Heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

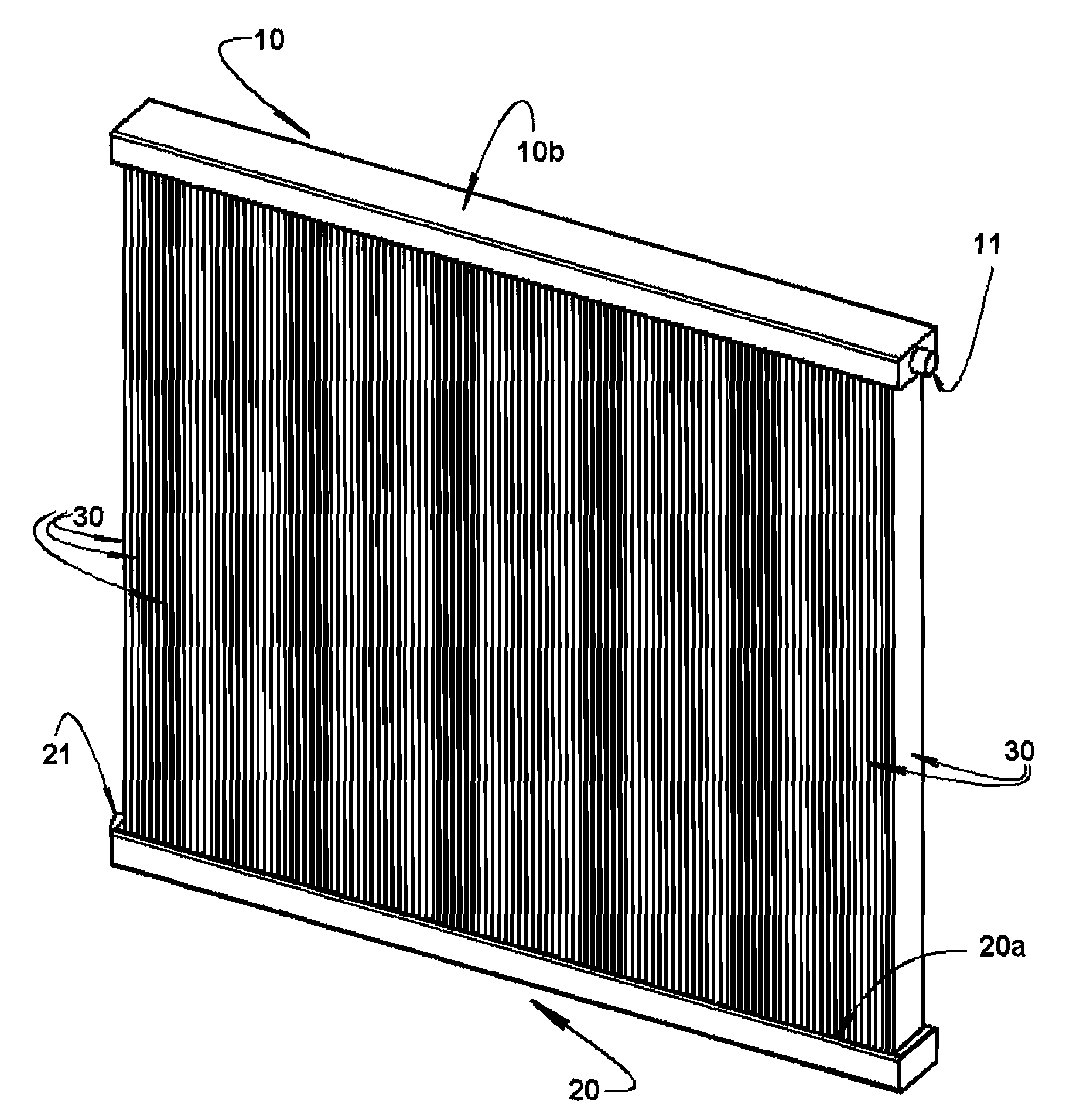

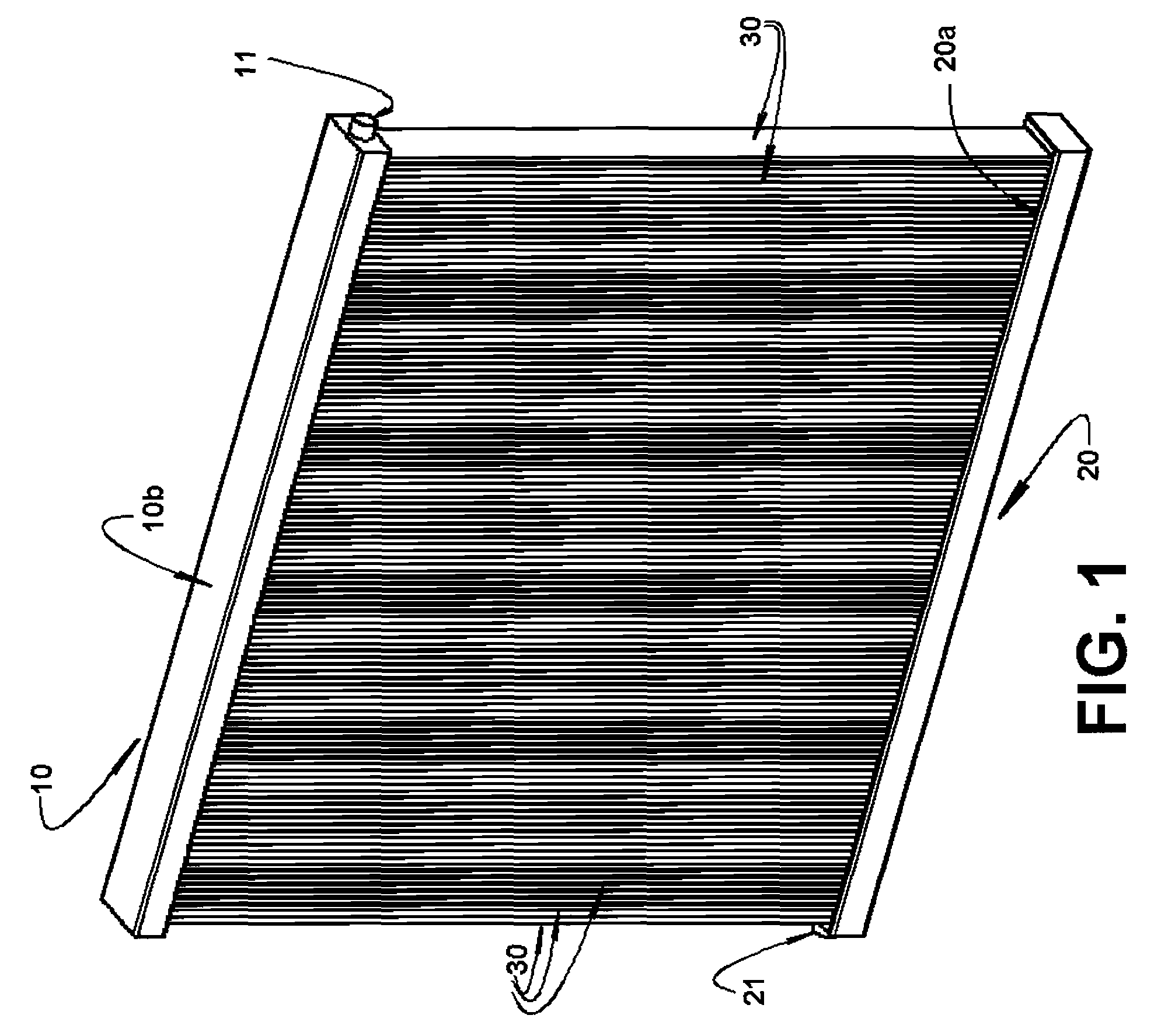

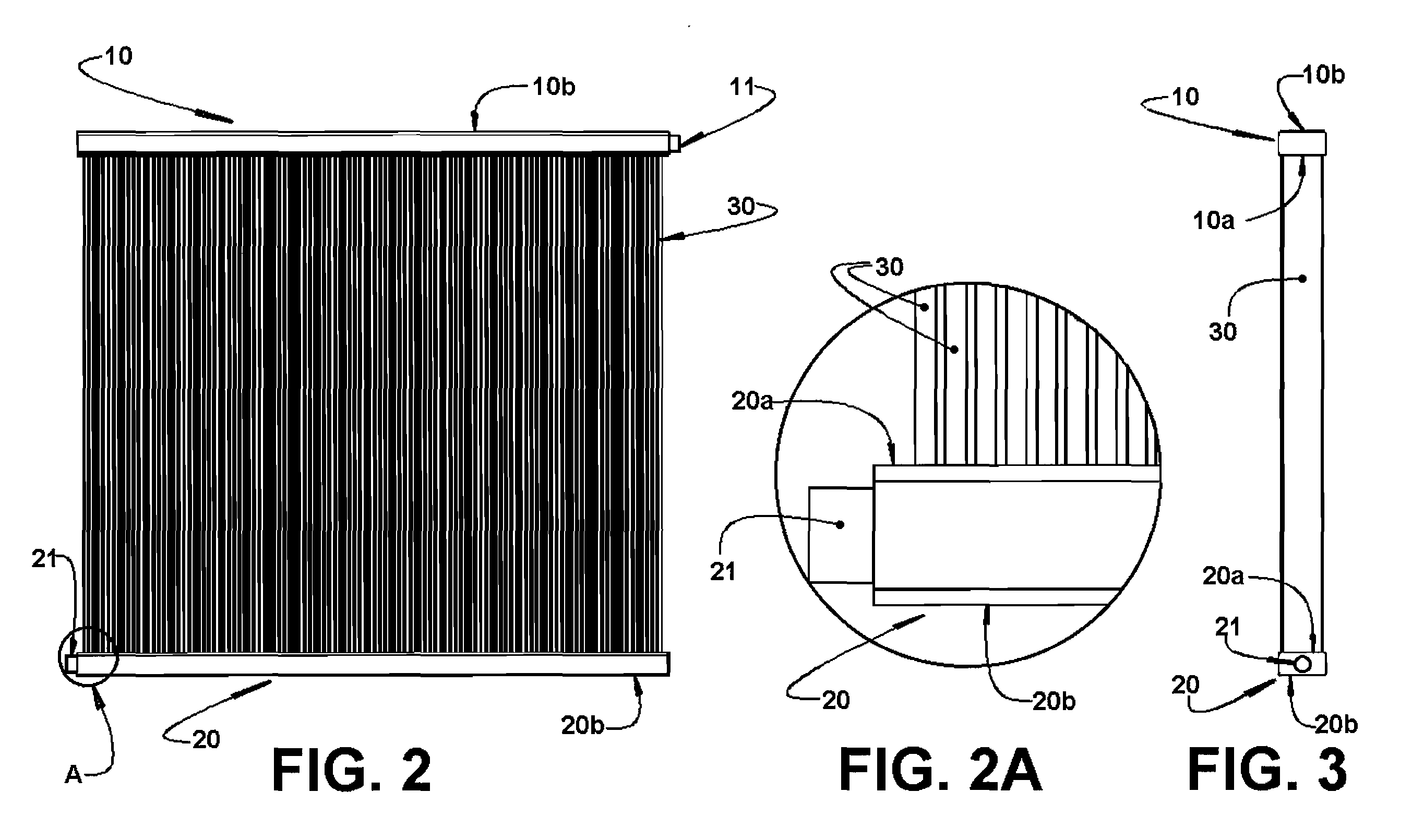

[0021]As already previously mentioned and illustrated in the enclosed drawings, the invention refers to the construction of a heat exchanger to be used as a condenser or as an evaporator in several applications, particularly in air conditioner appliances, said heat exchanger being of the single circuit type.

[0022]According to the present invention, the heat exchanger comprises an upper tubular head element 10 and a lower tubular head element 20, constructed in any adequate material, such as for example, carbon steel, stainless steel, thermoplastic material, etc., and which are horizontally arranged and have their ends closed, so that each tubular head element defines a tube extension whose cross section can vary according to the heat exchanger project. In the embodiment illustrated in the drawings, the upper tubular head element 10 and the lower tubular head element 20 present a rectangular cross section, having an inner longitudinal wall 10a, 20a turned to the heat exchanger struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com