Light distribution control method, light distribution control device, and greenhouse using the same

a control device and light distribution technology, applied in the field of passive daylighting, can solve the problems of large portion of light loss due to diffused rays, insufficient symmetry of diffused rays with respect to a light incident at a large azimuth angle, and difficulty in stably satisfying shape and function, etc., and achieve the effect of efficient utilization of diffused ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

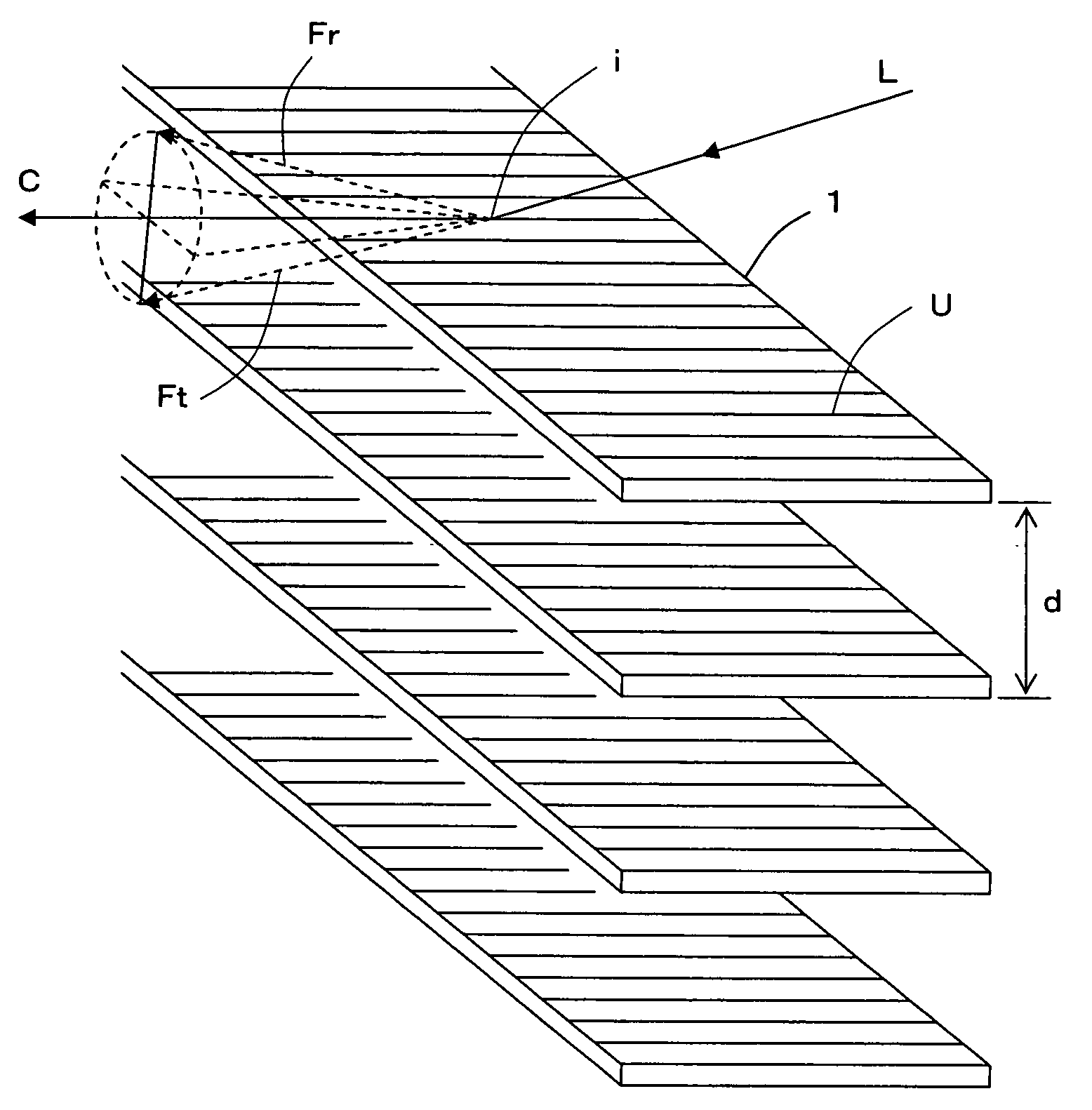

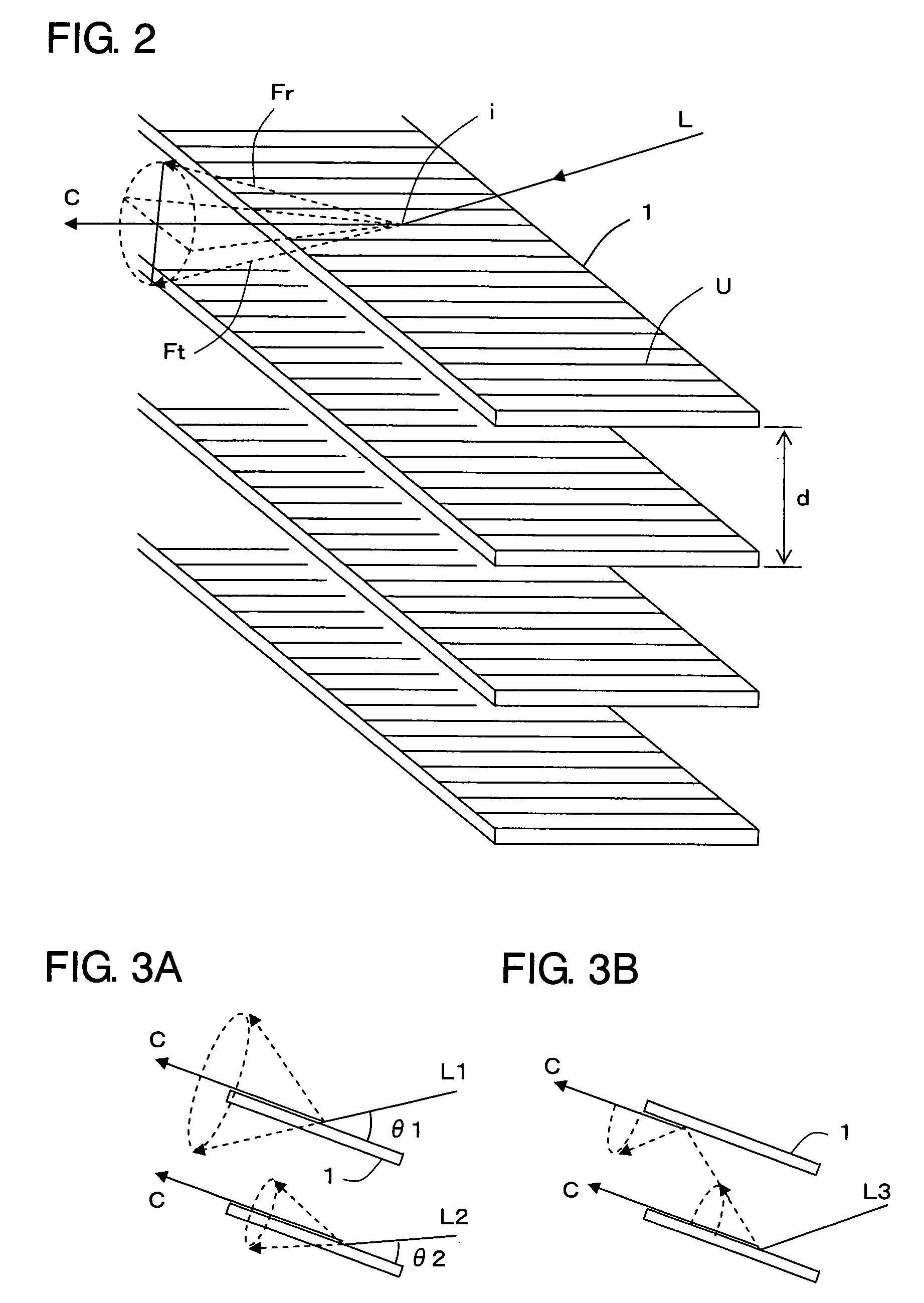

[0045]A light distribution control device according to Embodiment 1 is shown in FIG. 2. The light distribution control device comprises a plurality of structures 1, each of which has a number of ridges U as described above and is formed in a long and thin plate shape or a long and thin film shape. In each of the structures 1, the ridges U are formed so as to cross a longitudinal direction of each of the structures 1, more specifically, to be orthogonal thereto. The structures 1 are arrayed such that the corresponding faces of the adjacent structures 1 are parallel to each other and apart from each other at a predetermined distance as well as the ridges U of the adjacent structures 1 are parallel to each other. In FIG. 2, the ridges U are schematically expressed by simple line segments in order to indicate the direction of formation thereof. In fact, the ridges U, each of which has the cross section forming a portion of a substantial circle and the surface being practically specular,...

embodiment 2

