Air Gap Servo for Optical Recording

a technology of optical recording and air gap, which is applied in the direction of data recording, instruments, and disposition/mounting of heads, etc., can solve the problems of only available air gap error signals, slow pull-in procedure, and crash of head-discs, and achieve the effect of low risk of head-disc crash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

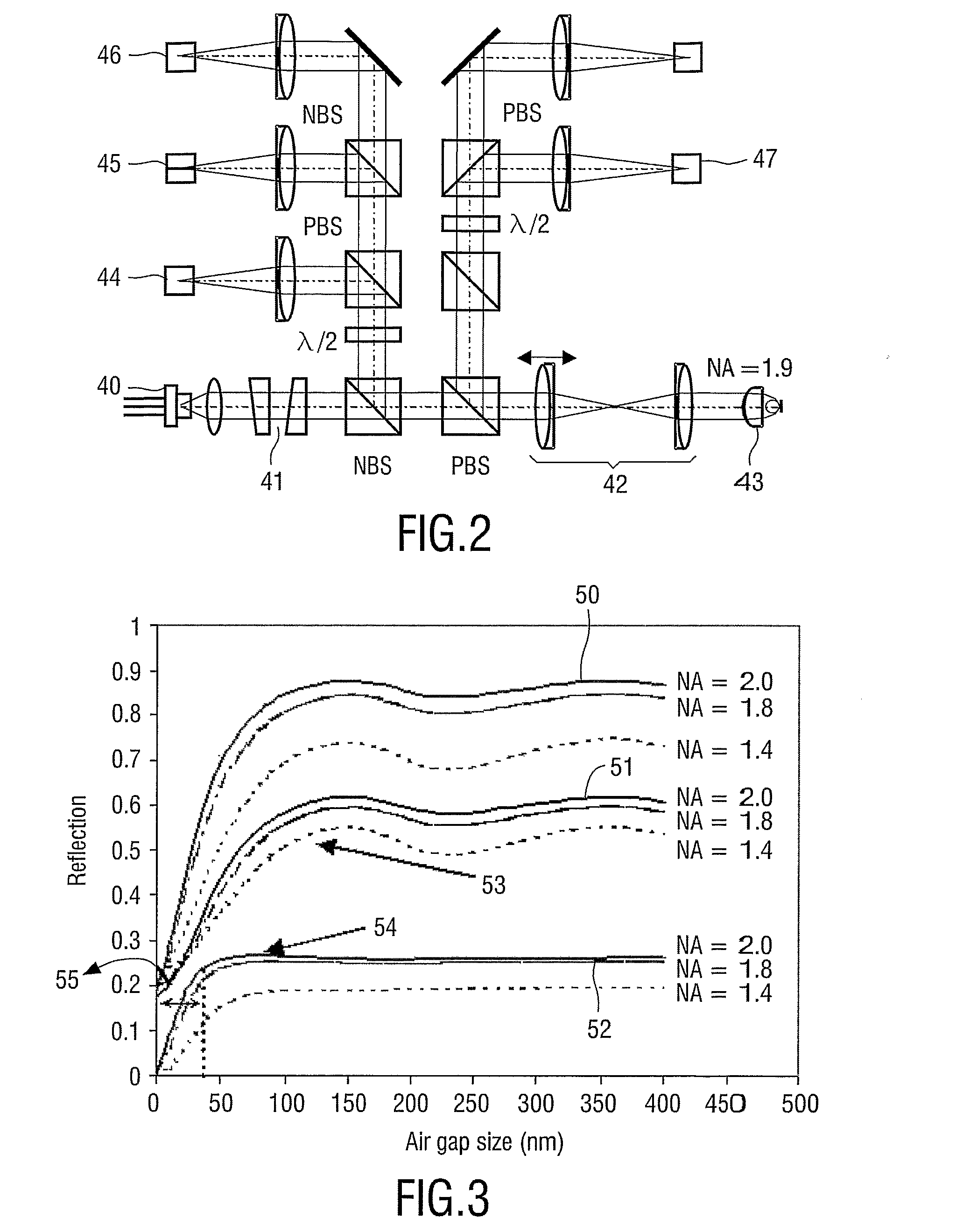

[0029]An optical recording system using a near field optical head, which consists of an aspherical lens and a Solid Immersion Lens (SIL), has been proposed as a technology to read out 50 Gbyte or more on a 12 cm optical disc. In this system, it is essential to maintain an air gap between the SIL bottom surface and the disc constantly in a near field position where the evanescent wave is detectable. Thereto an air gap servo system is required

