Meal Component System

a meal and component technology, applied in the field of meal component systems, can solve the problems of inefficiency of the portioning out individual servings process, waste of meal components, and inability to modify meals, and achieve the effect of convenient flexible meal preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

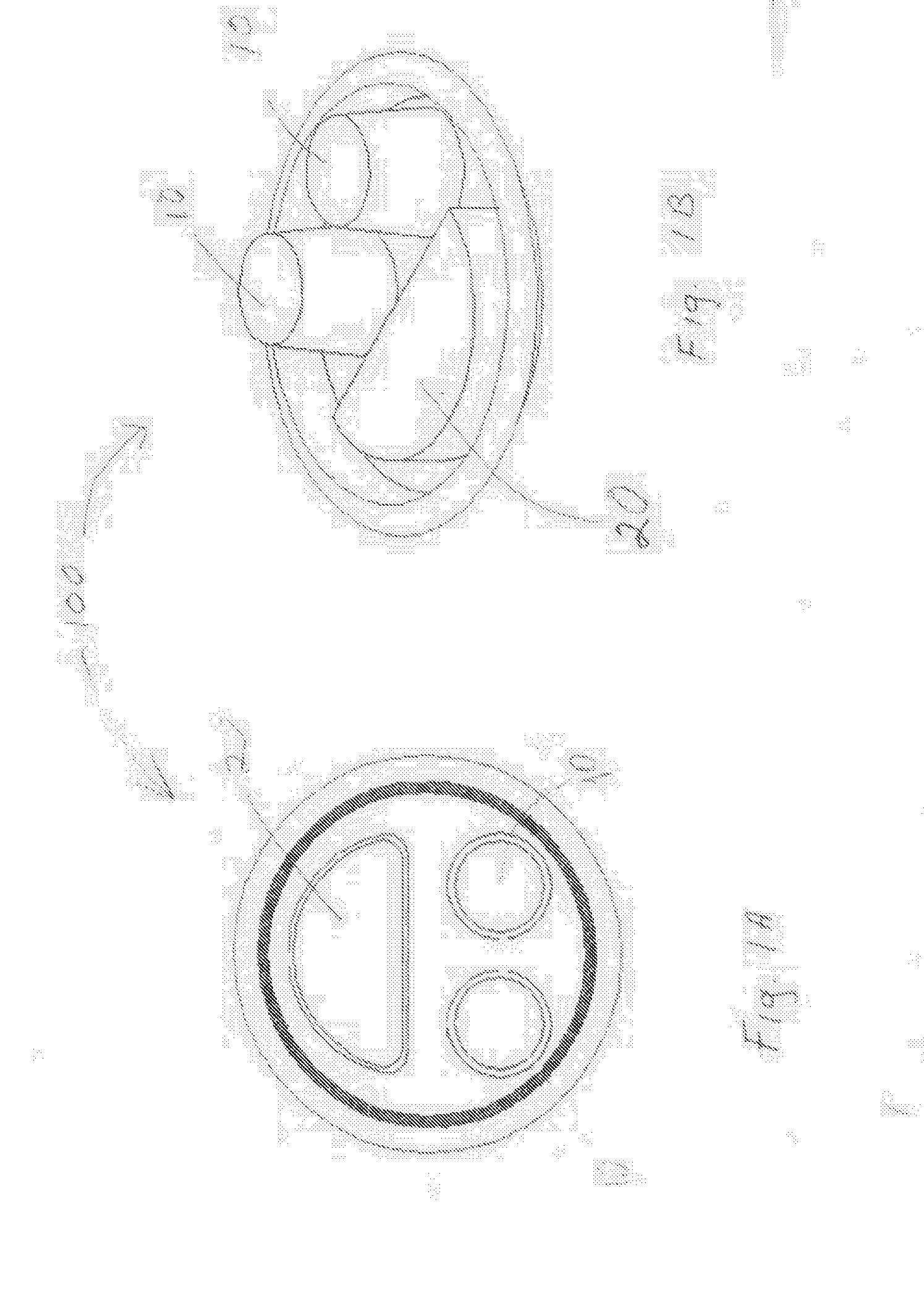

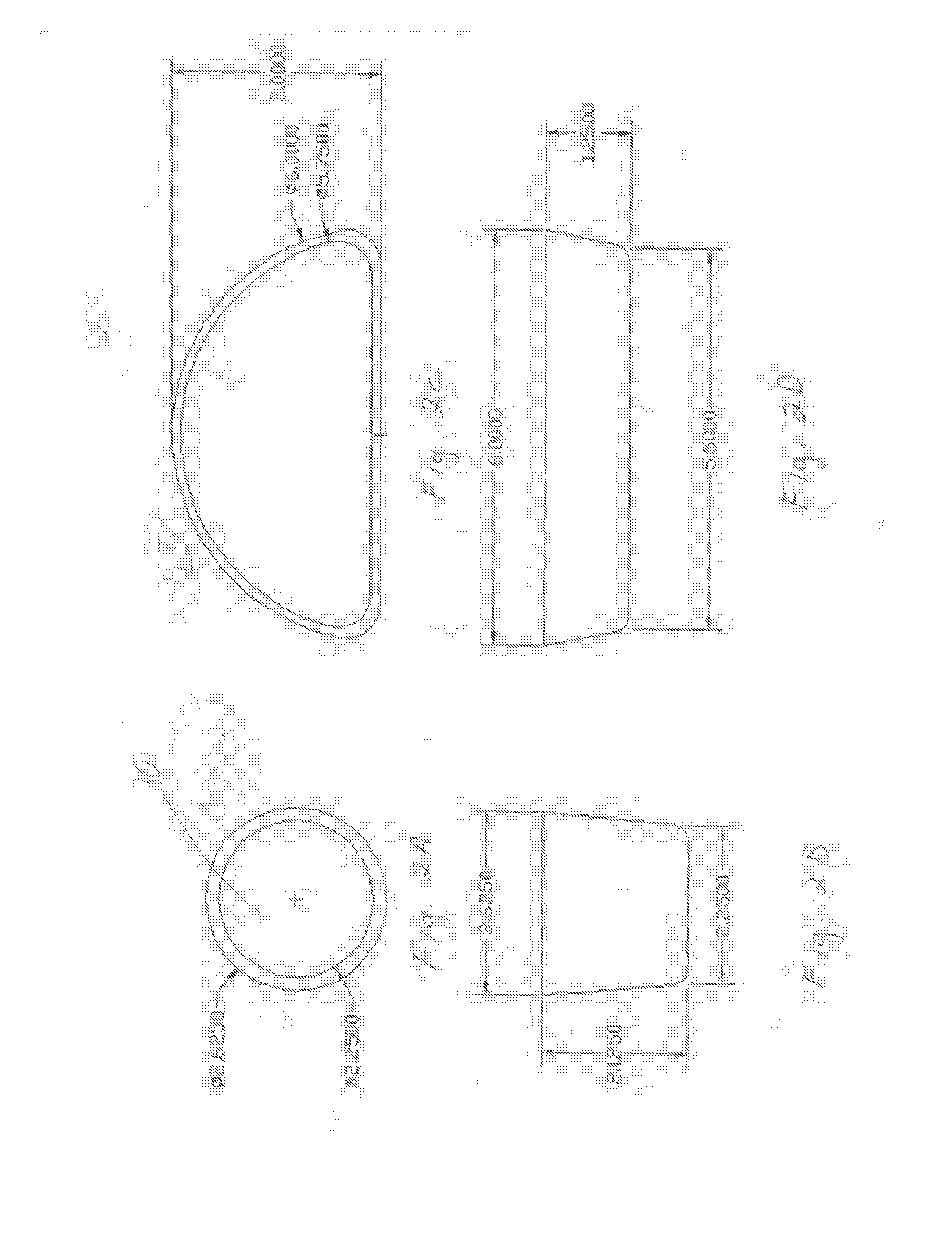

[0027]The present invention in an embodiment provides unique molded flexible meal tray and in another embodiment a rigid meal tray in a new meal component system. The trays provide a number of preshaped cavities or wells into which the components of a meal can be placed. As used herein the terms cavity and well are used in