Wind energy plant tower

a technology for wind energy plants and towers, applied in wind energy generation, motors, mechanical equipment, etc., can solve the problems of ever-increasing problems affecting the operation of wind energy plants, the installation of towers, etc., and achieve the effect of simplifying the manufacture of wall sections, uniform connection, and significantly simplifying the production of wall sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]While this invention may be embodied in many different forms, there are described in detail herein a specific preferred embodiment of the invention. This description is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiment illustrated

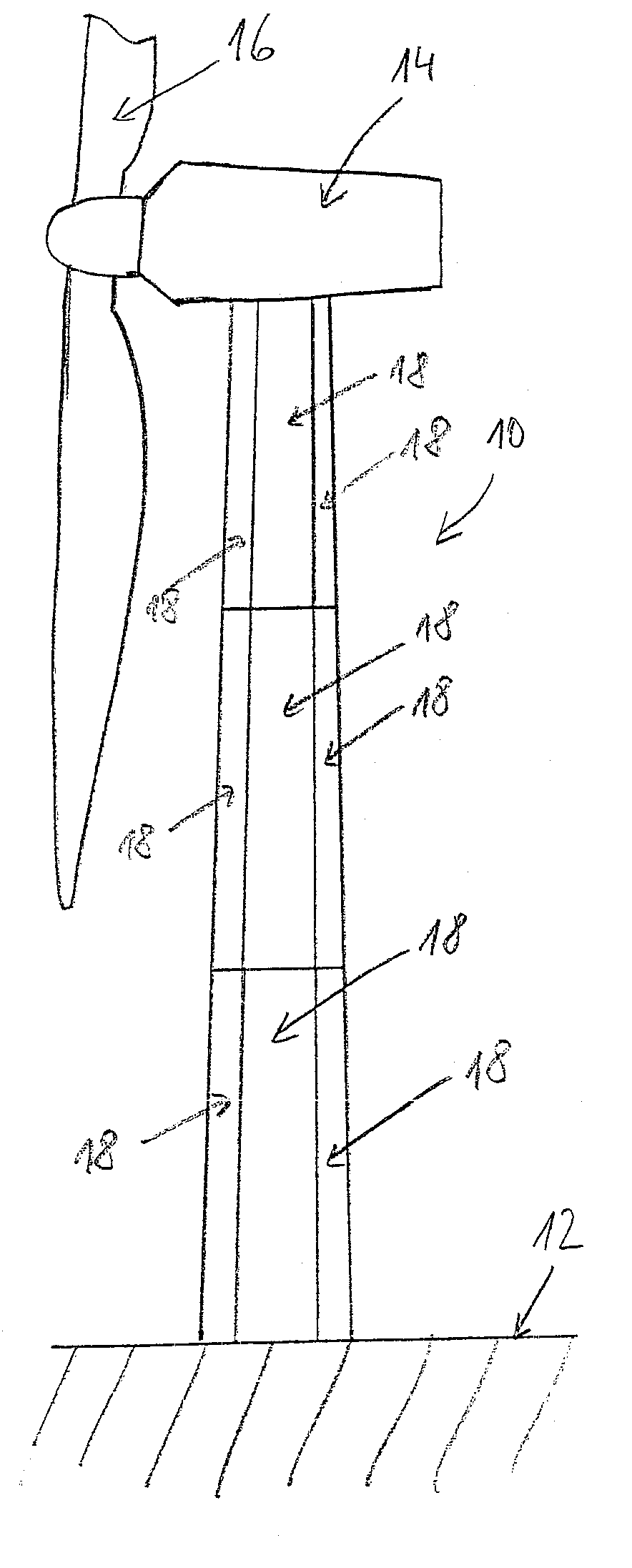

