Long-Lasting Flame Colorant Composition, Device, And Method Of Production

a flame colorant and flame technology, applied in the field of flame colorant devices, can solve the problem that newton does not teach the use of inorganic metal salt flame colorants, and achieve the effect of convenient combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

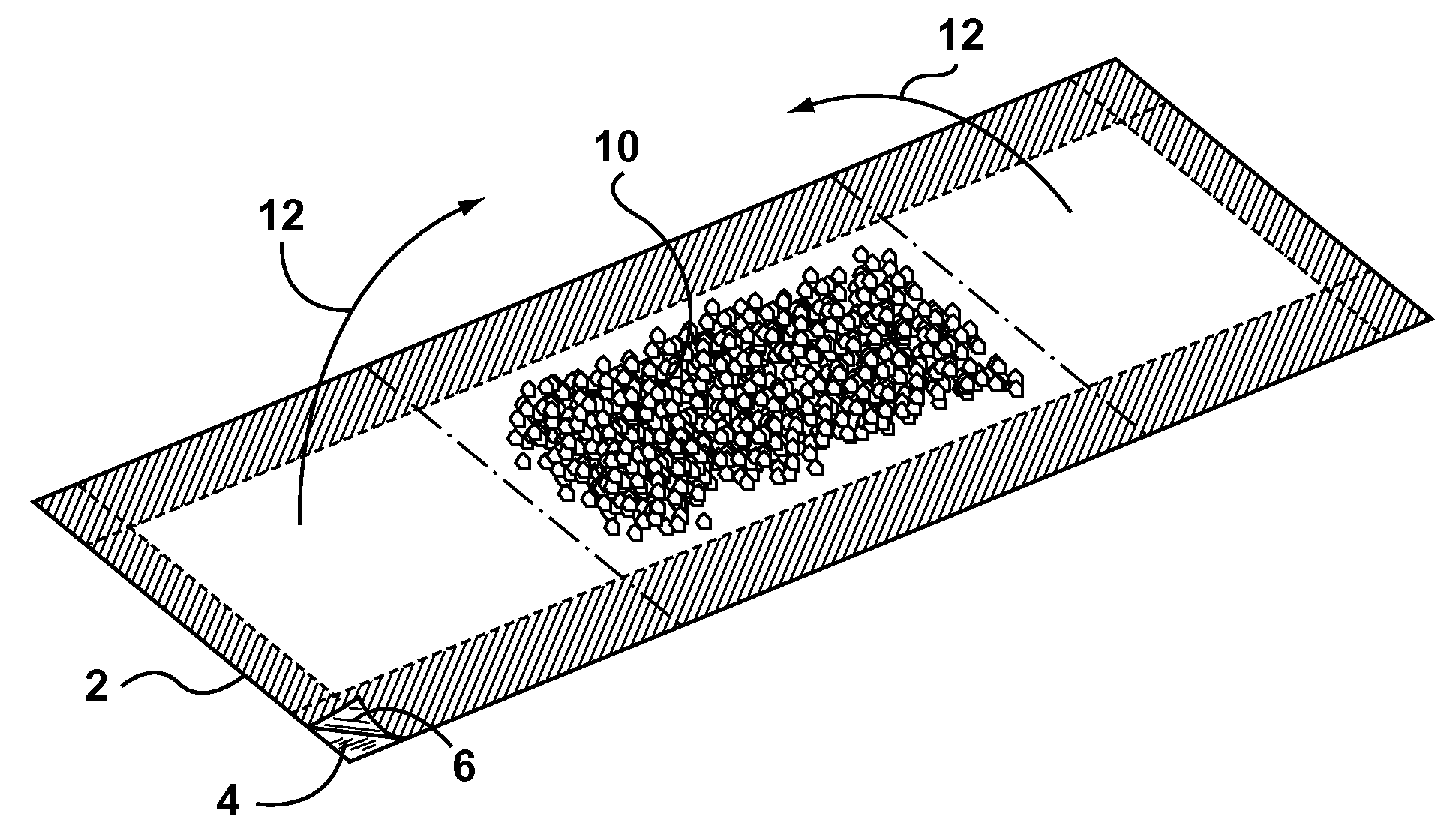

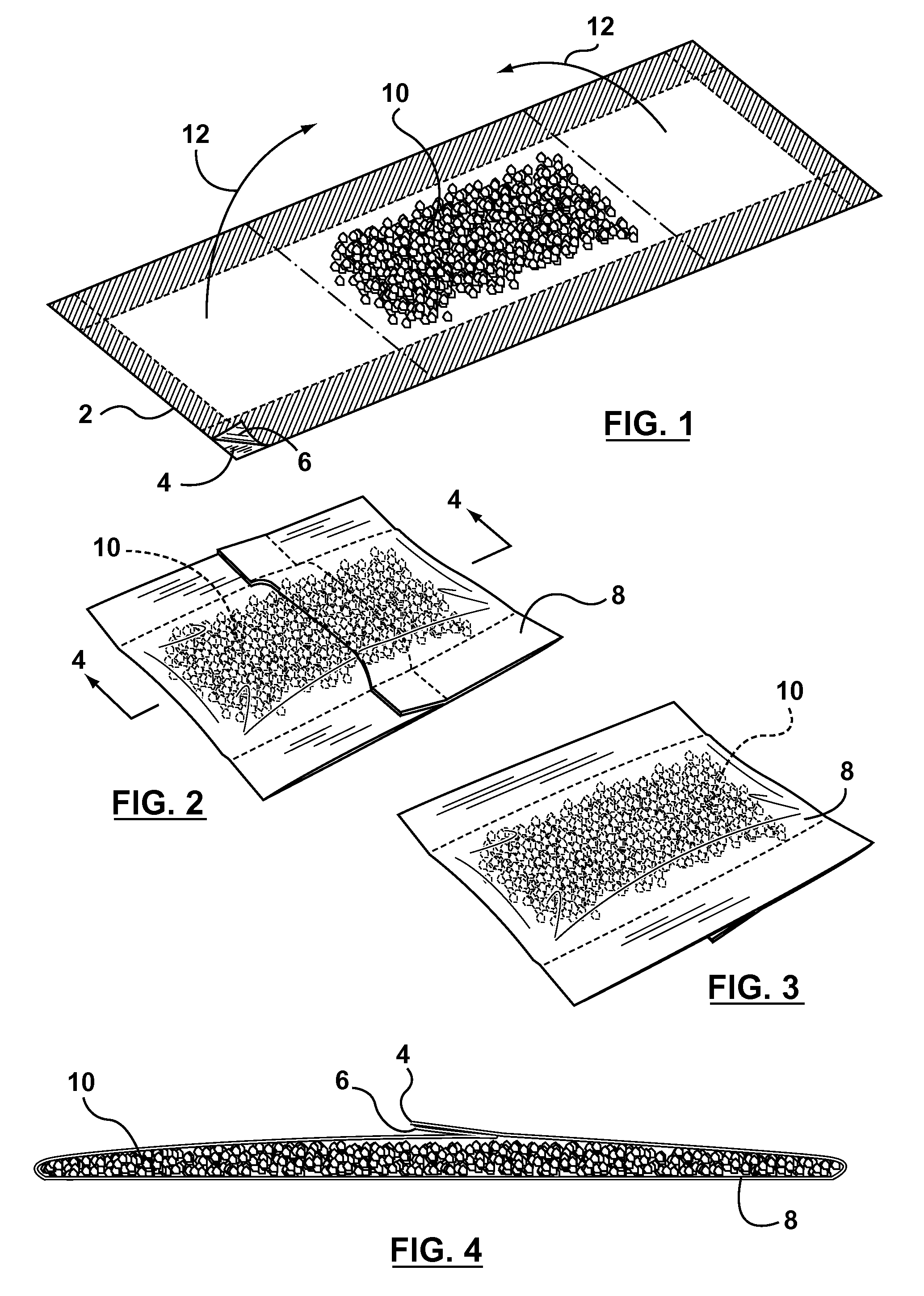

Image

Examples

Embodiment Construction

[0029]The present invention provides a composition having one or more flame colorant components and a drying agent. The flame colorant components are one or more inorganic metal salts. The flame colorant components are preferably selected from the group consisting of copper chloride, lithium chloride, copper sulphate, calcium chloride, potassium chloride, strontium chloride, sodium chloride and magnesium chloride. Each of these metal salts will produce a flame of a characteristic color when burned. The color corresponding to the flame produced by each salt is set out in the table below:

TABLE IColors Corresponding to Metal SaltsFlame ColorSaltbluecopper chloridecarminelithium chloridegreencopper sulphateorangecalcium chloridepurplepotassium chlorideredstrontium chlorideyellowsodium chloridewhitemagnesium chloride

[0030]The composition according to the invention also comprises a drying agent mixed with the flame colorant components. In a preferred embodiment, the drying agent is Micro-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com