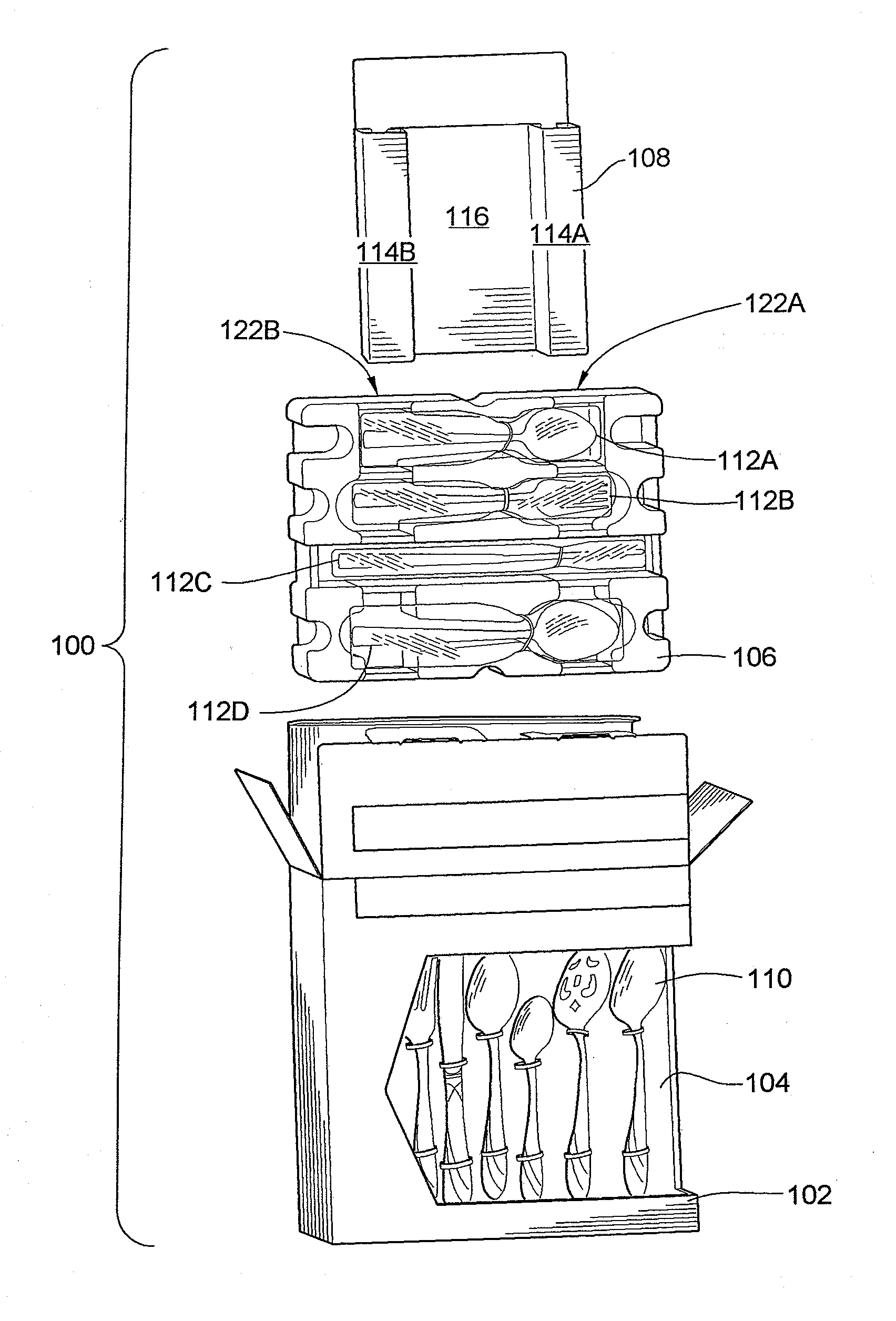

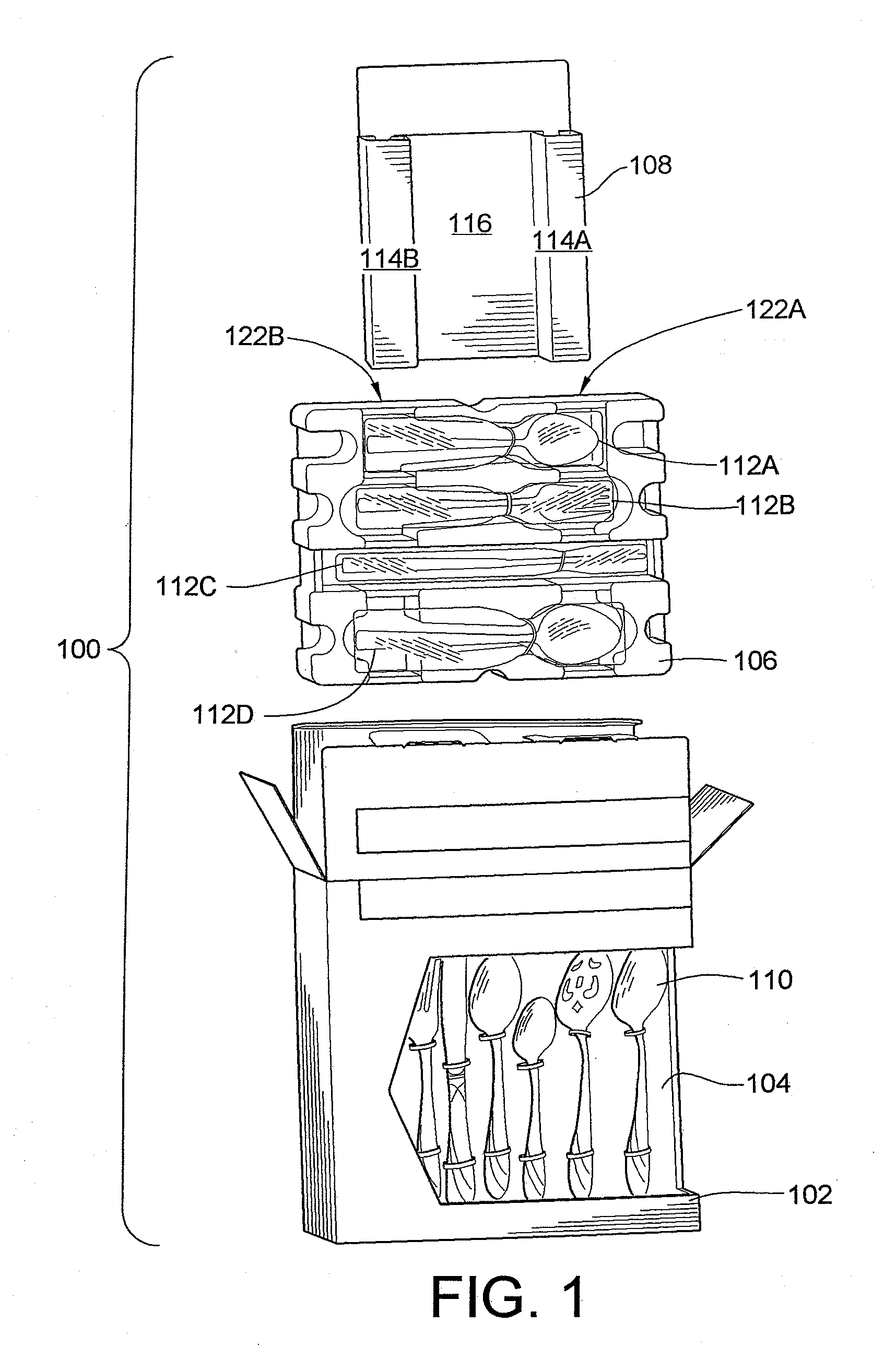

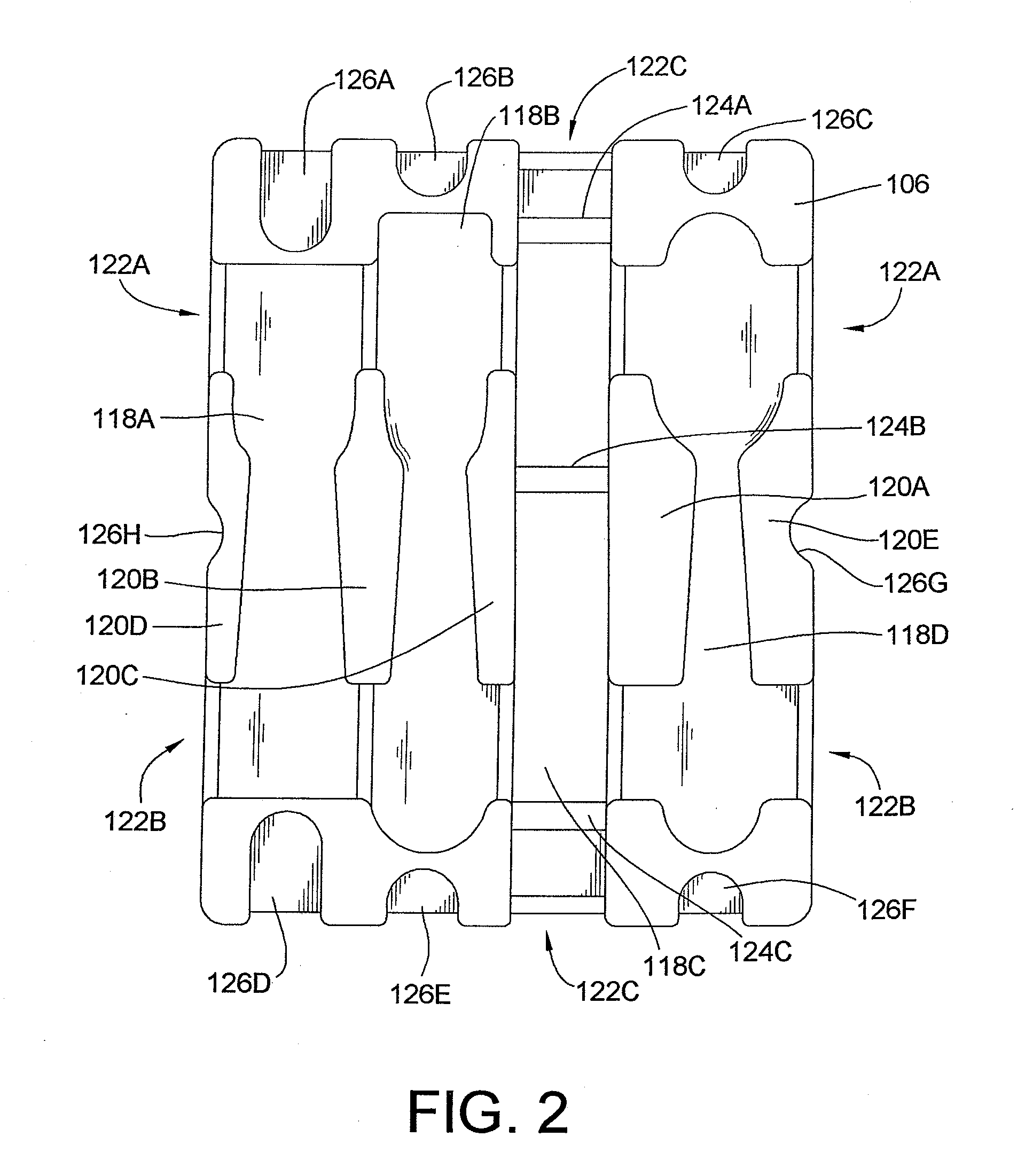

[0030]Turning now to the drawings, there is illustrated in FIG. 1 an embodiment of a packaging system 100 constructed in accordance with the teachings of the present invention. While the packaging system 100 illustrated in FIG. 1 is designed for sets of flatware, those skilled in the art will recognize from the foregoing and following discussion that embodiments of the present invention may be particularly configured to package other consumer product sets. Therefore, while the following description will describe an embodiment to the present invention particularly suited to flatware packaging, such description is provided for illustration only and should not be taken as being limiting on the scope of the present invention.

[0031]In the embodiment illustrated in FIG. 1, the packaging system 100 includes a box 102 that houses a window display board 104, and insert tray 106, and, in a preferred embodiment, a retainer 108. The window display board 104 includes a display set 110 of the ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com