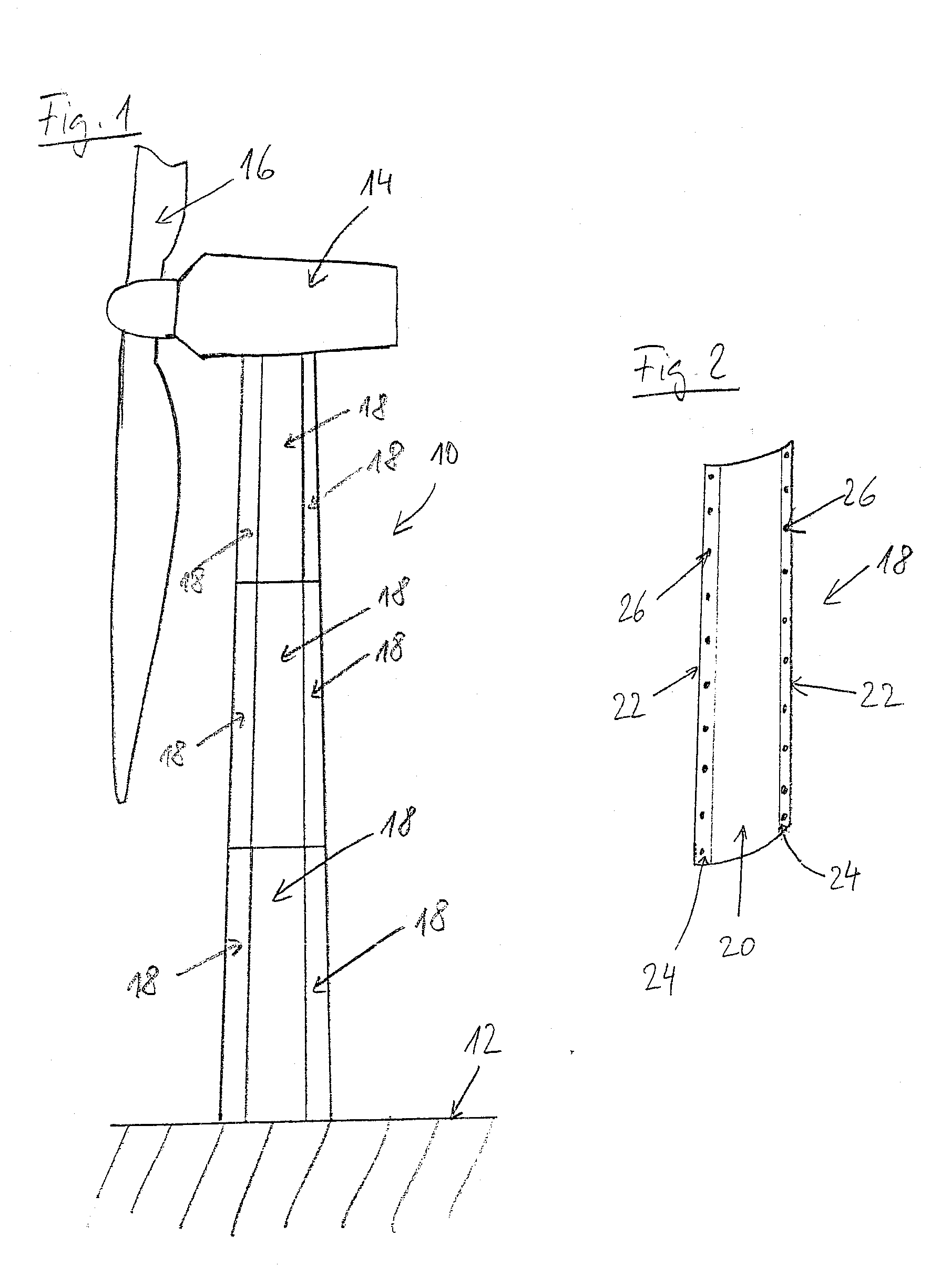

[0035]In the simplified depiction of FIG. 1, one recognizes a wind energy plant tower 10, which is anchored in a foundation 12 and carries a nacelle 14 of the wind energy plant. On the nacelle, the indicated rotor 16 of the wind energy plant is fastened. The tower 10 is composed of a plurality of wall sections 18. In the example, an equal number of wall sections 18 constitute one of three tower segments at a time, which are arranged on top of each other. In this, each wall section extends across the height of one tower segment in the vertical direction. Depending on the magnitude of the tower and other general conditions, a greater or a smaller number of tower segments can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com