Preventing and Reducing Biofilm Formation and Planktonic Proliferation

a biofilm and planktonic technology, applied in biocide, biological water/sewage treatment, disinfectants, etc., can solve the problems of affecting the flushing effect,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

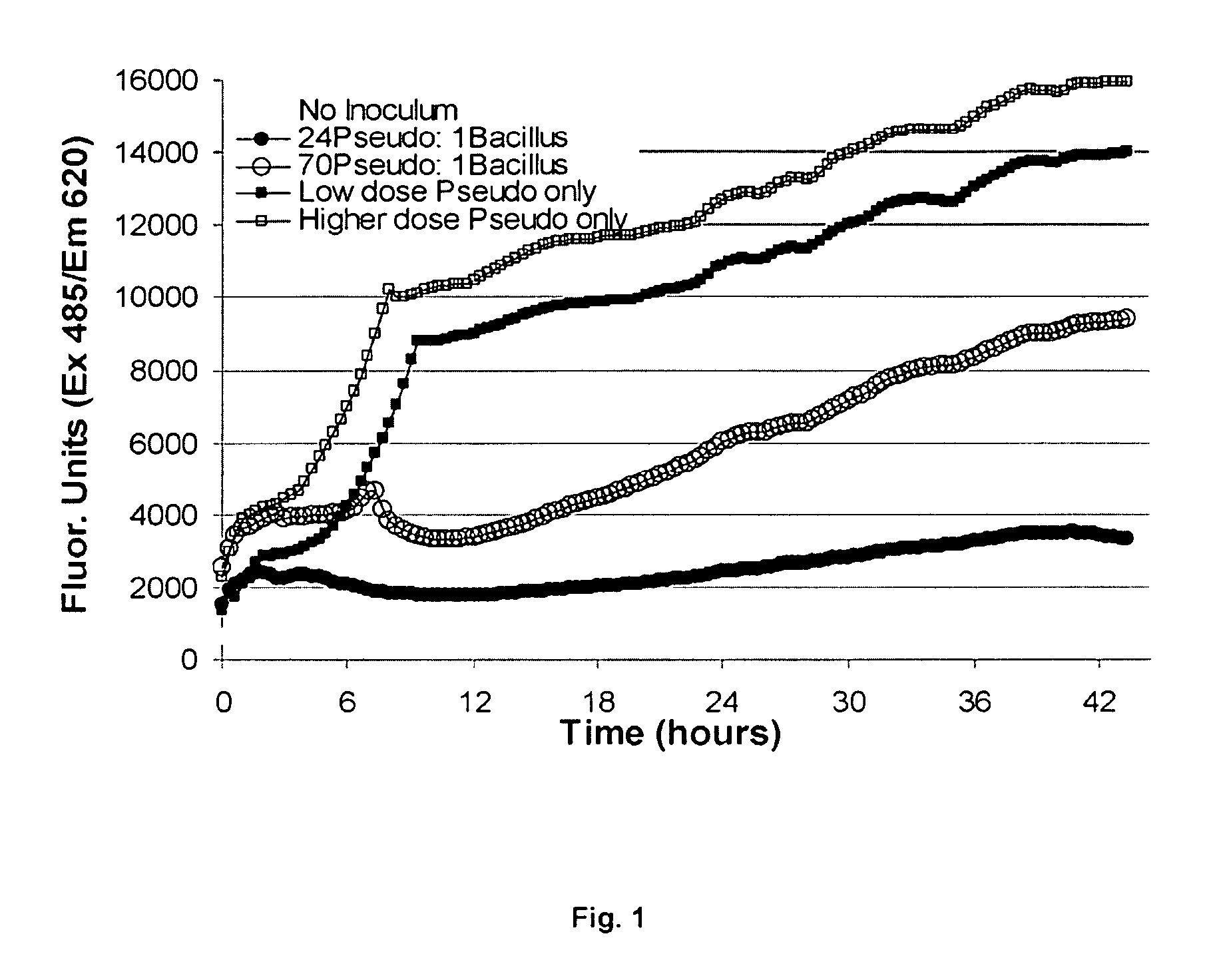

Planktonic Proliferation of Pseudomonas in the Presence of Bacillus Blend (6BB)—Fluorescent Microtiter Plate (FMP)

[0144]Wells of a 96-microtiter plate were filled with 200 microL of Plate Count Broth (Difco DF0751-17-2) and inoculated with a Pseudomonas aeruginosa strain equipped with a plasmid expressing green fluorescent protein constitutively. A blend of six Bacillus spp. (6BB) was added to the wells. Initial dose of Pseudomonas was either 2.4×108 or 4.8×108 cfu / mL while Bacillus spp. dose was 6.8×106 to 1.0×107 cfu / mL resulting in Pseudomonas:Bacillus ratios of 24:1 and 70:1. Microtiter plates were tracked with a fluorescent kinetic microtiter plate reader (BioTek Synergy HT-I) with incubation at 21° C. and fluorescent reads at 485 / 20 nm excitation, 528 / 20 nm emission, every 20 minutes for 43 hours. Resulting fluorescence kinetic curves showed Bacillus-dose dependent suppression of gfp fluorescence (i.e., Pseudomonas population suppression) (FIG. 1).