[0053]FIG. 6 shows a light distribution control device according to Embodiment 2. This light distribution control device has an almost the same structure as the light distribution control device according to Embodiment 1 but further includes an adjusting mechanism 2 for adjusting an angle of the plurality of structures 1 which are parallel to one another. A mechanism for adjusting a tilt of a plurality of blades of a general-purpose blind can be used as the adjusting mechanism 2.

[0054]Since the adjusting mechanism 2 is provided, the angle of the respective structures 1 can be easily adjusted corresponding to the desired direction for light distribution.

embodiment 3

[0055]While each of the structures 1 used in the light distribution control device according to Embodiment 1 has a plate shape, it is possible to use a structure 1 whose cross section orthogonal to a longitudinal direction thereof has a bent shape or a V-shape as shown in FIG. 7. That is, the structure 1 comprises an outside portion 3 and an inside portion 4 which are divided along the longitudinal direction, wherein the ridges U are formed on each of the surface 3a of the outside portion 3 and the surface 4a of the inside portion 4 in a direction orthogonal to the longitudinal direction. The structure 1 has both optical transparency and optical reflectivity.

[0056]As shown in FIG. 8, a plurality of structures 1, each of whose cross section has a bent shape, are arrayed in parallel and apart from each other at a predetermined distance to construct the light distribution control device according to Embodiment 3.

[0057]For example, the light distribution control device is placed such th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com