Heat storage tank

a technology of heat storage tank and heat exchanger, which is applied in the direction of indirect heat exchanger, machine/engine, light and heating apparatus, etc., can solve the problems of increasing cost and achieve the effect of increasing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

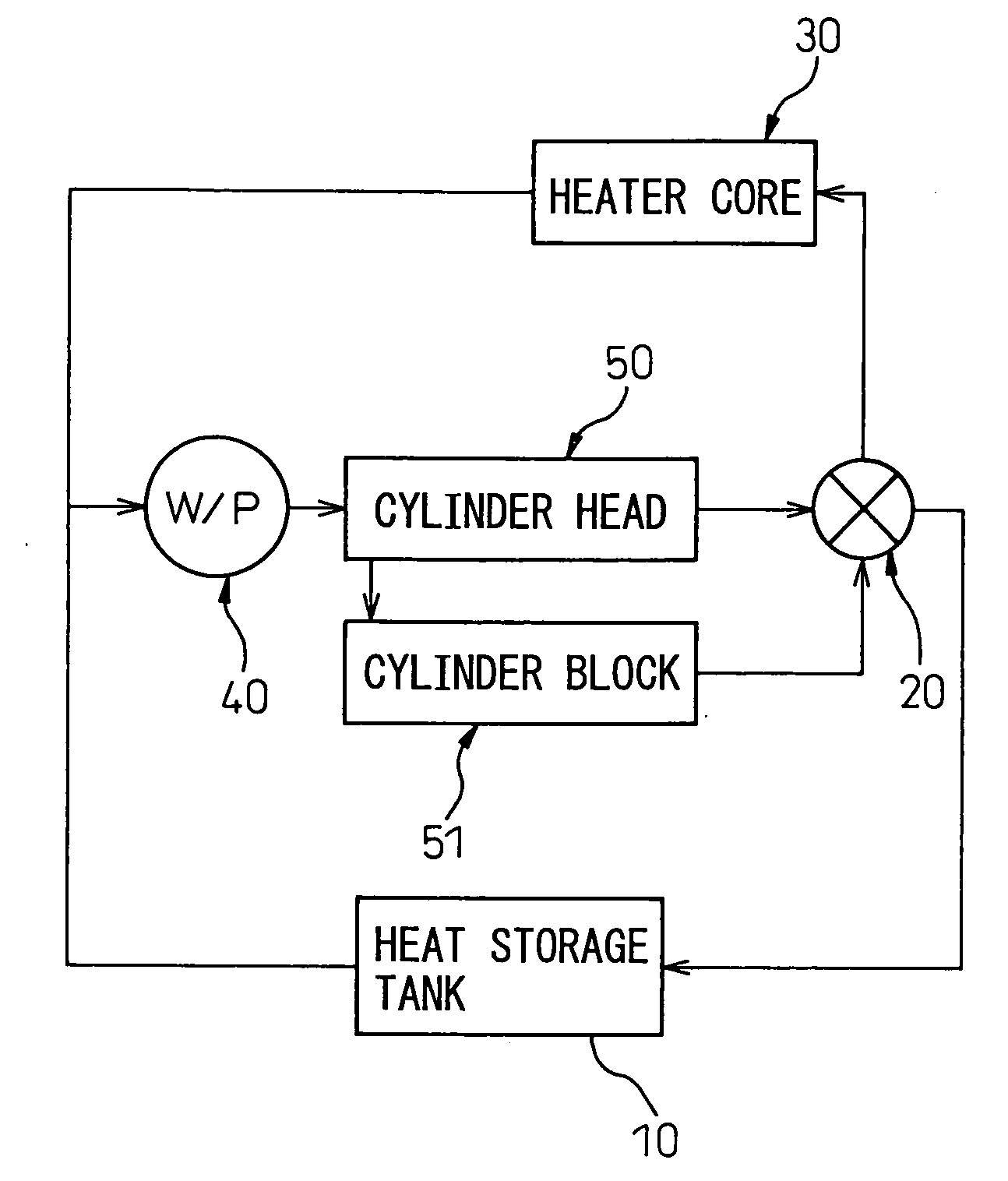

[0025]FIG. 1 shows a configuration of the cooling water circuit using the vehicle heat storage tank according to an embodiment of the invention.

[0026]The cooling water circuit includes a heat storage tank 10, a four-way valve 20, a heater core 30 and an electrically-operated pump 40. Heat storage tank 10 is for insulating and storing the engine cooling water. Four-way valve 20 connects the outlet side of one of a cylinder head 50 and a cylinder block 51 of the engine to the inlet side of at least one of heater core 30 and heat storage tank 10.

[0027]Heater core 30, which makes up a vehicle air conditioning system, is a heat exchanger for heating the air with the engine cooling water. Electrically-operated pump 40 is a circulation pump for supplying the engine cooling water toward the inlet side of each of cylinder head 50 and cylinder block 51.

[0028]In the cooling water circuit, a connection is established only between the outlet side of cylinder block 51 and the inlet side of heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com