Floating structure

a floating structure and structure technology, applied in the direction of floating buildings, pontoons, vessel construction, etc., can solve the problems of low wrap resistance of longitudinal bases, relatively high material costs, and inability to approximate arbitrary forms of known bases, so as to achieve the effect of reducing wave resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

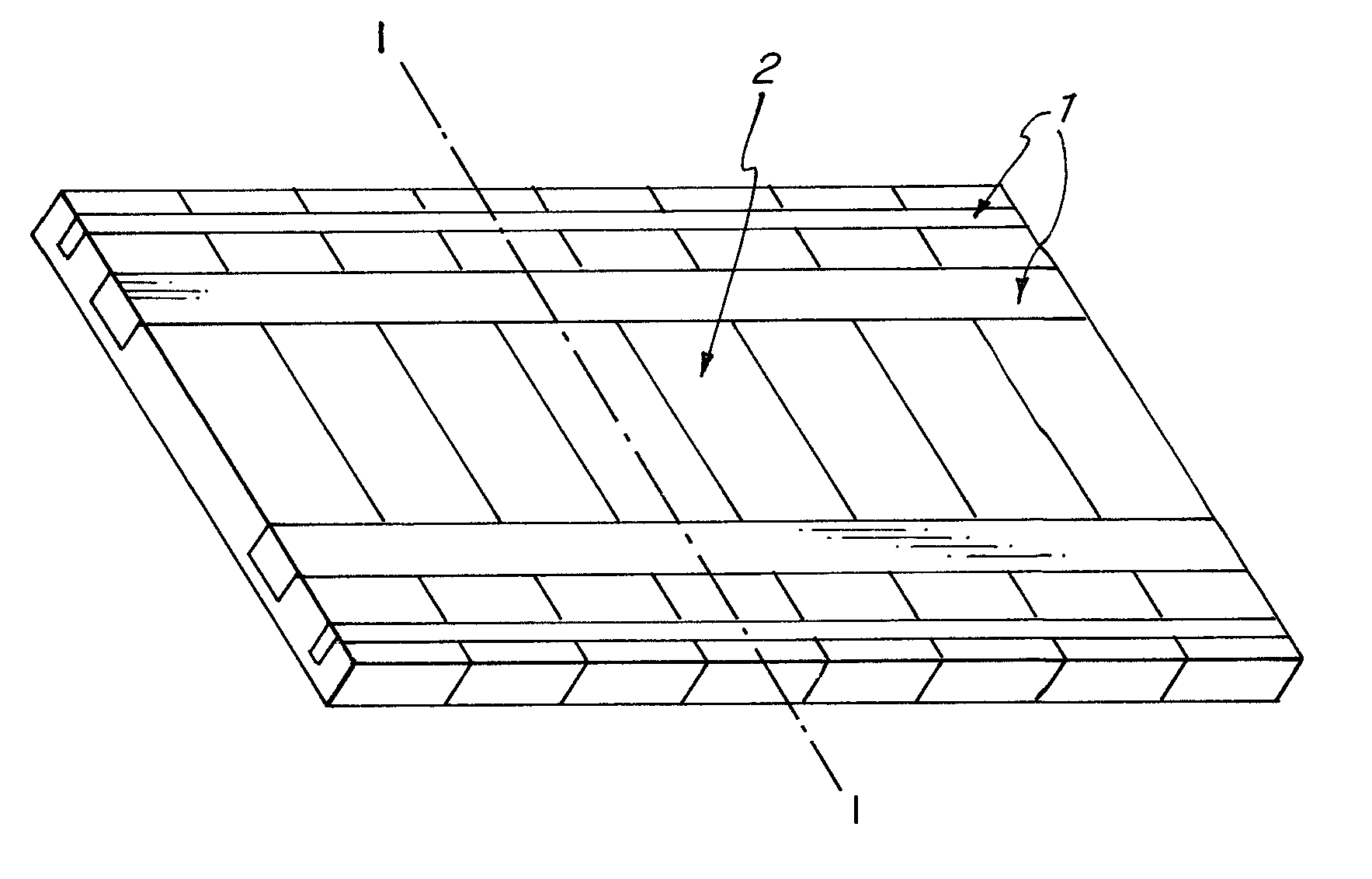

[0025]FIG. 1 is a spatial view of a floatable structure showing the floatable single bodies 2 and the connecting members 1. A plurality of floatable single bodies 2 is provided with cut-outs which are aligned perpendicular to its longer extent and parallel to the water surface. The cut-outs are arranged so that the connecting members 1 can be inserted into them, which then provide for a rigid connection of the single bodies 2. For reduction of wrapping in the floatable structure, preferably more than two, namely for example four connecting elements 1 are used as shown here. Those extend preferably over the total length of the structure.