a broad sense to include a space in a tray that can receive product. Although the rigid meal tray could contain any number of preshaped wells, it will generally contain about 2, 3, 4, 5, or more wells having a suitable size such that a satisfying meal can be provided to an individual. Preferably, the food wells on the meal trays have a geometry and a size such that, when heated, all components are simultaneously ready for consumption.

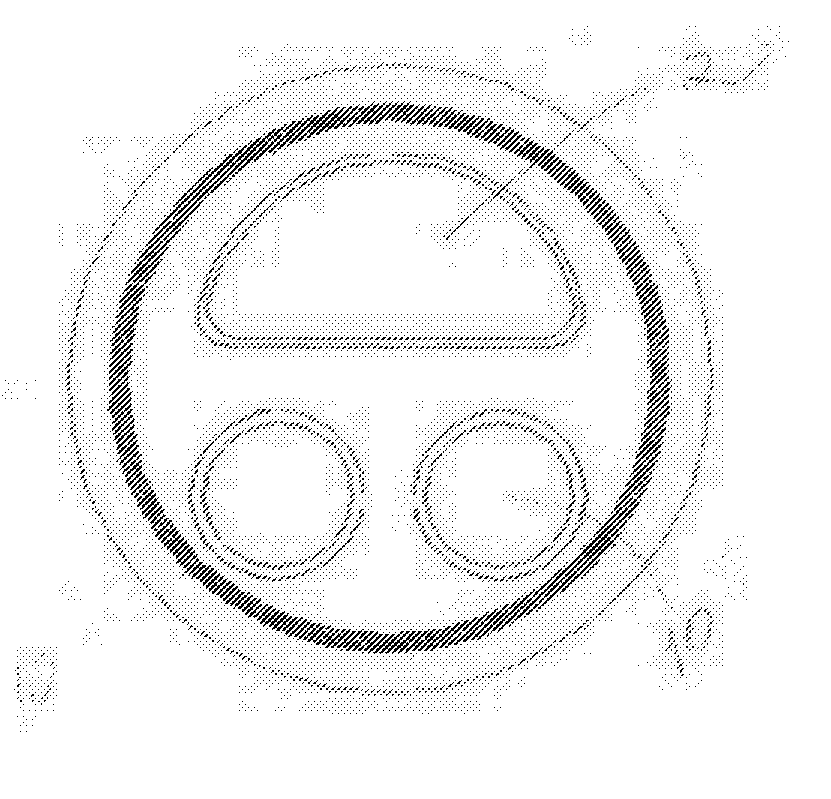

[0028]An embodiment of the rigid meal tray is illustrated in FIGS. 1A and 1B. FIG. 1A illustrates a view of the top surface of a rigid meal tray. Three molds are provided in the tray, including two round molds 10 and a semicircular mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com