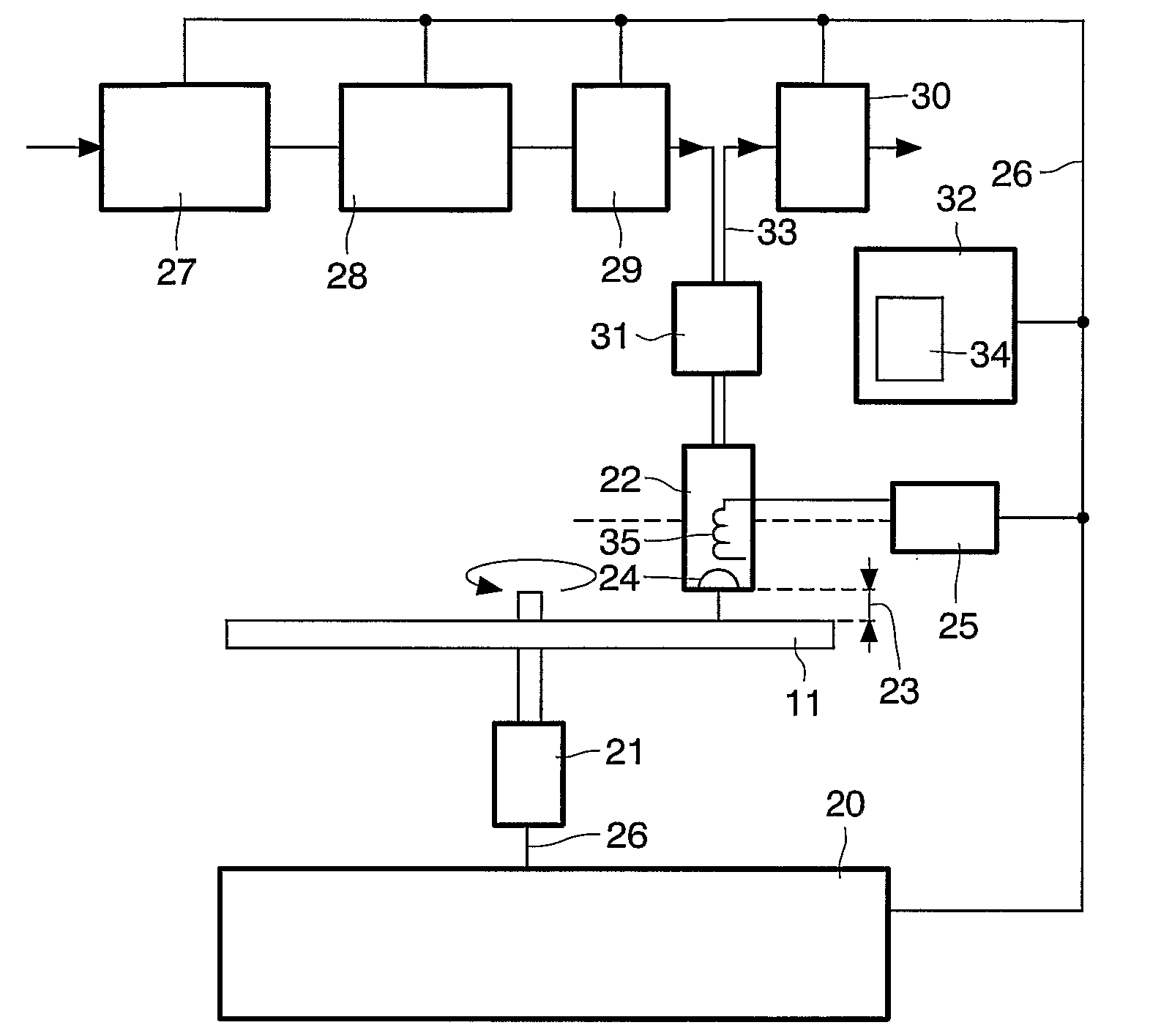

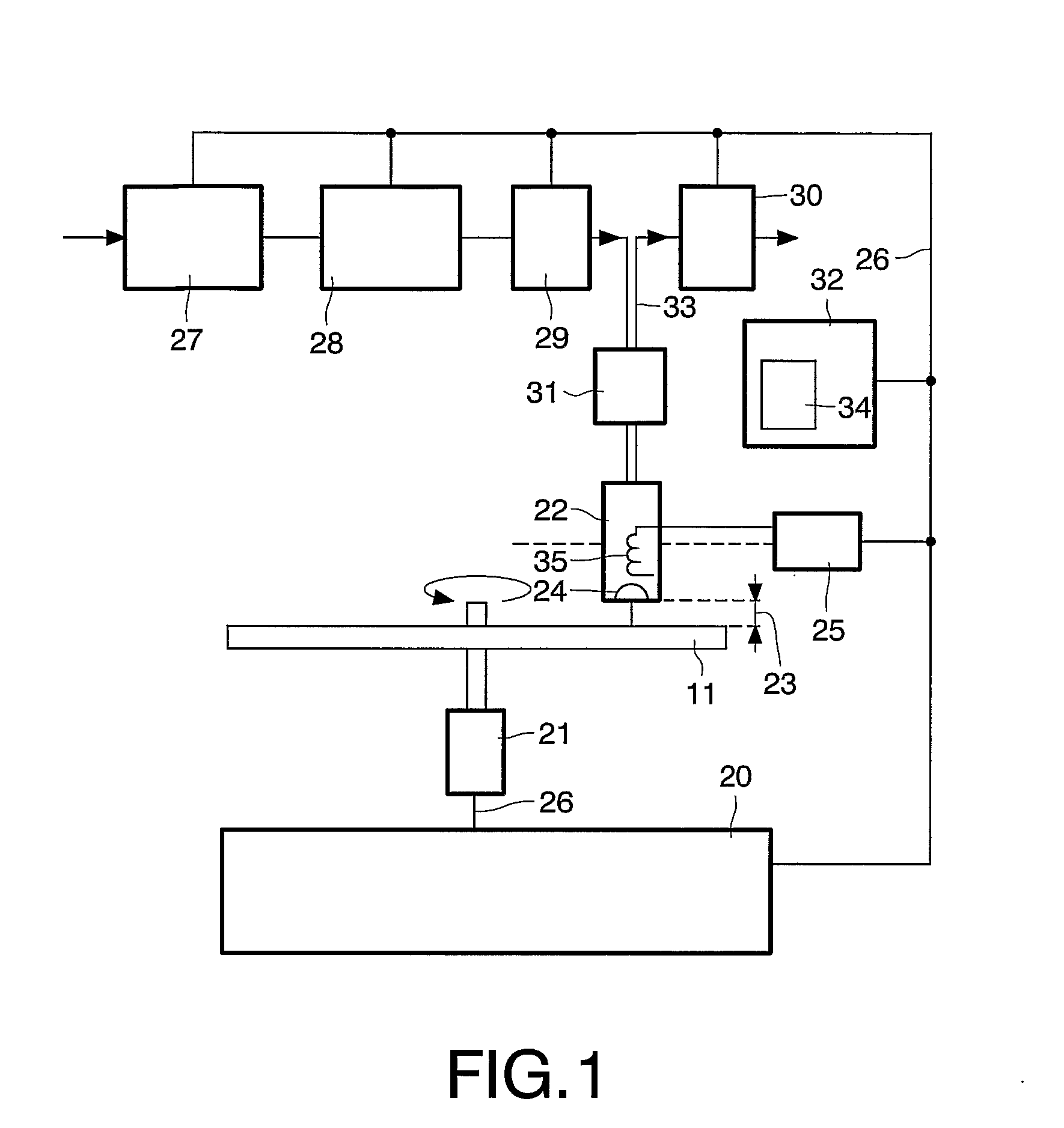

[0030]FIG. 1 shows an optical recording device having an air gap servo. The device is for optically reading and / or recording data on a record carrier 11 via a near field optical system. The near field optical system is known as such, inter alia from doc[1] and from K. Saito, et. al, “Readout Method for Read Only Memory Signal and Air Gap Control Signal in a Near Field Optical Disc System,” Jpn. J. Appl. Phys. Vol. 41 (2002), pp. 1898-1902 (further referred to as doc[2]). The disc-shaped record carrier 11 has a track 9 arranged as a spiral or annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com