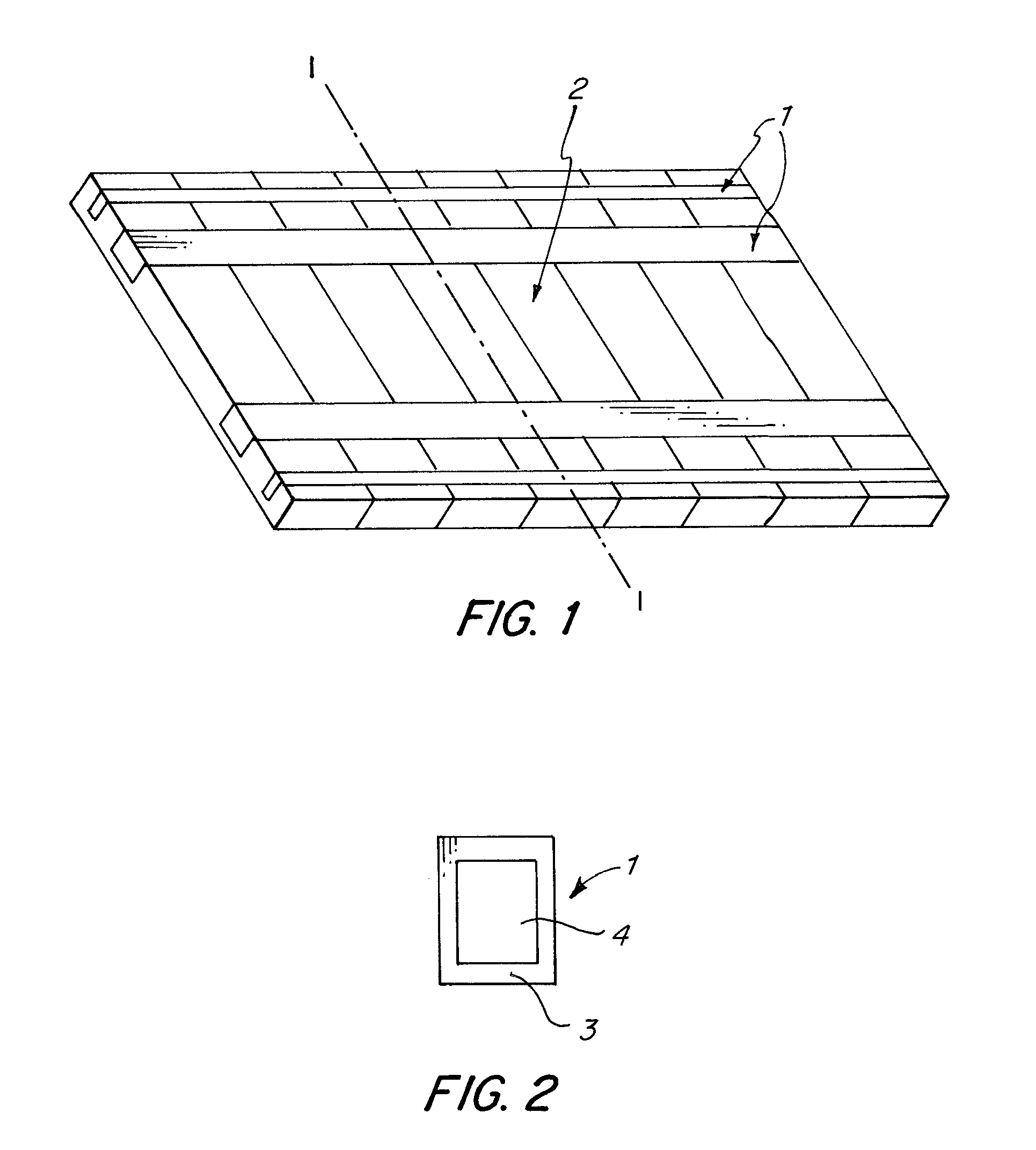

[0026]FIG. 2 is a cross-sectional view of a connecting member 1 of FIG. 1 which shows a box profile 3. The box profile 3 is preferably manufactured of ferroconcrete. First, a U-form is made in the cut-outs of the single bodies 2. The upper plate of the box profile 3 is made later on, which allows to insert styrofoam 4 into the inner space of the box p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com