example 2

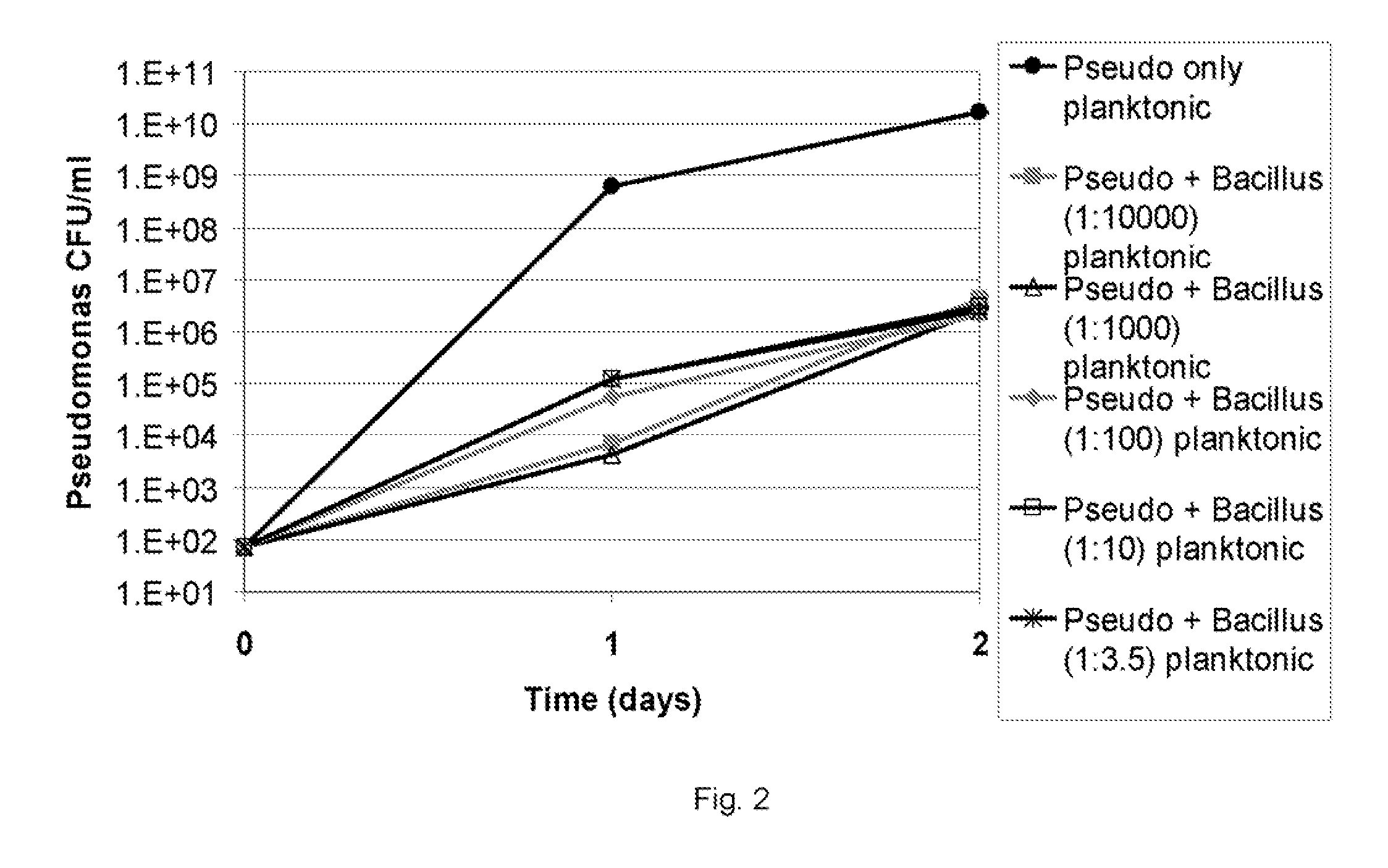

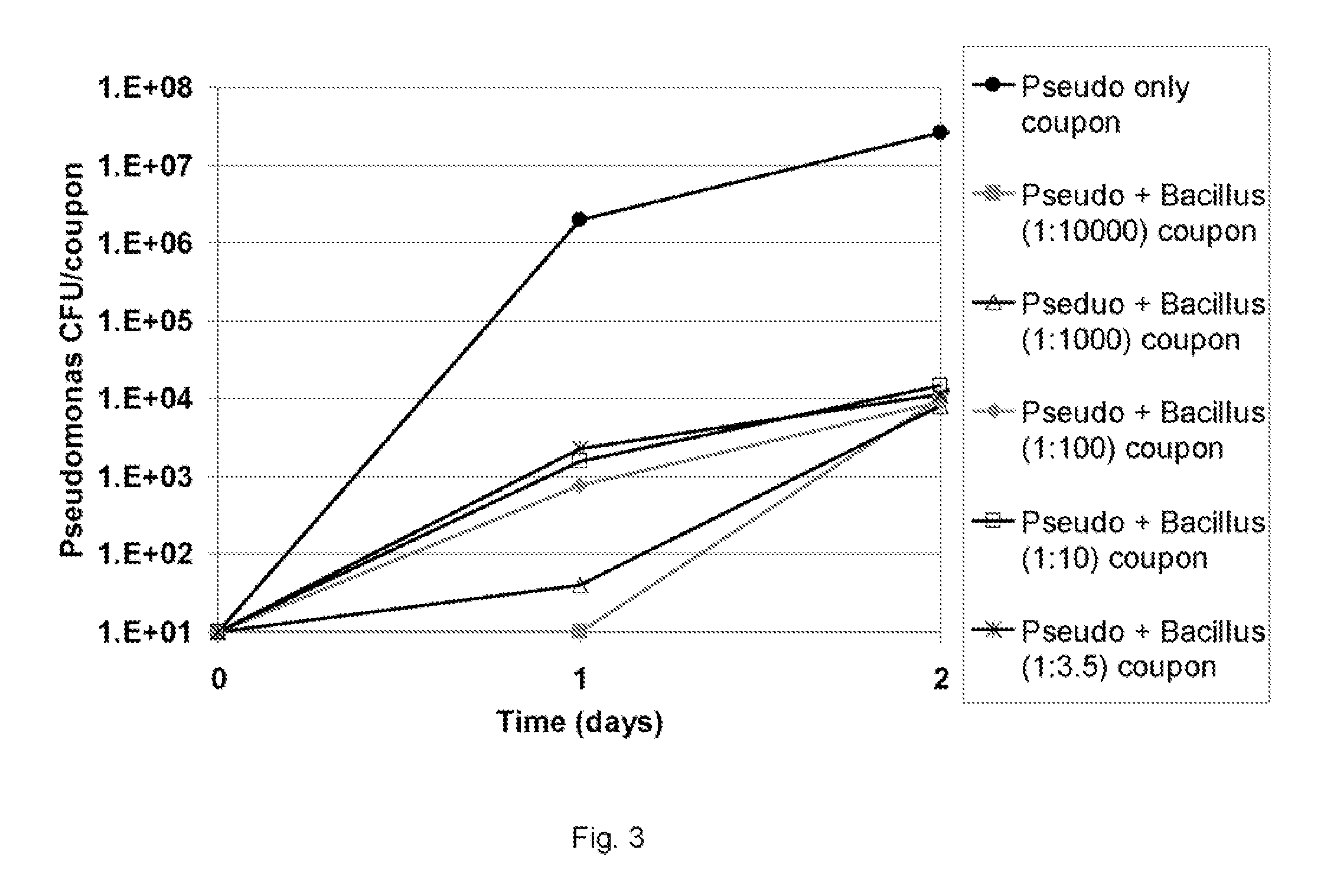

[0145]Reduced Pseudomonas Biofilm Formation and Planktonic Proliferation in Presence of Bacillus blend—Test Tube+Coupon Biocontrol (TTCBC)

[0146]A polycarbonate holder (Biosurfaces Technology) with three porcelain coupons (Tyler Research Instruments Corp., Edmonton, Alberta) was inserted into a wide-mouth test tube (Fisher cat#NC9421998) and 50 mL Plate Count Broth (Difco DF0751-17-2) made according to label instructions was added and autoclaved. Tubes were inoculated with a blend of Bacillus spores and incubated at 28° C. with mild shaking overnight thereby allowing germination. Initial dose of Bacillus spores ranged from 2.6×102 to 7.8×105 cfu / mL.

[0147]The following day, a Pseudomonas aeruginosa strain with gfp expression was added to the tubes at a concentration of 70 cfu / ml resulting in Pseudomonas:Bacillus initial inoculum ratios ranging from 1:3.5 to 1:10,000. Following additional 24 and 48 hour periods of incubation, the tubes were destructively sampled by scraping each coupon...

example 3

Reduced Pseudomonas Biofilm Formation and Planktonic Proliferation in Presence of Bacillus Isolates—Test Tube+Coupon Biocontrol (TTCBC)

[0148]A polycarbonate holder (Biosurfaces Technology) with three porcelain coupons (Tyler Research Instruments Corp., Edmonton, Alberta) was inserted into a wide-mouth test tube (Fisher cat#NC9421998) and 50 mL Plate Count Broth (Difco DF0751-17-2) made according to label instructions was added and autoclaved. Each tube was inoculated with an overnight vegetative cell culture of an individual Bacillus candidate and an overnight culture of Pseudomonas aeruginosa equipped with a gfp plasmid. The tubes were incubated at 28° C. with mild shaking. Initial dose of Bacillus cells was in the range of 1.0×103 to 8.2×105 cfu / mL and initial dose of Pseudomonas was approximately 1×103 to 1×105. The Pseudomonas to Bacillus ratios ranged from 1:2 to 1:147.

[0149]At time points 24 and 48 hours into incubation, the tubes were destructively sampled by scraping each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com