Dual flow fan heat sink application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

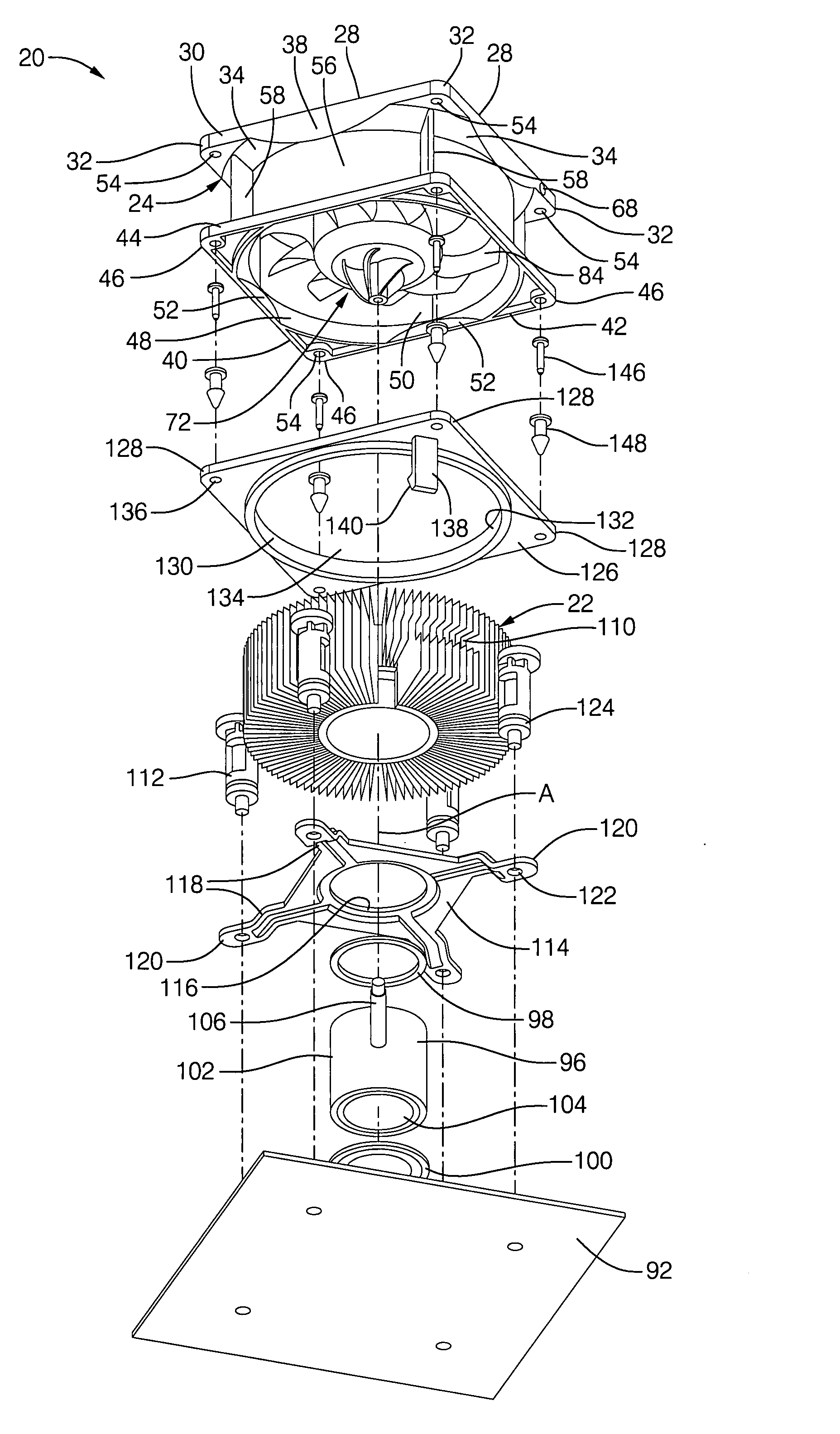

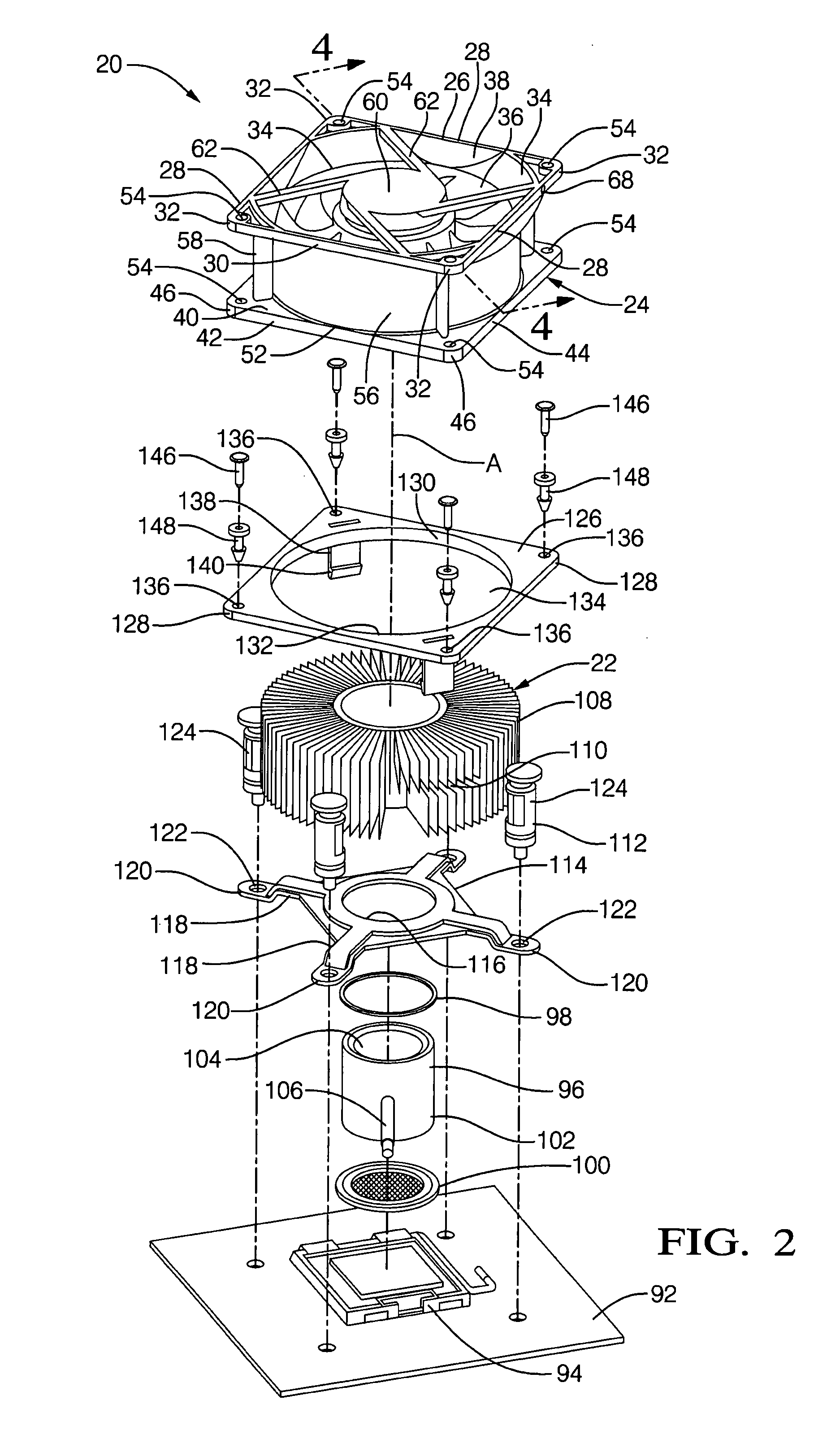

Image

Examples

second embodiment

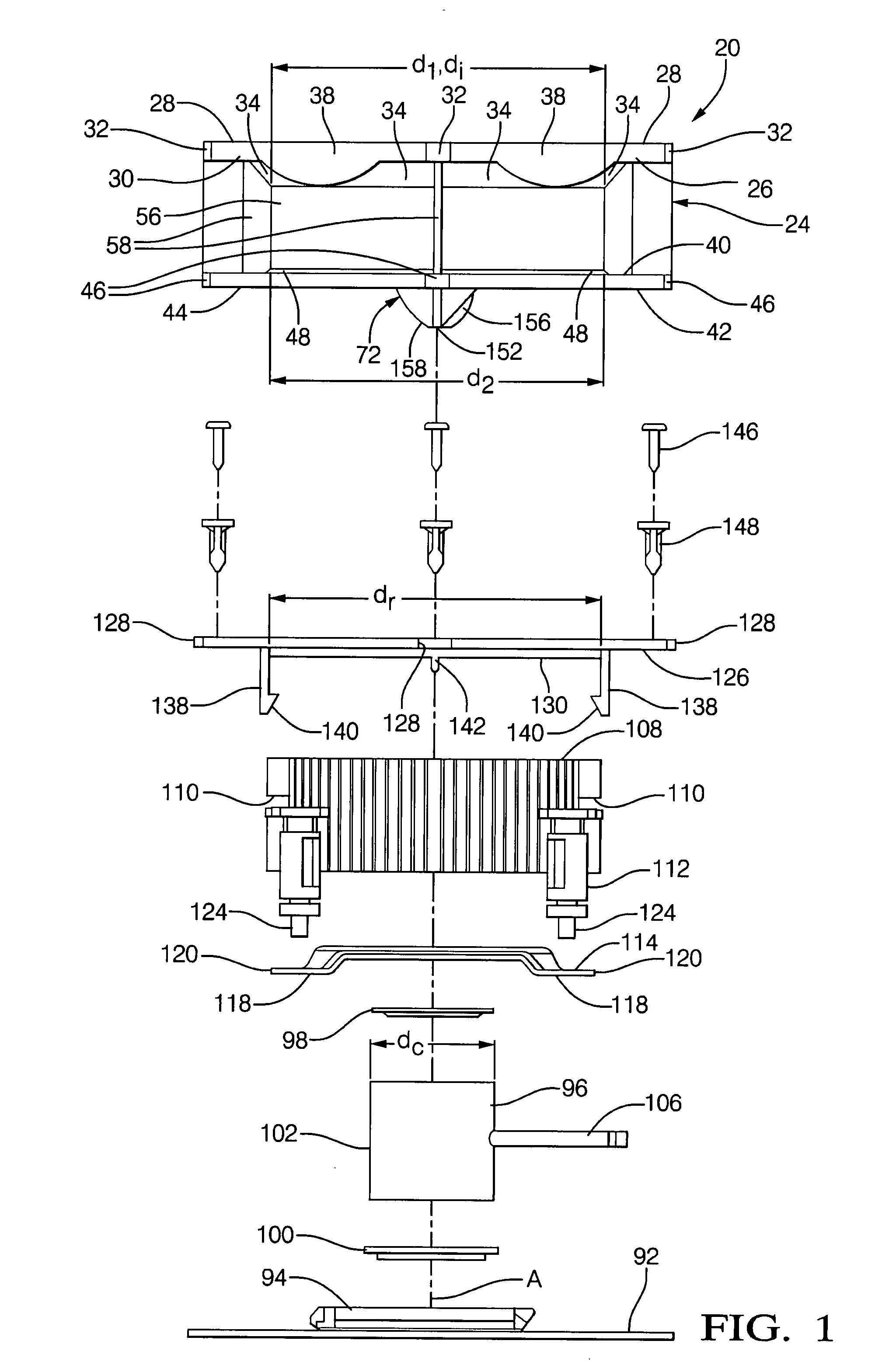

[0038]In the subject invention, each of the air vanes 156 extend axially from the hub bottom 76 a shorter distance adjacent the tube 152 than adjacent the gap 134. The air vanes 156 move the air over the top core portion 98 and through the air passage 154 to establish communication between the channels 90 and the air cavity 150.

third embodiment

[0039]In the subject invention, a shaft 160 that is hollow extends along the axis A and through the motor assembly 64 to the tube 152 to move air therethrough and to establish communication between the shaft 160 and the air cavity 150.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com